|

Earl in Pensacola

|

|

« on: March 26, 2011, 01:33:43 PM » |

|

I had the steering head bearings replaced about 30K aback and it's time too "tighten her up a tad" just to get it back to about s 2 lb pull. I figured that the socket would be outrageously at $40 or even $50.. Ha Ha Ha I was just quoted $122.50 out the door!!!!

I've read a couple of times that a couple of you guys have made (cut) your own socket and it works. Is there still one of you willing to take chance and will loan your socket to me for a day or two?? I'd use it and return it with a check to cover the cost you paid to ship it to me. That is, unless your live close enough for me to come pick it up or even do the adjustment at your place. I'm assuming that it shouldn't take more than a few minutes.

I'm in Pensacola, Fl.

member 1983

justmeedp(nospam)@cox.net

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #1 on: March 26, 2011, 02:12:28 PM » |

|

what size nut is that.......Is it the same as the lock nut on the swing arm, cause I made a socket to fit that

|

|

|

|

|

Logged

Logged

|

|

|

|

|

|

John Schmidt

Member

Posts: 15240

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #3 on: March 26, 2011, 04:28:40 PM » |

|

Went to Harbor Freight and bought a 36mm deep socket for an impact wrench. When I got the nut uncovered, I set the socket on top and marked where the notches were, then cranked up my compressor. Using the die grinder with a cutting wheel, I made my own socket for that steering stem nut. Don't try using a hack saw, the socket is chrome moly alloy steel. So, if you have a compressor and die grinder with a cutting wheel, or know someone with access to one....make your own for future use. Well under $10 invested.

|

|

|

|

|

Logged

Logged

|

|

|

|

Disco

Member

Posts: 4899

Armed Man=Citizen; Unarmed Man=Subject

Republic of Texas

|

|

« Reply #4 on: March 27, 2011, 07:01:19 AM » |

|

Earl, if you're coming to Hotglue's GOTF, I'll have the DFW Toolkit with me. It has the Honda steering head tool in it.

|

|

|

|

|

Logged

Logged

|

2000 Bumblebee "Tourer", 98 Yellow & Cream Tourer, 97 Rescue blower bike 22 CRF450RL, 19 BMW R1250RT 78 CB550K 71 Suzuki MT50 Trailhopper .jpg) VRCC 27,916 IBA 44,783 |

|

|

fudgie

Member

Posts: 10613

Better to be judged by 12, then carried by 6.

Huntington Indiana

|

|

« Reply #5 on: March 27, 2011, 08:12:13 AM » |

|

Got mine from a goldwinger who made some years ago. got the link here. It was like $20 or close.

|

|

|

|

|

Logged

Logged

|

Now you're in the world of the wolves... And we welcome all you sheep... VRCC-#7196 VRCCDS-#0175 DTR PGR |

|

|

|

Ricky-D

|

|

« Reply #6 on: March 27, 2011, 09:34:59 AM » |

|

2 pound pull is about what you could achieve if you wrapped a rag around it and turned it with both hands.

I remember it was all about touch and feel with the wheel bearing nut on the front ends of the cars.

The worst case scenario is too tight and if the nut were to be a tad too loose there would be no adverse consequences arise from that.

The important part of tightening the nut is to have no external forces applying pressure to the steering stem assembly, in which case optimum would be to have the front wheel, shocks and handlebars removed.

Of course this is not really a real world solution since removing all that would involve a lot of work so the next best thing would be to try to unweight the front end the best you can prior to tightening the nut.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

fudgie

Member

Posts: 10613

Better to be judged by 12, then carried by 6.

Huntington Indiana

|

|

« Reply #7 on: March 27, 2011, 10:15:43 AM » |

|

Yea what Ricky said. Take the front wheel off. You might be surprised how loose it is without the weight. Mine was not noticeable till the front wheel was off. Bars flopped back and forth alot. I'm surprised you waited 30k to retourqe.  |

|

|

|

|

Logged

Logged

|

Now you're in the world of the wolves... And we welcome all you sheep... VRCC-#7196 VRCCDS-#0175 DTR PGR |

|

|

|

Earl in Pensacola

|

|

« Reply #8 on: March 27, 2011, 02:24:08 PM » |

|

Disco-- I won't be going to GOTF, but appreciate the offer. However, I am prepin' for a ride come May 15th.

Fudgie-- I have waited so long (30K) to re-torque because it's such a "pain-in-the-a$$". I'm hoping that I can get away with just removing the dog-bone clamp and moving the handle bars a little, removing the upper 30MM chrome nut, then going in with either an OEM or home-made tool. The race is not yet indexed. I just noticed that it's a little too free and want to snug it back to a 2 lb "drag".

|

|

|

|

|

Logged

Logged

|

|

|

|

fudgie

Member

Posts: 10613

Better to be judged by 12, then carried by 6.

Huntington Indiana

|

|

« Reply #9 on: March 27, 2011, 03:55:35 PM » |

|

You should be able to do all that without taking everything apart, if I remember. I believe I took my shield off and the chrome nut and got it from there. Then again I have longer risers.  |

|

|

|

|

Logged

Logged

|

Now you're in the world of the wolves... And we welcome all you sheep... VRCC-#7196 VRCCDS-#0175 DTR PGR |

|

|

|

Hook#3287

|

|

« Reply #10 on: March 27, 2011, 04:59:52 PM » |

|

What happens if it's to tight?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

lucky_1_chris

|

|

« Reply #11 on: March 28, 2011, 05:26:12 PM » |

|

I have one for the Goldwing/VTX. If it's the same socket I can drop it in the mail tomorrow. LMK.

|

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2016 Victory Cross Country Tour

|

|

|

|

Ricky-D

|

|

« Reply #12 on: March 29, 2011, 09:49:32 AM » |

|

What happens if it's to tight?

Probably the greatest possibility would be to lessen the life of the bearings. Maybe feeling a roughness in turning the handlebars from the accelerated wearing. Indexing the bearings is also a possibility, especially if the bike hits a curb or something like that which would put an additional impact force on the bearings. Stiffness in turning the handlebars. feeling a reluctance to easily turn in the handlebars. It would be most noticeable in poor low speed handling characteristics. *** |

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

Daniel Meyer

Member

Posts: 5493

Author. Adventurer. Electrician.

The State of confusion.

|

|

« Reply #13 on: March 29, 2011, 10:58:33 AM » |

|

I have one for the Goldwing/VTX. If it's the same socket I can drop it in the mail tomorrow. LMK.

It is the same socket. There's a guy on the goldwing list that makes them...a quality job at a nice price. What happens if it's to tight?

What Ricky-D said, and I'll add, poor wet weather performance/instability...the front end will feel like it's about to slide out from under you even on minor corners in the wet (and it will too!). Lots of "hunting" in the dry. The Valk is VERY picky about these bearings/setting. |

|

|

|

|

Logged

Logged

|

CUAgain, Daniel Meyer  |

|

|

|

BradValk48237

|

|

« Reply #14 on: March 31, 2011, 04:57:00 PM » |

|

On my I/S when I have it on the lift, the handlebars will easily flop side to side.... Wrong?

If so, anyone in the Detroit area have the socket???????

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Ricky-D

|

|

« Reply #15 on: April 01, 2011, 09:13:38 AM » |

|

On my I/S when I have it on the lift, the handlebars will easily flop side to side.... Wrong?

Other sources for information regarding steering stem tightness, discuss "fall away" as a qualitative measure of front end condition (steering stem tightness). The truly accurate measure for front end tightness is a guessing game akin to "about like this, or about like that". With cables and wiring attached to the front end along with added weight and "whatever" also hanging on the front end: trying to get it right is pretty difficult under most circumstances. Ideally the steering stem bearings should have no lateral play and additionally a slight preloaded condition to insure the bearing are correctly rolling rather than possibly sliding. Absent any lateral play in the bearings the assumption should be that conditions are acceptable regarding tightness. On the other hand a looseness in the bearings (slight lateral movement) will cause no damage but could cause other conditions affecting handling and ride-ability, not to mention aggravating noises and clicks. It's pretty easy to do a quick check for looseness of the steering stem bearings, of which I have recently posted in a recent thread by: F6CTrider and titled: I feel a little "click" in the handle bars..*** |

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

Daniel Meyer

Member

Posts: 5493

Author. Adventurer. Electrician.

The State of confusion.

|

|

« Reply #16 on: April 01, 2011, 09:16:27 AM » |

|

My experience with the Valk is that it is VERY picky about this. Your best bet is to retorque them...as in follow the manual steps.

And if you're gonna go that far, get some lube in there (honda did not lube these well).

And if you're gonna go that far, if you're over about 45k miles and they've never been retorqueud, check them for indexing and probably replace them.

|

|

|

|

|

Logged

Logged

|

CUAgain, Daniel Meyer  |

|

|

|

Chrisj CMA

|

|

« Reply #17 on: April 11, 2011, 12:50:47 PM » |

|

OK Earl, the grinding is done........I sure hope it fits......Jeff  |

|

|

|

|

Logged

Logged

|

|

|

|

|

98valk

|

|

« Reply #18 on: May 20, 2011, 06:32:36 PM » |

|

OK Earl, the grinding is done........I sure hope it fits......Jeff  any dimensions for those tabs ChrisJ? |

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

GOOSE

Member

Posts: 704

D.S. #: 1643

Southwest Virginia

|

|

« Reply #19 on: May 20, 2011, 07:26:27 PM » |

|

CHRIS...think about this for a moment.......why don't you make some, and i don't mean for free, and sell a few like the goldwinger that daniel was speaking of? there are probably a bunch of people on here that would buy one...myself included. now that you thought about it...what do you think? we are all waiting. john.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #20 on: May 20, 2011, 08:13:54 PM » |

|

OK CA......just happened to see your post here..........its a 36mm deep socket bad to the bone metal (Chrome moly) I think is what its made of. Its heavy duty axle nut socket, not your average autozone socket. the tabs (4 of them @ 12/3/6/9 o'clock are 1/4 inch wide and 5/16 inch high. I used a Roto-Zip hand grinder to shape it, and it wasnt that fun.

John, before I even think about making another, lets see if this one works......Earl is coming over Monday am to give a twist to the head bearing nut.....we are going to find out if the thing works. Im sure someone with a drill press grinder router thinggy made for maching metal could pop these things out in 5 minutes

|

|

|

|

« Last Edit: May 20, 2011, 08:19:21 PM by Chrisj CMA »

|

Logged

Logged

|

|

|

|

X Ring

Member

Posts: 3626

VRCC #27389, VRCCDS #204

The Landmass Between Mobile And New Orleans

|

|

« Reply #21 on: May 20, 2011, 08:23:29 PM » |

|

ChrisJ, is that an air impact socket?

Marty

|

|

|

|

|

Logged

Logged

|

People are more passionately opposed to wearing fur than leather because it's safer to harass rich women than bikers.  |

|

|

|

Chrisj CMA

|

|

« Reply #22 on: May 20, 2011, 08:30:26 PM » |

|

ChrisJ, is that an air impact socket?

Marty

Not tryin to be sarcastic, but I suppose it could be....its a 1/2" drive deep well heavy duty axle nut socket. Im sure an air impact driver would not hurt this bad boy |

|

|

|

|

Logged

Logged

|

|

|

|

Walküre

Member

Posts: 1270

Nothing beats a 6-pack!

Oxford, Indiana

|

|

« Reply #23 on: May 23, 2011, 12:26:32 AM » |

|

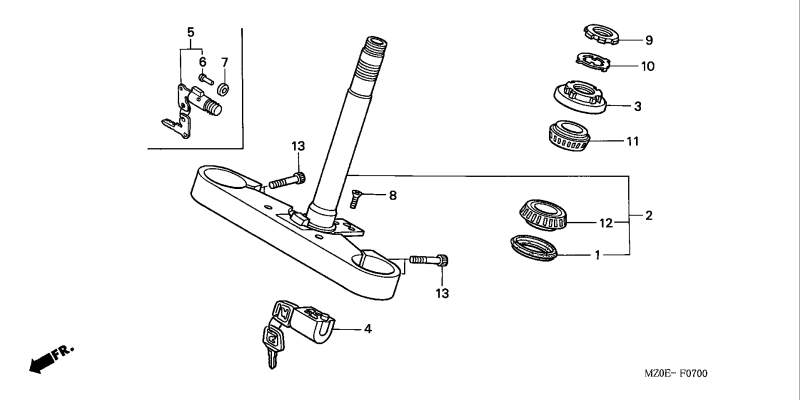

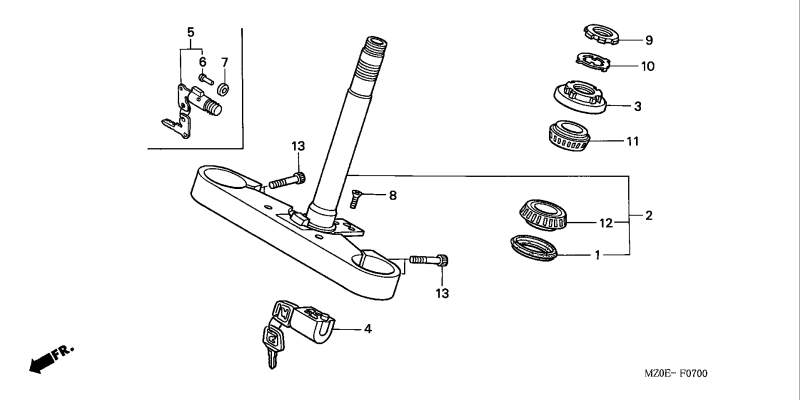

Chris - you mention that it's a 36mm socket. I checked our not-so-local Harbor Freight, and couldn't find it. I'm totally guessing here, but am I correct in assuming, that we are more concerned with the diameter, than the 36mm hex? I've not had mine apart, so I can't see it, but I'm guessing that we are making a spanner wrench, instead of actually using the hex part for a nut. Therefore, ANY socket, with the same diameter, would work? If that's the case, couldn't a piece of pipe, or similar, with the same diameter, have notches cut like the socket, and have a hole through it, and a bar for turning it,, something like this?:  Or, am I all wet? If that IS the case, do you have a way of measuring the outside diameter, of the socket? Like, with a micrometer, or dial calipers? And, how tight does the retainer tend to be? That's basically the preload on your bearings, correct? and the actual "holding" is done with the keyed "keeper" (#10 below), then the top nut (#9 below), to keep the adjustment? Where does the 30mm come it? Looks on the picture below, like it also uses a spanner... Again, assuming - in the illustration, #9 is the 30mm, but is it hex, or use a spanner also? And, #3 is the nut in question, that uses the 36mm modified socket? Guess I should just dig into mine, but would be nice to be totally prepared before I do. I am off next week, and plan to do a LOT to the bike, in preparation for a two-week trip towards the end of summer. I've done a lot already, but I don't mind doing preventative. thanks, to anyone who can enlighten me. R  |

|

|

|

« Last Edit: May 23, 2011, 12:29:50 AM by Walküre »

|

Logged

Logged

|

2000 Valkyrie Standard

1999 Valkyrie Interstate

2000 HD Dyna Wide Glide FXDWGRoger Phillips Oxford, IN VRCC #31978 Yeah, what she said...

|

|

|

|

Jess Tolbirt

|

|

« Reply #24 on: May 23, 2011, 04:06:37 AM » |

|

to me looking at the picture, it is NOT a hex head nut and neither is number 3 so yes you are correct,,,you tightem number 3just a tad more than hand tight, slip over the lock washer and run the #9 down as a lock nut and then you bend the tabs of the wahser to hold them in place...thats sorta the way i see it,,,

|

|

|

|

|

Logged

Logged

|

|

|

|

Walküre

Member

Posts: 1270

Nothing beats a 6-pack!

Oxford, Indiana

|

|

« Reply #25 on: May 23, 2011, 05:11:28 AM » |

|

Looks like that to me, too. What I wasn't seeing, was the capnut on top. That is the 30mm, or just under 1-3/16" (you can use the 1-3/16" with a rag to protect the chrome, and fit just about perfect). Then the rest should be self expkanatory, I would think . The diameter would still be nice to know .

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Standard

1999 Valkyrie Interstate

2000 HD Dyna Wide Glide FXDWGRoger Phillips Oxford, IN VRCC #31978 Yeah, what she said...

|

|

|

|

Misfit

|

|

« Reply #26 on: May 23, 2011, 06:43:30 AM » |

|

Chris - you mention that it's a 36mm socket. I checked our not-so-local Harbor Freight, and couldn't find it. I'm totally guessing here, but am I correct in assuming, that we are more concerned with the diameter, than the 36mm hex? I've not had mine apart, so I can't see it, but I'm guessing that we are making a spanner wrench, instead of actually using the hex part for a nut. Therefore, ANY socket, with the same diameter, would work? If that's the case, couldn't a piece of pipe, or similar, with the same diameter, have notches cut like the socket, and have a hole through it, and a bar for turning it,, something like this?:  Or, am I all wet? If that IS the case, do you have a way of measuring the outside diameter, of the socket? Like, with a micrometer, or dial calipers? And, how tight does the retainer tend to be? That's basically the preload on your bearings, correct? and the actual "holding" is done with the keyed "keeper" (#10 below), then the top nut (#9 below), to keep the adjustment? Where does the 30mm come it? Looks on the picture below, like it also uses a spanner... Again, assuming - in the illustration, #9 is the 30mm, but is it hex, or use a spanner also? And, #3 is the nut in question, that uses the 36mm modified socket? Guess I should just dig into mine, but would be nice to be totally prepared before I do. I am off next week, and plan to do a LOT to the bike, in preparation for a two-week trip towards the end of summer. I've done a lot already, but I don't mind doing preventative. thanks, to anyone who can enlighten me. R  I used a sears 36mm shallow socket. Cut it into and welded a piece of 17/8 OD pipe inbetween the two halves. So to answer your ?? 17/8 OD . |

|

|

|

|

Logged

Logged

|

If you're lucky enough to ride a Valkyrie, you're lucky enough.  |

|

|

|

Warlock

|

|

« Reply #27 on: May 23, 2011, 08:24:47 AM » |

|

I had the steering head bearings replaced about 30K aback and it's time too "tighten her up a tad" just to get it back to about s 2 lb pull. I figured that the socket would be outrageously at $40 or even $50.. Ha Ha Ha I was just quoted $122.50 out the door!!!!

I've read a couple of times that a couple of you guys have made (cut) your own socket and it works. Is there still one of you willing to take chance and will loan your socket to me for a day or two?? I'd use it and return it with a check to cover the cost you paid to ship it to me. That is, unless your live close enough for me to come pick it up or even do the adjustment at your place. I'm assuming that it shouldn't take more than a few minutes.

I'm in Pensacola, Fl.

member 1983

justmeedp(nospam)@cox.net

I went to the local hardware store and bought a hot water heater heating element removal tool and cut the end off and cut my notches in it. I then slide a screwdriver thru the 2 little holes and notched a socket to fit the screw driver so I could torque it. Sounds strange, but made the piece for under $5.00. David |

|

|

|

|

Logged

Logged

|

I don't want to hear the labor pains, I just want to see the baby |

|

|

|

Chrisj CMA

|

|

« Reply #28 on: May 23, 2011, 09:43:13 AM » |

|

OK< looks like I havent been keeping up here. Wew did the work on the Valkyrie front end. The tool did not fit, but we didnt really need it anyway. we just tapped the rings around with a scredriver and a small hammer.

That tool looking thing somone posted with the handle at the top is no good because the whole point is to put a torque wrench on it for initial assembly.

For our needs today it just needed a snug up, well quite a snug up, but we carefully tested the end play and swing of the forks, and made it only as tight as we needed to to get it to perform correctly......it rode great and felt perfect........

To fix the tool I need to take what looks like 2mm off the inside diameter (so a 38mm socket would work better.......plus a 1/6in off the width of each tooth and she should be perfect, so instead of 1/4 inch make the teeth 3/16in at 12,3,6,9 oclock on a 38mm socket and it should be good to go

|

|

|

|

« Last Edit: May 23, 2011, 09:46:47 AM by Chrisj CMA »

|

Logged

Logged

|

|

|

|

Walküre

Member

Posts: 1270

Nothing beats a 6-pack!

Oxford, Indiana

|

|

« Reply #29 on: May 23, 2011, 09:20:57 PM » |

|

OK< looks like I havent been keeping up here. Wew did the work on the Valkyrie front end. The tool did not fit, but we didnt really need it anyway. we just tapped the rings around with a scredriver and a small hammer. Normal for spanner nuts, the only thing I would be alert for, is metal chips and filings, that come off, dropping into bearings below, if it takes a LOT of pressure. Probably NOT the case here, just something to be aware of. That tool looking thing somone posted with the handle at the top is no good because the whole point is to put a torque wrench on it for initial assembly. Two cures, if I go with a pipe - either weld a flat on the end, and cut a 1/2" square n it with the plasma cutter, for a 1/2" drive torque wrench, or weld a cheapo MIC 1/2" socket on the flat. For our needs today it just needed a snug up, well quite a snug up, but we carefully tested the end play and swing of the forks, and made it only as tight as we needed to to get it to perform correctly......it rode great and felt perfect........ Great!! Love to hear success! Curious, did you do it with the bike suspended, or on the ground? In other words, all the sideways influences off the forks? I guess I could get out the manual, but my computer is at work (can't bring it home on the bike), and the manuals are at home, and I forget when I get there. Guess I'll write myself a note.  To fix the tool I need to take what looks like 2mm off the inside diameter (so a 38mm socket would work better.......plus a 1/6in off the width of each tooth and she should be perfect, so instead of 1/4 inch make the teeth 3/16in at 12,3,6,9 oclock on a 38mm socket and it should be good to go so, something I could do on the lathe, take 2mm off the inside. I didn't find a 38mm either, at Harbor Freight. Didn't take the time to check on their website - guess I'll add that to the note.  When I make mine, if it's easily done, I will probably make a bunch of them - usually it's just as easy for me to make 10 as one. And I'll probably use the socket approach - I have boxes of used sockets, that I've picked up over the years - used to do a lot of swap meeting, and would pick up boxes of tools, and often there were "made in Taiwan" sockets. Now, of course, they are all "made in China" sockets. Thanks for the info - will make doing my homework a lot easier. |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Standard

1999 Valkyrie Interstate

2000 HD Dyna Wide Glide FXDWGRoger Phillips Oxford, IN VRCC #31978 Yeah, what she said...

|

|

|

|

Chrisj CMA

|

|

« Reply #30 on: May 24, 2011, 04:50:12 AM » |

|

We had the front of the bike lifted for teh tightening sequence. We even had a fish scale, but with the bars and tripple clamp top removed neither of us was sure of what value to look for so we more or less had to guess based on how we know the front end should feel. Basically I think we chose well to stop tightening as soon as the play in the head bearings was eliminated, then backed off the nut to the first available match for the locking washer

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Ricky-D

|

|

« Reply #31 on: May 24, 2011, 07:05:49 AM » |

|

Normally a little bit of load is called for in head bearing adjustment.

So, when you get to a point where play is eliminated, an additional five or ten degrees of turn would be the appropriate measure to take.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|

Chrisj CMA

|

|

« Reply #32 on: May 24, 2011, 07:49:33 AM » |

|

Normally a little bit of load is called for in head bearing adjustment.

So, when you get to a point where play is eliminated, an additional five or ten degrees of turn would be the appropriate measure to take.

***

Im sure thats about right where it lays.......pretty hard to determine the exact moment the slop was taken up.......there was just a feel, as it tightenen when it felt right and the swing of the forks felt right....I know its not scientific, but we were dealing with a situation where these were fairly new bearings put in a few thousand miles ago, but the locking washer was improperly secured and the dang thing backed off. so we had an unknown condition, but we were not going to re replace the bearings if this worked, and it did.....bike rides perfect no signs of indexing and the owner was happy, so thats what matters |

|

|

|

|

Logged

Logged

|

|

|

|

|

Ricky-D

|

|

« Reply #33 on: May 24, 2011, 08:05:46 AM » |

|

Yeah, I don't feel that loose bearings will induce indexing, regardless of degree.

Indexing in my experience has always been a result of a frontal crash.

Loosely adjusted steering head bearings are just that and mainly affect feel of the front end.

A rideability issue!

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|