|

DK

|

|

« on: April 13, 2016, 07:33:56 PM » |

|

Although I've triked my '2000 Tourer, I'm sure my problem is with O.E. Valk components.

In the beginning, the brake rear pedal, although functioning properly the last time out, depressed fully without engaging the rear brakes. After pumping the pedal a couple of times the pedal firmed up and satisfactorily engaged the brakes. I stopped, checked the fluid level which was normal. It continued this way for the next 10 - 15 applications after which the pedal remained firm and functioned properly for the remainder of the 200 mile or so ride.

Next morning, the pedal again depressed fully and the same pattern repeated itself. I checked the fluid level which again was normal and then bled the brakes but didn't notice any air. The same pattern continued.

I installed a master cylinder rebuild kit, (The old seals looked ok) bled the system, and went for a road test. The first dozen or so stops were good and then; no pedal. It pumped up and now continues malfunction as previously described.

The thing I see possibly wrong is that the reservoir is somewhat distorted. It bulges out noticeably on the sides.

Any suggestions would be appreciated.

Dan

|

|

|

|

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

Tfrank59

Member

Posts: 1364

'98 Tourer

Western Washington

|

|

« Reply #1 on: April 14, 2016, 08:34:40 AM » |

|

"I'm sure my problem is with O.E. Valk components." Dan, how can you be sure it's the Valk components? It sounds like your system is sucking air somehow, and you need to figure out exactly where--I wouldn't rule out anything at the start. If you're not leaking fluid anywhere but the pedal goes soft after a while, then seems like somehow you're getting air in the system.

|

|

|

|

|

Logged

Logged

|

-Tom

Keep the rubber side down. USMC '78-'84

'98 Valkyrie, ‘02 VTX 1800, '96 Royal Star, '06 Drifter, '09 Bonneville, '10 KTM 530, '04 XR 650, '76 Bultaco, '81 CR 450, '78 GS 750...

|

|

|

|

Ricky-D

|

|

« Reply #2 on: April 14, 2016, 01:14:35 PM » |

|

It seems the problem is not with the master cylinder but rather at the caliper end. If there was air in the system you should not be

able to pump it up. The clue is, that you say the braking is good then after you pump it up. If true, that would mean the brakes are rubbing

considerably because of the pressure remaining in the line from pumping up. However, after sitting overnight, the system once again

needs pumping up. I think the seals on the pistons are sticking to the bore and causing the pistons to back up in the caliper and when you pump

them up, you're resetting the pistons back to their proper position.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|

DK

|

|

« Reply #3 on: April 14, 2016, 01:41:47 PM » |

|

Tom,

I've carefully checked for leaks in the system: no leaks, no stains on floor, no fluid loss in reservoir.

I've bled twice: no air in system. Also, it had been functioning perfectly for years and there was no precipating event I know of. No hard application, repair, wreck, bad bump etc. happened to cause this. It was fine when I parked it and the next morning it wasn't fine. The pedal is not spongy like it would be with air in the system; when the fail occurs, the pedal moves as it there is no fluid, i.e., if it weren't for the spring, the pedal would move downward from the force of gravity. Something is preventing fluid from flowing into the master cylinder bore for the piston to compress.

When the fail does not occur, the pedal is firm. You can hold it down hard for minutes without further downward movement.

The only obvious thing is the distortion of the reservoir. It's sides bulge outward preventing the cover from sealing correctly with the reservior. I've ordered a new one from Partszilla together with a new diaphragm and hose from reservior to master cylinder.

For now, I guess my primary question is whether the reservior must be completely sealed for the brakes to function properly?

|

|

|

|

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|

DK

|

|

« Reply #4 on: April 14, 2016, 01:55:40 PM » |

|

Ricky-D,

I'm sorry, I got interrupted while drafting the post and overlooked stating that the trike has drum brakes.

I've removed the drums and inspected the wheel cylinders and all other moving parts. The shoes actuate properly when the brake pedal is depressed. Everything is as it should be and the brakes are properly adjusted.

Can't believe I failed to state this. I don't think the drum brakes are a part of the problem but I should have mentioned at the outset.

Must a slight pressure be present in the master cylinder?

Why is the MC not vented? Without a vent, pressure will occur from the fluid heating up.

What is the purpose of the diaphragm?

|

|

|

|

« Last Edit: April 14, 2016, 02:02:47 PM by DK »

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|

longrider

|

|

« Reply #5 on: April 14, 2016, 04:51:07 PM » |

|

If you are sure there is no air in the system, and although you rebuilt the M/C, I would suspect a problem with the M/C and would replace the entire unit with a new one. You depend on the brakes.

|

|

|

|

|

Logged

Logged

|

|

|

|

Skinhead

Member

Posts: 8753

J. A. B. O. A.

Troy, MI

|

|

« Reply #6 on: April 14, 2016, 04:58:40 PM » |

|

If you have 2 drum brakes and are using the original Valkyrie Master, the problem may be that the mc doesn't flow a high enough volume of fluid on one stroke to pressurize both wheel cylinders. The Valk rear MC is designed for one caliper. I would look for a higher volume MC.

|

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

pancho

|

|

« Reply #7 on: April 14, 2016, 05:19:03 PM » |

|

"Why is the MC not vented? Without a vent, pressure will occur from the fluid heating up.

What is the purpose of the diaphragm?"

There actually is a vent,, the diaphragm separates the outside air from the inside of the master cylinder. As the fluid level changes, the outside air pressure allows the diaphragm to move up and down to equalize the pressure through the vent. You may have hit on the problem,,, the vent to the outside air may be clogged. It will just be a pinhole in the cap somewhere, I have never identified it in the rear master cylinder as I have never looked for it, but it is there.

|

|

|

|

|

Logged

Logged

|

The most expensive things you will purchase, are those things you would not have needed if you had listened and obeyed.

|

|

|

|

Paladin528

|

|

« Reply #8 on: April 14, 2016, 05:51:25 PM » |

|

drum brakes should have an adjuster that prevents the shes from "spreading" too much requiring more pedal to actuate. If that adjuster is not correctly set then the problem you describe can occur.

Since drum brakes usually set that adjustment in small increments when you REVERSE I suspect that the brakes are not self adjusting correctly. Adjust the adjuster byt turning it until you get a very slight drag.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

DK

|

|

« Reply #9 on: April 15, 2016, 04:02:47 PM » |

|

Thanks to everyone offering assistance. First, some responses to points various members have mentioned.

Drum brakes / wheel cylinders: The drum brakes have functioned satisfactorily (except when wet) during the 15,000 + miles I've rode the trike; the shoes are properly adjusted; and the wheel cylinders are good.

There is not a fluid leak anywhere in the system except for weeping around the MC lid due to the distortion of the reservior.

While waiting on new reservior, diaphragm& hose from Pinnacle, I've tightly sealed the MClid to the reservior with electrical tape and the system has functioned properly for the last 48 hours.

My theory at this point is that the diaphragm must seal the fluid from the atmosphere and the vent hole in the lid serves to equalize the pressure above the diaphragm. Because of the distortion of the reservior, the diaphragm is not sealing. I've found some support of this idea in automotive forums.

Still, I'm puzzled, doesn't quite make sense to me.

Dan

|

|

|

|

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|

rhinor61

|

|

« Reply #10 on: April 16, 2016, 11:14:29 AM » |

|

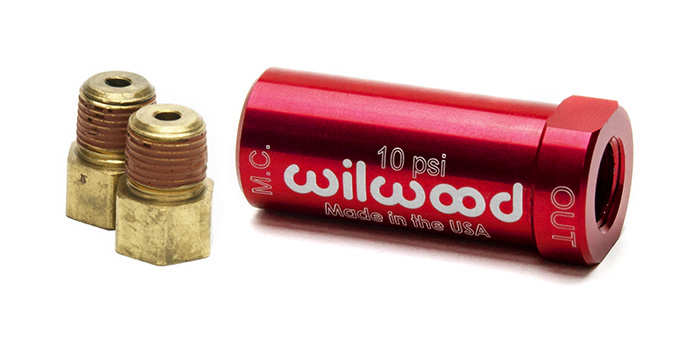

A disc brake master cylinders has a about 2lbs pressure residual valve to keep fluid out to the pistons. Drum brake require much more back pressure in the line otherwise the springs on the brake shoes will force the brake fluid back to the master cylinder. adding a inline brake line pressure residual valve will prevent the brake springs from forcing too much fluid back after your release your brakes.. from Wilwood. " Wilwood two pound and ten pound residual pressure valves retain a minimum brake line pressure to help eliminate excessive pedal travel in both disc and drum brake systems. The two pound valve is used in disc brake applications where the master cylinder is mounted below the horizontal plane of the calipers and fluid drain back occurs from gravity and vibration, thereby causing excessive caliper piston retraction and a longer brake pedal stroke. The minimal two pound residual pressure prevents fluid from flowing back without causing the brakes to drag. With drum brakes, a ten pound valve is used to compensate for return spring tension and maintain wheel cylinder sealing in the drums"  John |

|

|

|

|

Logged

Logged

|

John

Northern California

1998 Valkyrie Tourer Black/jade

VRCC #28001

|

|

|

|

DK

|

|

« Reply #11 on: April 17, 2016, 10:53:28 AM » |

|

John,

Thanks for the suggestion. I think it may very well be the solution. Even if not, it will definetly be a major improvement.

A question about the application of the regulator; do I install one downstream from the MC before the line branches to the wheels or do in install two, one for each wheel?

Also, should it be installed immediately after the MC or immediately before the wheel cylinder or does it matter?

Again, thanks.

Dan

|

|

|

|

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|

DK

|

|

« Reply #12 on: April 17, 2016, 04:59:41 PM » |

|

Results: Closing thread.

Successful fix: making distorted rear brake reservior airtight around seal with diaphram but leaving vent in reservior open to admit atmospheric pressure air above diaphram.

350 miles over 4 days with no problem.

I'm still awaiting delivery of new reservior & diaphram but in the meantime sealing he reservior by wrapping it tightly with 3M electrical tape but leaving vent open has cured the problem.

In any case however, I definatly intend to install the pressure regulator suggested by rhinor61.

Thanks to everyone for suggestions.

Dan

|

|

|

|

« Last Edit: April 17, 2016, 05:11:45 PM by DK »

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|