|

jblvalk

|

|

« on: April 24, 2018, 11:02:14 AM » |

|

So I have a '98 Tourer with 85k miles, and have decided to start the process of replacing the belts, and first is education for me. I have the shop manual, and have seen a handful of DYI's online. I adjusted the valves a few years ago and so I feel pretty comfortable tackling the timing belt. The first question I have is how do you release the tension on the idler pulley? The shop manual says take the spring off first and then loosen the nuts on the idler. The other DIY's say nothing about this and simply state to loosen the bolts on the idler. Secondly, when tensioning the idlers after installing the new belts, do you need a special tool? Is it enough to simply apply pressure to the idler until you have the desired slack and then quickly tighten the bolts? Want to have a clear understanding of all that needs to be done before I turn a single wrench  Sincerely appreciate any input on this. By the way, anyone in the Phoenix area have any experience with this as well? JBL |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bighead

|

|

« Reply #1 on: April 24, 2018, 03:08:15 PM » |

|

#1 Make sure the timing makes are aligned then loosing the idler bolts and remove then remove the 2 sensors replace belts . Then reverse the process I used a med length pry bar to hold the tension. Until I tightened the idler bolts I started mine and warmed up before I put the covers back so I could double check the tension. It is a very simple process I was nervous before I replaced mine. Was much simpler to do than my wife's Subaru.

On a second note how hard was it to adjust the valves? That is my next project

I will bet the valves will be in spec. |

|

|

|

|

Logged

Logged

|

1997 Bumble Bee

1999 Interstate (sold)

2016 Wing

|

|

|

|

Andy Cote

|

|

« Reply #2 on: April 24, 2018, 03:39:14 PM » |

|

When I checked the valve clearances on my 97 at 75,000 miles, they were consistently .001 out of tolerance. reset to mid range and buttoned up. The tappets are adjustable with a screwdriver and have a lock nut. No shims required.

Regarding the OP on tensioners. Easier to think backwards. The tensioners go on with bolts finger tight/snugged and the spring applying force to the belt. This is usually sufficient to give the right amount of movement on the opposite side. Then the tensioner locking bolt is tightened and the spring just sits there for the ride at that point. Not to say you can't force the tensioner one way or the other a wee bit before tightening the bolt to achieve the amount of free play that you prefer. No special tools required.

So back to the beginning, you can remove the tensioner bolts or springs first, Goal is to remove the tensioner.

MAKE SURE MARKS ARE ALIGNED BEFORE REMOVING TENSIONERS OR BELTS.

The covers can be removed from behind the radiator hose but it sure is easier to pull it out of the way. I view this as an excuse to replace the coolant with new.

Follow the multitude of online instructions and videos and this scary job becomes pretty routine. I would suggest you not do it when tired (like after work). Start early in the morning when you are fresh, take your time and you will finish this job with confidence before adult beverage time.

|

|

|

|

|

Logged

Logged

|

2015 Goldwing, basic black

Previously: 2000 Valkyrie Interstate, 1997 Valkyrie Standard, 1988 GL1500, GL1200 Standard, GL1200 Interstate and many other Hondas

|

|

|

|

da prez

|

|

« Reply #3 on: April 24, 2018, 03:42:37 PM » |

|

D O N O T start the bike after installing the timing belts. Remove the spark plugs and bar the engine over at least two revolutions. It is an interference engine. The valves will hit the pistons. If it stops turning , you have a problem. Before you turn it over , recheck the timing marks. Even if they are correct , bar it over by hand.

da prez

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Andy Cote

|

|

« Reply #4 on: April 24, 2018, 03:49:31 PM » |

|

Two one way, one backwards and another forward again.

|

|

|

|

|

Logged

Logged

|

2015 Goldwing, basic black

Previously: 2000 Valkyrie Interstate, 1997 Valkyrie Standard, 1988 GL1500, GL1200 Standard, GL1200 Interstate and many other Hondas

|

|

|

|

3W-lonerider

|

|

« Reply #5 on: April 24, 2018, 04:11:27 PM » |

|

i adjusted my valves this winter with 204,000 miles on the bike. last time they were adjusted it had 12,000 miles.

I found 3 exhaust valves 100 thousands tight but still within spec of factory. as far as the timimg belt tightness. do as others suggested, turn engine over by hand before hitting that starter.

heres how I adjust the timing belts. install belts and tensioners. do not tighten tensioners down.

install springs then put a wrachet or wrench on the crank bolt. turn just enough to tighten the the belt on the long side, the spring will set the tension on that belt and then tighten the tensioner, do the same for the opposite belt.

been doing it this way since iv'e had the bike. 200,000 miles and iv'e replaced the belts every 75,000.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Firefighter

|

|

« Reply #6 on: April 24, 2018, 04:20:43 PM » |

|

I used a paint pen to brighten the timing marks, makes life easier!

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Interstate, Black/Red

2006 Honda Sabre 1100

2013 Honda Spirit 750

2002 Honda Rebel 250

1978 Honda 750

|

|

|

Skinhead

Member

Posts: 8753

J. A. B. O. A.

Troy, MI

|

|

« Reply #7 on: April 24, 2018, 04:46:20 PM » |

|

as da prez said, and if you follow only one piece of advice make sure it is this, TURN THE ENGINE OVER BY HAND AT LEAST 2 REVOLUTIONS BEFORE HITTING THE STARTER! If you feel any significant resistance during this step, STOP! and check/realign your timing marks.

|

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

Harryc

|

|

« Reply #8 on: April 24, 2018, 04:59:28 PM » |

|

Good advice here. I just did this job last week. I also recommend making a second set of marks on the left and right cam gears with whiteout or white paint so that when you line up the factory marks you have a second set of reference points. TAKE THE SPARK PLUGS OUT FIRST!!!!. Lol

Compression alone can and will bend valve stems if the timing is not right and you spin the engine by hand with the plugs in. No plugs, no compression, and you get a second chance to do it right.

|

|

|

|

« Last Edit: April 24, 2018, 05:07:59 PM by Harryc »

|

Logged

Logged

|

|

|

|

Skinhead

Member

Posts: 8753

J. A. B. O. A.

Troy, MI

|

|

« Reply #9 on: April 24, 2018, 05:32:44 PM » |

|

Compression alone can and will bend valve stems if the timing is not right and you spin the engine by hand with the plugs in.

?????? ^^^^Please explain this^^^^^^^^ |

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

Ken aka Oil Burner

|

|

« Reply #10 on: April 24, 2018, 05:52:43 PM » |

|

Compression alone can and will bend valve stems if the timing is not right and you spin the engine by hand with the plugs in.

?????? ^^^^Please explain this^^^^^^^^ Well, I'm not Harry, but I'll give it a go. When you hand crank an engine with the plugs in, you'll feel the engine fight you at times, while you're pushing against compression building, and you'll feel it "spin forward" (move really easily, with no resistance) when you're turning hard and all of a sudden the compression releases due to valve opening. That fast spinning can bend a valve if there is an interference from incorrect setup. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harryc

|

|

« Reply #11 on: April 24, 2018, 06:26:23 PM » |

|

Well, I'm not Harry, but I'll give it a go. When you hand crank an engine with the plugs in, you'll feel the engine fight you at times, while you're pushing against compression building, and you'll feel it "spin forward" (move really easily, with no resistance) when you're turning hard and all of a sudden the compression releases due to valve opening. That fast spinning can bend a valve if there is an interference from incorrect setup.

It's been documented here many times ... |

|

|

|

« Last Edit: April 24, 2018, 06:28:29 PM by Harryc »

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #12 on: April 24, 2018, 08:19:10 PM » |

|

heres how I adjust the timing belts. install belts and tensioners. do not tighten tensioners down. install springs ..... - then put a wrachet or wrench on the crank bolt.

- turn just enough to tighten the the belt on the long side,

the spring will set the tension on that belt and then tighten the tensioner, do the same for the opposite belt. been doing it this way since iv'e had the bike. 200,000 miles and iv'e replaced the belts every 75,000. stated something similar in an earlier thread on the same topic ..... - Putting slight tension on the crank bolt in the direction that tightens the non slack side,

- then snug up the bolt in the adjuster slot.the tension should be near perfect.

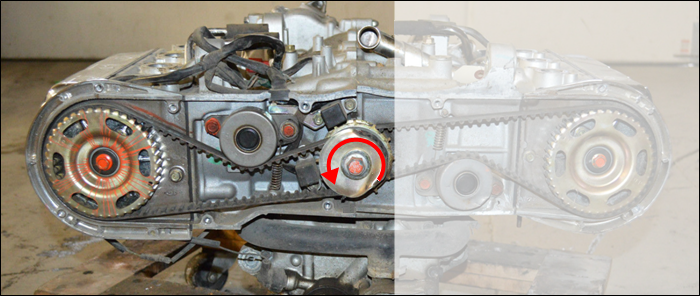

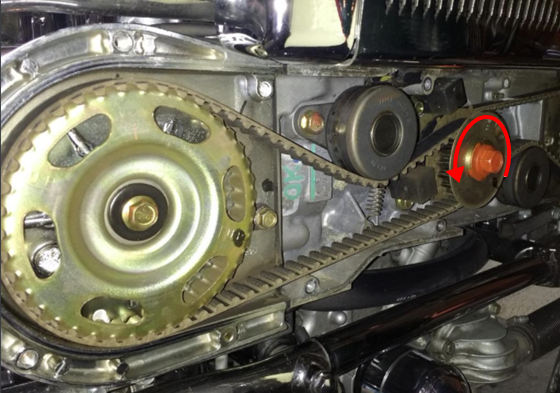

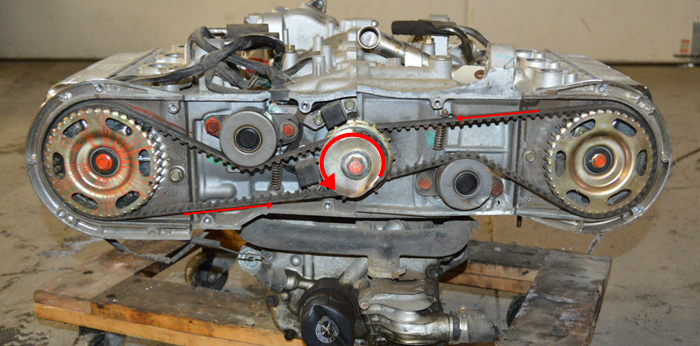

I've used this method on literally hundreds of car motors with this setup(mostly hondas) and never had a single failure or had to to retension it. I gather it accomplishes the same thing that pressing down a little on the tensioner does ..... it adds a smidgen more tension to what the coil spring already exerts on the belt(?), or insures the tension of the coil spring. Is this the correct way to turn the crankshaft pulley before torquing down the tensioner bolts?? I'm pretty sure it is. Below, adjusting the tension on the right-side belt.   |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

Skinhead

Member

Posts: 8753

J. A. B. O. A.

Troy, MI

|

|

« Reply #13 on: April 25, 2018, 05:12:53 AM » |

|

Compression alone can and will bend valve stems if the timing is not right and you spin the engine by hand with the plugs in.

?????? ^^^^Please explain this^^^^^^^^ Well, I'm not Harry, but I'll give it a go. When you hand crank an engine with the plugs in, you'll feel the engine fight you at times, while you're pushing against compression building, and you'll feel it "spin forward" (move really easily, with no resistance) when you're turning hard and all of a sudden the compression releases due to valve opening. That fast spinning can bend a valve if there is an interference from incorrect setup. I get what you are saying, but it is NOT compression (cylinder pressure) that bends a the valve, the valves operate normally under higher compression than will be generated turning the engine over by hand. In your scenario, what bends the valve is contact with the top of the piston as the valve and piston trying to occupy the same piece of real estate. All due to incorrect timing. |

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

jblvalk

|

|

« Reply #14 on: April 25, 2018, 05:48:09 AM » |

|

Secondly, when tensioning the idlers after installing the new belts, do you need a special tool? Is it enough to simply apply pressure to the idler until you have the desired slack and then quickly tighten the bolts?

JBL

The valve job was pretty intimidating at first, but after reading plenty of diy's online and reviewing thoroughly the procedure in the manual, I dove in. It really is a pretty easy thing to do. The only thing I recommend is completely familiarizing yourself with the procedure before you begin, don't rush, and to steal a suggestion from another poster, do it when you are fresh and not after work. You can really save yourself some $$ if you do this as most dealers will charge several hundred dollars for this service. Plus, the added inconvenience of leaving your bike overnight because they have to do this with the engine cold. |

|

|

|

|

Logged

Logged

|

|

|

|

|

jblvalk

|

|

« Reply #15 on: April 25, 2018, 05:56:18 AM » |

|

Follow the multitude of online instructions and videos and this scary job becomes pretty routine. I would suggest you not do it when tired (like after work). Start early in the morning when you are fresh, take your time and you will finish this job with confidence before adult beverage time.

Thank you and to everyone for their input. Lastly, have you guys bought the Gates Belts or gone with the Honda OEM? |

|

|

|

|

Logged

Logged

|

|

|

|

|

da prez

|

|

« Reply #16 on: April 25, 2018, 06:21:35 AM » |

|

Gates are better buy. I have used several sets. I think Rock auto has them for $18.00 each.

da prez

|

|

|

|

|

Logged

Logged

|

|

|

|

|

0leman

|

|

« Reply #17 on: April 25, 2018, 07:09:24 AM » |

|

I replaced my belts (106K) last winter. Removed the spark plugs first thing as was recommended. With them gone, there was no movement. I did use a sharpie to mark the wheels location. Took longer to get to the belts than it took to replace them. Used Gates belts. Yes, I did turn the engine over several times to make sure all was well. Have put 5-7K on her since then.

I have not really noticed any difference, other than piece of mind knowing the belts have been replaced. The old belts looked good, no cracks nor other signs of aging.

|

|

|

|

|

Logged

Logged

|

2006 Shadow Spirit 1100 gone but not forgotten

1999 Valkryie I/S Green/Silver

|

|

|

|

jblvalk

|

|

« Reply #18 on: April 25, 2018, 08:27:33 AM » |

|

heres how I adjust the timing belts. install belts and tensioners. do not tighten tensioners down.

install springs then put a wrachet or wrench on the crank bolt. turn just enough to tighten the the belt on the long side, the spring will set the tension on that belt and then tighten the tensioner, do the same for the opposite belt.

What do you mean by the "long side"? Which bolt is the crank bolt? Sorry man I am looking at a diagram of the belts and tensioners and I can't make heads or tails of what you're referring to? |

|

|

|

|

Logged

Logged

|

|

|

|

|

Ken aka Oil Burner

|

|

« Reply #19 on: April 25, 2018, 10:30:00 AM » |

|

Compression alone can and will bend valve stems if the timing is not right and you spin the engine by hand with the plugs in.

?????? ^^^^Please explain this^^^^^^^^ Well, I'm not Harry, but I'll give it a go. When you hand crank an engine with the plugs in, you'll feel the engine fight you at times, while you're pushing against compression building, and you'll feel it "spin forward" (move really easily, with no resistance) when you're turning hard and all of a sudden the compression releases due to valve opening. That fast spinning can bend a valve if there is an interference from incorrect setup. I get what you are saying, but it is NOT compression (cylinder pressure) that bends a the valve, the valves operate normally under higher compression than will be generated turning the engine over by hand. In your scenario, what bends the valve is contact with the top of the piston as the valve and piston trying to occupy the same piece of real estate. All due to incorrect timing. You're absolutely right. The compression doesn't bend the valve. I think what Harry was saying is that the engine having compression can lead to a bent valve when spinning over the engine by hand, if the setup is wrong. The compression won't bend a valve, but the engine having compression causes the uneven spinning speed that can lead to a bent valve if the setup is not correct. In retrospect, I shouldn't have butted in. I more explained the condition that causes the potential for valve damage, rather than what physically bends the valve(s). |

|

|

|

|

Logged

Logged

|

|

|

|

|

3W-lonerider

|

|

« Reply #20 on: April 25, 2018, 04:09:09 PM » |

|

heres how I adjust the timing belts. install belts and tensioners. do not tighten tensioners down.

install springs then put a wrachet or wrench on the crank bolt. turn just enough to tighten the the belt on the long side, the spring will set the tension on that belt and then tighten the tensioner, do the same for the opposite belt.

What do you mean by the "long side"? Which bolt is the crank bolt? Sorry man I am looking at a diagram of the belts and tensioners and I can't make heads or tails of what you're referring to? the long side is the side to which there is no tensioner. tensioner is on the short side. if you look at the pic that was posted you'll see the tensioner on the left side as the pic is shown to be on the top side. so the long side is the bottom of the belt. reverse it for the other side. tensioner is on the bottom, long side on top. the crank is the center pulley that has the trigger wheel installed behind it. that's what you will put the socket or wrench on. heres how I adjust the timing belts. install belts and tensioners. do not tighten tensioners down. install springs then put a wratchet or wrench on the crank bolt. turn just enough to tighten the the belt on the long side, the spring will set the tension on that belt and then tighten the tensioner, do the same for the opposite belt. |

|

|

|

« Last Edit: April 25, 2018, 04:11:43 PM by 3W-lonerider »

|

Logged

Logged

|

|

|

|

|

jblvalk

|

|

« Reply #21 on: April 25, 2018, 05:49:52 PM » |

|

the long side is the side to which there is no tensioner. tensioner is on the short side. if you look at the pic that was posted you'll see the tensioner on the left side as the pic is shown to be on the top side. so the long side is the bottom of the belt. reverse it for the other side. tensioner is on the bottom, long side on top. the crank is the center pulley that has the trigger wheel installed behind it. that's what you will put the socket or wrench on. heres how I adjust the timing belts. install belts and tensioners. do not tighten tensioners down. install springs then put a wratchet or wrench on the crank bolt. turn just enough to tighten the the belt on the long side, the spring will set the tension on that belt and then tighten the tensioner, do the same for the opposite belt. Thanks! |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #22 on: April 26, 2018, 09:37:22 AM » |

|

you can't go wrong if you turn the crankshaft pulley counter-clockwise. This pulls taunt the rung without the tensioner on both left and right side belts. Also slackens the rung that has the tensioner a smidgen. The slack allows the coil spring to pull the tensioner down just that little more. Actually creates the proper conditions for the coil spring to set the tension.  |

|

|

|

« Last Edit: April 26, 2018, 10:21:27 AM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

Skinhead

Member

Posts: 8753

J. A. B. O. A.

Troy, MI

|

|

« Reply #23 on: April 26, 2018, 10:54:02 AM » |

|

Compression alone can and will bend valve stems if the timing is not right and you spin the engine by hand with the plugs in.

?????? ^^^^Please explain this^^^^^^^^ Well, I'm not Harry, but I'll give it a go. When you hand crank an engine with the plugs in, you'll feel the engine fight you at times, while you're pushing against compression building, and you'll feel it "spin forward" (move really easily, with no resistance) when you're turning hard and all of a sudden the compression releases due to valve opening. That fast spinning can bend a valve if there is an interference from incorrect setup. I get what you are saying, but it is NOT compression (cylinder pressure) that bends a the valve, the valves operate normally under higher compression than will be generated turning the engine over by hand. In your scenario, what bends the valve is contact with the top of the piston as the valve and piston trying to occupy the same piece of real estate. All due to incorrect timing. You're absolutely right. The compression doesn't bend the valve. I think what Harry was saying is that the engine having compression can lead to a bent valve when spinning over the engine by hand, if the setup is wrong. The compression won't bend a valve, but the engine having compression causes the uneven spinning speed that can lead to a bent valve if the setup is not correct. In retrospect, I shouldn't have butted in. I more explained the condition that causes the potential for valve damage, rather than what physically bends the valve(s). I now understand what you meant and agree, if there is compression in a cylinder, once That piston gets beyond TDC, the pressure could spin the crank and cause a bent valve IF the timing marks are off. If they aren't, all is hunky dory. |

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

jblvalk

|

|

« Reply #24 on: April 26, 2018, 01:21:40 PM » |

|

The shop manual calls for coating the tensioner bolts with a "Locking Agent". What is that and I assume you can buy it at a local auto parts store??

|

|

|

|

|

Logged

Logged

|

|

|

|

|

The emperor has no clothes

|

|

« Reply #25 on: April 26, 2018, 02:11:19 PM » |

|

The shop manual calls for coating the tensioner bolts with a "Locking Agent". What is that and I assume you can buy it at a local auto parts store??

Locktite. I think Walmart even carry’s it. |

|

|

|

|

Logged

Logged

|

|

|

|

|

jblvalk

|

|

« Reply #26 on: April 26, 2018, 02:24:33 PM » |

|

The shop manual calls for coating the tensioner bolts with a "Locking Agent". What is that and I assume you can buy it at a local auto parts store??

Locktite. I think Walmart even carry’s it. Thank you. |

|

|

|

|

Logged

Logged

|

|

|

|

|