mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« on: August 23, 2019, 10:06:32 PM » |

|

My inner geek has been shouting on the rear assembly with the orings... so I just had to understand how/why the thing is supposed to work... since I havent been able to get mine together...  I bought an extra O-ring holder to try to figure it out..... Its really impossible to see the one on the bike what it looks like. But now I have eyes on the bastard...  What struck me is the groove for the oring is not really a groove its just wide allowing a lot of slop for the oring. Kinda poor design....  - (You design a slot for an oring, you make it so it doesnt move. )   |

|

|

|

« Last Edit: August 23, 2019, 10:41:13 PM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #1 on: August 23, 2019, 10:11:41 PM » |

|

On the flange the top part has a really sharp edge on it - the oring is catching on it. - I decided to file/polish a bit of a lead in chamfer on it...  |

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #2 on: August 23, 2019, 10:19:17 PM » |

|

Redeye on the oring holder...  Top down shot  What I didnt photo is that 2 OEM rings fit side by side in the groove nicely like its made to be that way... (things that make you go.. hmmm) |

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #3 on: August 23, 2019, 10:22:39 PM » |

|

Ok - so the oring holder (no ring) - slides thru the flange part very simply, nothing is catching....  |

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #4 on: August 23, 2019, 10:25:30 PM » |

|

Adding either Redeye or OEM shows it catches the front of the flange.  So this kinda confirms that the orings will be compressed as part of installation. It not a strait slide on... |

|

|

|

« Last Edit: August 23, 2019, 10:32:23 PM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #5 on: August 23, 2019, 10:29:59 PM » |

|

So with that, even the slightest screwball movement will catch the oring and grab it sideways...   |

|

|

|

« Last Edit: August 24, 2019, 05:45:35 AM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #6 on: August 23, 2019, 10:37:00 PM » |

|

Ok so what am I gonna do? I havent decided... .pray for some install luck? tons more lube it and grease? We shall see, but I have a better idea of what is going on. I really dont get how some of you guys seemingly nonchalantly slip new rings in and it all goes together no hassle..  Why did I post this? Dunno, kinda curious as to comments like throwing spaghetti against the wall and see waht sticks...  |

|

|

|

« Last Edit: August 23, 2019, 10:50:33 PM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

|

Avanti

|

|

« Reply #7 on: August 23, 2019, 11:02:20 PM » |

|

There is such a thing as an O-Ring with a Square Cross-Section.

|

|

|

|

|

Logged

Logged

|

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #8 on: August 24, 2019, 12:24:05 AM » |

|

There is such a thing as an O-Ring with a Square Cross-Section.

Very true.. why didnt Honda spec that? |

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

|

98valk

|

|

« Reply #9 on: August 24, 2019, 02:35:55 AM » |

|

Great Post.  bookmarked  |

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

|

The emperor has no clothes

|

|

« Reply #10 on: August 24, 2019, 03:08:19 AM » |

|

I think without grease on there it would do that 9 times out of 10. You might be over thinking this procedure. Put that sucker together and ride !

|

|

|

|

|

Logged

Logged

|

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #11 on: August 24, 2019, 04:58:03 AM » |

|

I think without grease on there it would do that 9 times out of 10. You might be over thinking this procedure. Put that sucker together and ride !

Very possible on the over thinking part.. you've seen most of my sh!t and yeah, it's kinda what I do..lol,..  .... I forgot to mention that I was using some motor oil on assembly trials so it wasn't bone dry. I'm wondering if the old oring holder can be pulled out and the new one pressed in......looking in the FSM......  My temptation?.... I think if I have learned anything is the oring holder, oring groove needs to be clean as possible. The oring needs to bite into the groove.. If you grease it before oring install, you increase the chance of the thing slipping. I 'm tempted to alcohol clean it, then finesse a fine layer of aircraft gasket glue in the groove and then stick the oring in and let set overnight...... then do the grease it up thing....... yeah I may be crazy....  But this damn bike has to go together.... season is slipping away... I would go nuts if I didn't have the VFR to ride..... |

|

|

|

« Last Edit: August 26, 2019, 02:02:18 AM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

Valkpilot

Member

Posts: 2151

What does the data say?

Corinth, Texas

|

|

« Reply #12 on: August 24, 2019, 05:08:49 AM » |

|

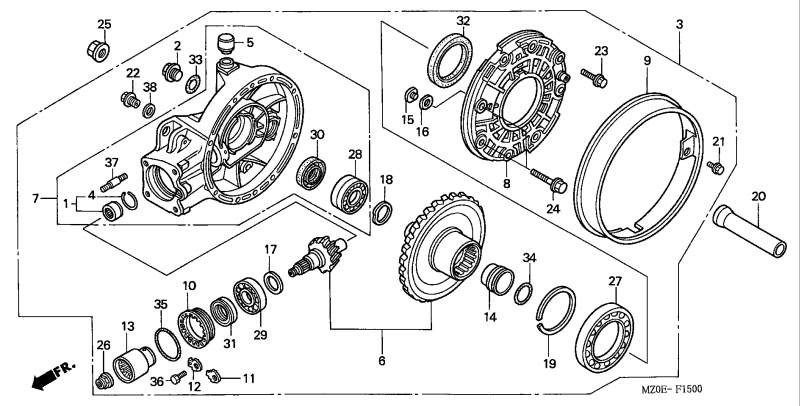

In 16 years and at least 20 final drive services, I've never experienced the difficulty you're having with reassembling the rear wheel. So far as I remember, your difficulty is unique. Part number 20 has been whispering to me as I read your posts.  This is part of the spacing system that helps maintain correct side-to-side distance across the rear wheel assembly. Part 20 matches up to a spacer inside the wheel which matches up to a spacer on the brake side to form a rigid column of the proper width to stabilize the whole assembly. Here's the thing. It's easy to install part 20 backwards. It's even shown backwards on parts diagrams like the one above. It has a flared end. This flared end goes out when you put the part in the final drive. If the flared end is put into the drive instead, it will not seat correctly and will keep the assembly from coming back together, i.e., the spacing will be off. When in properly, it will feel solidly locked in the final drive. When not, it will tend to be wobbly. It may wedge in place, but it will be sticking out too far. Whether or not this is the issue, I don't think you have an o-ring problem. However, you've highlighted something that has been mentioned before. In order to avoid deformation and possibly cutting the o-ring in your pictures, it is essential that the driven flange be inserted into the drive perfectly straight. You can't push it in at an angle or "tip" it up and in. To help make sure it goes in straight, insert the axle through the wheel before moving the wheel over to mate with the final drive. |

|

|

|

|

Logged

Logged

|

VRCC #19757 IBA #44686 1998 Black Standard 2007 Goldwing   |

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #13 on: August 24, 2019, 05:25:56 AM » |

|

Hey pilot... thanks for your post... 20 times? Voice of experience...

I haven't touched the spacer out of the pumpkin so it's as factory.... I will double check it anyway..

And I do get the assembly with using the axle as a guide to insure it goes on square and straight.....

|

|

|

|

« Last Edit: August 24, 2019, 05:32:42 AM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

Tfrank59

Member

Posts: 1364

'98 Tourer

Western Washington

|

|

« Reply #14 on: August 24, 2019, 07:17:00 AM » |

|

Redeye on the oring holder...  Top down shot  What I didnt photo is that 2 OEM rings fit side by side in the groove nicely like its made to be that way... (things that make you go.. hmmm) I'm a machinist and work in hydraulics so I cut o-ring grooves constantly. you can't have an oring groove that's the same width as the oring--it won't have room to expand. the groove width on these final drive parts are (my guess) right to spec, so you'd mess things up trying to put two orings in that groove. I think it's just a matter of having things properly aligned and lubed when you do the assy. |

|

|

|

|

Logged

Logged

|

-Tom

Keep the rubber side down. USMC '78-'84

'98 Valkyrie, ‘02 VTX 1800, '96 Royal Star, '06 Drifter, '09 Bonneville, '10 KTM 530, '04 XR 650, '76 Bultaco, '81 CR 450, '78 GS 750...

|

|

|

|

Ricky-D

|

|

« Reply #15 on: August 24, 2019, 08:04:01 AM » |

|

That groove is wide like that for a reason that, Honda determined it to be necessarily wide.

I surmise the reason to be coached in the fact, that the flange is not tightly held in rigid alignment but rather allowed to wallow around when the bike is accelerating or decelerating.

I think they determined that if the o-ring was held tightly such as in a normal o-ring groove, the wear on the o-ring would be unacceptable.

Now we all know the flange wallows around constantly because that is the reason for the thrust washer.

The wear on the bearing hub from the flange is beyond unacceptable when running without the thrust washer. We've all seen pictures of the damage.

That is the reason for the free groove for the o-ring.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #16 on: August 24, 2019, 08:19:57 AM » |

|

^^^^^Good stuff guys  Makes my brain spin some more.. Would really like to know from you guys who have the pumpkin and everything apart..... is the oring holder a pressed in part or a slip fit or..... The FSM 12-14/15/16 doesn't really mention it or show it on the exploded view... I see it on the engineering drawing ... 12-16 just says install oring....... |

|

|

|

« Last Edit: August 24, 2019, 11:42:47 AM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

|

indybobm

|

|

« Reply #17 on: August 25, 2019, 03:16:28 PM » |

|

It is pressed in. Another reason for the thrust washer is that it is steel against aluminum without it.

|

|

|

|

|

Logged

Logged

|

So many roads, so little time

VRCC # 5258

|

|

|

|

RonW

|

|

« Reply #18 on: August 25, 2019, 04:21:41 PM » |

|

Great pics!! Makes you wonder though on re-installing a rear wheel. I haven't taken the pumpkin apart, however bscrive in a reply to Fritz The Cat stated ..... "..... The holder is recessed a little into the main gear, but not by much, maybe /8". *⅛-inch, I think is what he meant. The relevant point being the o-ring holder is indeed press fitted in the ring gear though with only a ⅛-inch overlap. Apparently, the ⅛-inch overlap makes it possible to remove the o-ring holder using a dowel or pipe of appropriate diameter to work the o-ring holder loose. They used the axle shimmed tight to the inner barrel of o-ring holder. |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #19 on: August 25, 2019, 04:44:03 PM » |

|

It is pressed in. Another reason for the thrust washer is that it is steel against aluminum without it.

Thank you for that... I have given the one on the bike gentle tugs to see if it comes out, but no luck... Now I see why.... |

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #20 on: August 25, 2019, 05:17:25 PM » |

|

I think I am progressing... on the ID of the flange, I have been doing more polishing on it... a whole lotta wet sand work and elbow grease to polish the liven sh!t outta it. .. ... 3000 grit, then 5000, then 7000.... make it look purty.. Cant get a good photo... doesnt come out.... But I think I got this nailed. I did a tick (engineering unit) more work on the front edge chamfer I added, and the rings slip into position for install now fairly simply. Also now with the super smooth surface, and for practice, I can get either oring with lubing the ID with motor oil..- redeye or OEM to slip in, sliiiiiide in easy, in.... out......in.....out.... yes baby.... OEM Oring pushed into position for full install....  Redeye pushed into position for install  |

|

|

|

« Last Edit: August 26, 2019, 01:38:20 AM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #21 on: August 25, 2019, 05:29:06 PM » |

|

Like I said, I think this is nailed.. I hope to get a wheel test install this week and then I can close the book on the frickn thing...

Thoughts on it? On the one hand, I'm kinda annoyed I had it together in June, its a very low mile bike and probly didnt need all these gyrations, then on the other hand, I did learn plenty about the rear assembly...

|

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

|

98valk

|

|

« Reply #22 on: August 25, 2019, 06:27:27 PM » |

|

Like I said, I think this is nailed.. I hope to get a wheel test install this week and then I can close the book on the frickn thing...

Thoughts on it? On the one hand, I'm kinda annoyed I had it together in June, its a very low mile bike and probly didnt need all these gyrations, then on the other hand, I did learn plenty about the rear assembly...

|

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

Valkpilot

Member

Posts: 2151

What does the data say?

Corinth, Texas

|

|

« Reply #23 on: August 26, 2019, 05:57:36 AM » |

|

Hey pilot... thanks for your post... 20 times? Voice of experience...

I haven't touched the spacer out of the pumpkin so it's as factory.... I will double check it anyway..

And I do get the assembly with using the axle as a guide to insure it goes on square and straight.....

Like I said, I think this is nailed.. I hope to get a wheel test install this week and then I can close the book on the frickn thing...

Thoughts on it? On the one hand, I'm kinda annoyed I had it together in June, its a very low mile bike and probly didnt need all these gyrations, then on the other hand, I did learn plenty about the rear assembly...

Continuing to think about this, part 20 doesn't come into play until you are assembling the wheel on the axle, not when you're just pushing the driven hub into the rear drive. Speaking of that, just pushing the driven hub, without the wheel, into the drive, is extremely difficult. I don't think it's representative of install conditions. As I said before, what you are experiencing is very, very unusual, so all these hoops you're jumping through are likely completely unnecessary. They may "solve" your problem without ever addressing the root cause of what really kept the assembly from going together before. |

|

|

|

|

Logged

Logged

|

VRCC #19757 IBA #44686 1998 Black Standard 2007 Goldwing   |

|

|

|

Bagger John - #3785

|

|

« Reply #24 on: August 26, 2019, 08:17:18 AM » |

|

In 16 years and at least 20 final drive services, I've never experienced the difficulty you're having with reassembling the rear wheel. So far as I remember, your difficulty is unique.

I've owned Valkyries for 19 years, had as many as 5 at one time. Probably 20 tire changes of my own and dozens upon dozens of final drive/spline servicing and tire changes for fellow Valkyrie owners. If the parts are clean and in proper alignment, the O rings are new (not cut or deformed), thrust washer in place and fresh grease/moly paste where it belongs then everything will fit together correctly with no damage or deformation to any part of the assembly. Correct orientation and alignment is key, as was pointed out above. |

|

|

|

|

Logged

Logged

|

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #25 on: September 01, 2019, 05:55:07 PM » |

|

@Valkpilot and @BaggerJohn... you guys really got me thinking about the whole situation and its very possible that all I really needed to do in a sense is get a bigger hammer... I bought a 3 lb dead blow to use to help get it all together. - I was kinda spoiled by the first time I assembled it, it was soooo easy. I had that in mind with the new rings and it was much more stubborn... My habit as a wrencher is I'm very much a finesse guy, and thinking with new orings being more difficult to get together was somewhat an issue, but its very possible per you guys that it was not........ maybe I just needed the bigger hammer. That all said, I am really satisfied with all the work adding the chamfer lead on the front of the drive flange was a good idea.. If I would ever need to buy a new one for any reason, I would do it again. Giving a lead in for the 3rd oring made a big difference in ease of assembly. That sharp edge on the front of the flange does catch on the ring... -- Also, I'm glad I bought the oring holder to play with, it helped understand things about the assembly. So, getting down to working it...... (I was planning to use the Redeye orings, so when I got them in the mail, I put them in a safe place so I could find them.... but of course, when I needed them, I couldnt find them  ) - Still dont know where they are...  Flange pushed on with thumb power, was easy! 3rd oring in place, Fat oring in place.  Made a holding strap per ChrisJ CMA, made working with it easier   Really made an effort to get everything aligned up. I have an extra Honda axle and used it on the left side of the bike to get it all started. Also paid attention to not over grease things, but just enough..  Then got the Valk axle in and worked it across to then knock out the other axle.  So when it came down to it, I was able to pull it together with a knee on the pumpkin and grabbing the wheel to pull it together. (amen) It slipped together like a glove, easy...   Its on all the way..  Well, I've beat this to death....no more orings for breakfast for me...  There's still plenty of work to do..  .....Chances are there will be other stuff to beat to death on..  |

|

|

|

« Last Edit: September 01, 2019, 07:48:40 PM by mello dude »

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

|