|

yrunvs

|

|

« on: July 25, 2020, 06:13:06 PM » |

|

Well.... I was hesitant to start this project but this bike is new to me and I had to know what the splines and drive shaft looked like. I've seen threads of dusty innards and I needed to find out about my Valks innards. These bikes are big....everything is big and heavy. Long story short after much sweat i found all splines in perfect condition I cleaned and regreased. I Probably need the rubber damper and shock rubber spacers.

But......I am at an impasse.....reinstalling the rear wheel has become a problem. The rear wheel is heavy and I just cant seem to get the splines to mesh from the wheel to the pumpkin, I lift the wheel into a near position and try to push it together but the splines just dont seem to want to slip into position. What am I doing wrong? I have been close but the plastic guard doesnt nestle back into its beginning position. Any advice is appreciated. Tomorrow I go back at it again with renewed hopes.

The drive shaft was a bitch to get back in but a search here solved that immediately. You put the wheel flange onto the pumpkin which allows you to rotate/wiggle the drive shaft which then drops right into place.

|

|

|

|

« Last Edit: July 25, 2020, 06:23:17 PM by yrunvs »

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Jess from VA

|

|

« Reply #1 on: July 25, 2020, 06:48:12 PM » |

|

The easiest trick to get things back together, is to run the axle through the pumpkin and wheel, but leave the brake caliper and spacer off the other side (do not forget the internal wheel spacer tube or thrust washer). With the axle all the way through, the wheel is now straight and level, and you don't have to ruin your back trying to hold it up, and you should be able to mate things together properly. Also, some new Orings are a bit fatter than others, and those have caused difficulty in the mating process. With everything mated properly, then pull the axle back out just enough to add the caliper and spacer.

Also there is a groove in the metal and on reassembly it seems intuitive that the plastic guard should cover the groove.... but it doesn't. This is where before (and after) pictures can come in handy, though I've never done it.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #2 on: July 25, 2020, 06:58:10 PM » |

|

I know the thrust washer is in place and lubed but the internal spacer??? Is that the one in the pumpkin?

|

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Chrisj CMA

|

|

« Reply #3 on: July 25, 2020, 06:59:34 PM » |

|

You probably had it there. Many people thought that line around the hub of the wheel should get closer to the dust guard. It doesn’t get to the dust guard if all the pieces go in it’s in. The most important thing is that the right side shock is off and four nuts to the pumpkin are loose when you torque the axle nut. Then immediately torque those four nuts to lock in the alignment. Then attach the shock to the pumpkin.

|

|

|

|

« Last Edit: July 25, 2020, 07:12:41 PM by Chrisj CMA »

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #4 on: July 25, 2020, 07:02:45 PM » |

|

I know the thrust washer is in place and lubed but the internal spacer??? Is that the one in the pumpkin?

There is s removable internal spacer in the pumpkin. You cannot properly torque the axle without that spacer in there |

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #5 on: July 25, 2020, 07:06:23 PM » |

|

Oh Gawd, I think its in there what would be the indication it isnt?

|

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Chrisj CMA

|

|

« Reply #6 on: July 25, 2020, 07:11:07 PM » |

|

Oh Gawd, I think its in there what would be the indication it isnt?

Continue on with the assembly |

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #7 on: July 25, 2020, 07:25:10 PM » |

|

Thanks Chris and Jess for the advice.

|

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

yrunvs

|

|

« Reply #8 on: July 25, 2020, 08:03:49 PM » |

|

Oh Gawd, I think its in there what would be the indication it isnt?

Continue on with the assembly I had the axle through to the brake side but didnt have enough space to get the brake caliper on.....was that because the the splines were not matched up? |

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

bikerboy1951

|

|

« Reply #9 on: July 25, 2020, 08:14:46 PM » |

|

For me, it seems to help to have the bike in gear while installing the wheel.

Brad

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Ramie

|

|

« Reply #10 on: July 25, 2020, 11:18:43 PM » |

|

I've set the rear wheel on a floor jack and lifted it into place. Of course your bike has to high enough for that to work.

|

|

|

|

|

Logged

Logged

|

“I am not a courageous person by nature. I have simply discovered that, at certain key moments in this life, you must find courage in yourself, in order to move forward and live. It is like a muscle and it must be exercised, first a little, and then more and more. A deep breath and a leap.”

|

|

|

hubcapsc

Member

Posts: 16804

upstate

South Carolina

|

|

« Reply #11 on: July 26, 2020, 03:33:34 AM » |

|

Howdy yrunvs... You're running into problems that are "normal", especially the first time or so that you have the wheel off... If you were to leave the spacer out, you'd see it around somewhere, it is four or five inches long and big around as a large socket. And your wheel will barely turn when you get the bike back together :-) ... I work alone, so I can relate to needing four arms when doing this job... Getting the axle through the caliper plate and moving the swingarm around while you're trying to get the drive shaft to plug into the u-joint will be easy one time and take four tries the next time... You'll get into some kind of groove that works for you after you've done it a couple of times...    Jeff from Florida has a tutorial in Shoptalk... The manual is online at: http://valkyrienorway.com/download.htmlDaniel Meyer does it to his own bike in a tech session each year at InZane... -Mike |

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #12 on: July 26, 2020, 05:11:00 AM » |

|

Oh Gawd, I think its in there what would be the indication it isnt?

Continue on with the assembly I had the axle through to the brake side but didnt have enough space to get the brake caliper on.....was that because the the splines were not matched up? Maybe not. It’s a tight squeeze. Sometimes I have to take advantage of the fact there is a little wiggle room for the wheel before the axle is though. Get a little angle so you can wedge in a corner of the caliper plate then kind of shoe horn it in there |

|

|

|

|

Logged

Logged

|

|

|

|

|

Pluggy

|

|

« Reply #13 on: July 26, 2020, 05:58:38 AM » |

|

That large O-ring on the splines flange is about 1/10 inch wide. You should feel it compress and go into place when the wheel is fully inserted in the final drive. You will feel a little "bump" when it happens. If it looks like you need an extra tenth inch to fit it all together, the wheel may not be all the way in.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #14 on: July 26, 2020, 08:26:31 AM » |

|

The drive shaft was a bitch to get back in but a search here solved that immediately. You put the wheel flange onto the pumpkin which allows you to rotate/wiggle the drive shaft which then drops right into place.

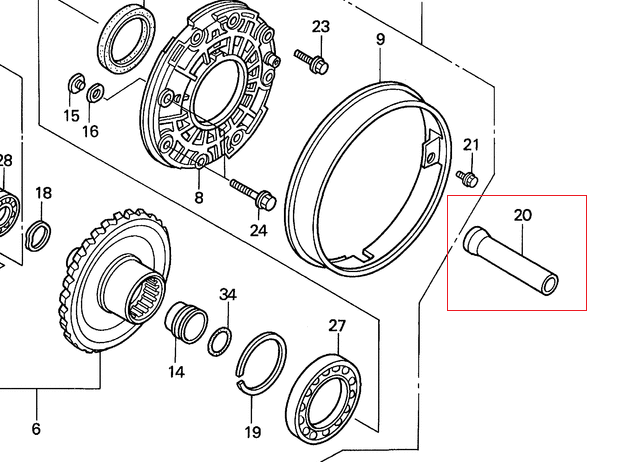

You probably did but those 4 bolts that connect the swingarm to the pumpkin are supposed to be tightened *last* after torquing down the rear axle. That is, if you tightened the 4 bolts while trying to get the drive shaft aligned, you suppose to loosen them so they can be tightened down after the rear axle is torqued down, in the proper order of things. I always asked which way should the spacer point? People state "you can't get it wrong." And there's something on the way the spacer faces in the schematic is the wrong way. It's an error. If you took your spacer out, did you install it facing the correct direction?  This is as far as my dust shield goes on the rear wheel.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

yrunvs

|

|

« Reply #15 on: July 26, 2020, 12:19:40 PM » |

|

Eureka! success!

I put wooden blocks under the tire and was able to get the wheel in the pumpkin but not far enough to get the brake bracket back on so I put spacers (small sockets the long way) where the brake bracket goes and tightened down the axle nut which drew the hub and the pumpkin together then I took the axle nut off and had enough room to slip the brake bracket on and was able to button it all up.

The thrush washer is in place and all splines are greased.

Nut tightening to spec sequence.......brake bracket then axle nut then pumpkin bolts.

All spacers in place and the wheel spins smoothly and quietly.

Test ride seemed fine.

Thanks to all for the advice which was very helpful.

|

|

|

|

« Last Edit: July 26, 2020, 12:23:40 PM by yrunvs »

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Jess from VA

|

|

« Reply #16 on: July 26, 2020, 01:19:15 PM » |

|

Yaay team.  It definitely makes you wish you had a single sided swing arm of the more recent persuasion. The first time I did this, I discovered several little issues that I had to address along the way. The bike suddenly tried to fall forward off the jack when I dropped the wheel and pumpkin, I had a bad Ujoint, I had rubbed (and exposed) wiring under the fender, I had rust and corrosion on the inside of the two fender half junction, and I needed to do the nut cage mod for my new car tire..... and I had a sore back, a mashed thumb, a gash on my head, and had nearly exhausted all my fowl language. It gets easier with repetition, but it never seems to get more fun. |

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #17 on: July 26, 2020, 02:05:09 PM » |

|

It definitely was a chore. But you do find out a lot about your bike along the way. The first time was a bit scary. Because of Jess's bike falling forward story I did put a jack under each front roll bar. I did the harbor freight main jack and a jack under the swing arm and I removed the bottom rear fender and both rear shocks and jacked the SA up and down. I found that I should probably get a new rubber damper because I did have some rubber dust. The bushings in the shocks looked like they needed replacement. After getting it all back together the hand brake would not light up the back brake light so I fiddled around and all of a sudden it works now.

I've got 2 small cuts on my head and an aching back I dont plan to do the drive shaft again until at least next year.

The first time doing this job was intimidating and hard that's for sure.

|

|

|

|

« Last Edit: July 26, 2020, 02:06:40 PM by yrunvs »

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

yrunvs

|

|

« Reply #18 on: July 26, 2020, 02:10:53 PM » |

|

One last question just to double check......If I got it all back together with no extra parts and the wheel spins smoothly and quietly and I torqued down the drive shaft last and the brakes work fine and the thrush washer is in the correct place and the test ride seemed normal.... is it fair to say all is well??

|

|

|

|

« Last Edit: July 26, 2020, 02:14:41 PM by yrunvs »

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

The emperor has no clothes

|

|

« Reply #19 on: July 26, 2020, 02:29:39 PM » |

|

One last question just to double check......If I got it all back together with no extra parts and the wheel spins smoothly and quietly and I torqued down the drive shaft last and the brakes work fine and the thrush washer is in the correct place and the test ride seemed normal.... is it fair to say all is well??

Sounds like you did it correct to me. I would definitely go with new shock bushings. Handling will improve. The VTX ones are better. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Jess from VA

|

|

« Reply #20 on: July 26, 2020, 02:41:29 PM » |

|

is it fair to say all is well??

Sure, I think so.

The other thing that can indicate your rubber dampers are failing is.... the bike is a torquey beast, but if you blip (not hammer) the throttle modestly in 1st or 2d gears (in a straight line), you can feel more than normal twitchy slop. If it's there, go a bit easier on it in power takeoffs.

It's good to plan ahead and order and have these things on hand, so if you have to get in there sooner than planned, everything's ready to go.

Did you change your 75/80-90 synthetic gear oil goop? It can be done on the bike, but it's easier when off. Do not twist off the chrome pumpkin vent cap, it's not made to come off (staked).

Also, it's not uncommon to get some spline grease throw up/out around the rear end and on the wheel the first couple rides after lube service. Esp if you overdo the grease like I do.

The other thing that is a real good idea is to start a log book. Write down the month and year and mileage, and what you did and what parts you used (cars and trucks too). I have a pretty good memory, but it's always good to be able to check your book next year, and know for sure.

|

|

|

|

« Last Edit: July 26, 2020, 02:53:59 PM by Jess from VA »

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #21 on: July 26, 2020, 03:06:45 PM » |

|

One last question just to double check......If I got it all back together with no extra parts and the wheel spins smoothly and quietly and I torqued down the drive shaft last and the brakes work fine and the thrush washer is in the correct place and the test ride seemed normal.... is it fair to say all is well??

Sounds like you did it correct to me. I would definitely go with new shock bushings. Handling will improve. The VTX ones are better. One point of clarification. The four nuts on the final drive should not be done LAST. They should be done immediately after torquing the axle nut and before attaching the right side shock. |

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #22 on: July 26, 2020, 05:21:55 PM » |

|

One last question just to double check......If I got it all back together with no extra parts and the wheel spins smoothly and quietly and I torqued down the drive shaft last and the brakes work fine and the thrush washer is in the correct place and the test ride seemed normal.... is it fair to say all is well??

Sounds like you did it correct to me. I would definitely go with new shock bushings. Handling will improve. The VTX ones are better. One point of clarification. The four nuts on the final drive should not be done LAST. They should be done immediately after torquing the axle nut and before attaching the right side shock. Yes sir that's exactly what I did. Axle nut then four drive shaft nuts then I put the shocks on. One thing I found interesting is the little hole in the pumpkin drive shaft coupling. With all of the grease in there I dont see how that hole stays open to transmit any oil unless a very very light coating of grease is used on the splines. When I cleaned that area out the grease was packed down there and the hole was plugged. I cleared it out but I presume its already plugged. |

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

yrunvs

|

|

« Reply #23 on: July 26, 2020, 05:25:57 PM » |

|

is it fair to say all is well??

Sure, I think so.

The other thing that can indicate your rubber dampers are failing is.... the bike is a torquey beast, but if you blip (not hammer) the throttle modestly in 1st or 2d gears (in a straight line), you can feel more than normal twitchy slop. If it's there, go a bit easier on it in power takeoffs.

It's good to plan ahead and order and have these things on hand, so if you have to get in there sooner than planned, everything's ready to go.

Did you change your 75/80-90 synthetic gear oil goop? It can be done on the bike, but it's easier when off. Do not twist off the chrome pumpkin vent cap, it's not made to come off (staked).

Also, it's not uncommon to get some spline grease throw up/out around the rear end and on the wheel the first couple rides after lube service. Esp if you overdo the grease like I do.

The other thing that is a real good idea is to start a log book. Write down the month and year and mileage, and what you did and what parts you used (cars and trucks too). I have a pretty good memory, but it's always good to be able to check your book next year, and know for sure.

I've changed the gear oil twice since I picked up the bike a month ago so I didnt change it this time. I do keep a log of any work done its a good idea. |

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Chrisj CMA

|

|

« Reply #24 on: July 26, 2020, 05:45:06 PM » |

|

One last question just to double check......If I got it all back together with no extra parts and the wheel spins smoothly and quietly and I torqued down the drive shaft last and the brakes work fine and the thrush washer is in the correct place and the test ride seemed normal.... is it fair to say all is well??

Sounds like you did it correct to me. I would definitely go with new shock bushings. Handling will improve. The VTX ones are better. One point of clarification. The four nuts on the final drive should not be done LAST. They should be done immediately after torquing the axle nut and before attaching the right side shock. Yes sir that's exactly what I did. Axle nut then four drive shaft nuts then I put the shocks on. One thing I found interesting is the little hole in the pumpkin drive shaft coupling. With all of the grease in there I dont see how that hole stays open to transmit any oil unless a very very light coating of grease is used on the splines. When I cleaned that area out the grease was packed down there and the hole was plugged. I cleared it out but I presume its already plugged. Perfect. Just want to keep it clear for someone else reading this someday |

|

|

|

|

Logged

Logged

|

|

|

|

mello dude

Member

Posts: 998

Half genius, half dumazz whackjob foole

Dayton Ohio

|

|

« Reply #25 on: July 26, 2020, 10:46:54 PM » |

|

Fav synthetic 75 - 90w gear oil guys?

|

|

|

|

|

Logged

Logged

|

* There's someone in my head, but it's not me.......

* Mr. Murphy was an optimist....

* There's a very fine line between Insanity and Genius.....

* My get up and go, must have got up and went.....

|

|

|

|

Chrisj CMA

|

|

« Reply #26 on: July 27, 2020, 04:47:04 AM » |

|

Fav synthetic 75 - 90w gear oil guys?

Lucas. Whatever you choose. It has to be hypoid rated. Look for the word “hypoid” or GL-5 rating |

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #27 on: July 27, 2020, 01:42:53 PM » |

|

is it fair to say all is well??

Sure, I think so.

The other thing that can indicate your rubber dampers are failing is.... the bike is a torquey beast, but if you blip (not hammer) the throttle modestly in 1st or 2d gears (in a straight line), you can feel more than normal twitchy slop. If it's there, go a bit easier on it in power takeoffs.

It's good to plan ahead and order and have these things on hand, so if you have to get in there sooner than planned, everything's ready to go.

Did you change your 75/80-90 synthetic gear oil goop? It can be done on the bike, but it's easier when off. Do not twist off the chrome pumpkin vent cap, it's not made to come off (staked).

Also, it's not uncommon to get some spline grease throw up/out around the rear end and on the wheel the first couple rides after lube service. Esp if you overdo the grease like I do.

The other thing that is a real good idea is to start a log book. Write down the month and year and mileage, and what you did and what parts you used (cars and trucks too). I have a pretty good memory, but it's always good to be able to check your book next year, and know for sure.

So the rear wheel damper comes as a set of 5 and not as one unit? |

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Chrisj CMA

|

|

« Reply #28 on: July 27, 2020, 01:58:50 PM » |

|

is it fair to say all is well??

Sure, I think so.

The other thing that can indicate your rubber dampers are failing is.... the bike is a torquey beast, but if you blip (not hammer) the throttle modestly in 1st or 2d gears (in a straight line), you can feel more than normal twitchy slop. If it's there, go a bit easier on it in power takeoffs.

It's good to plan ahead and order and have these things on hand, so if you have to get in there sooner than planned, everything's ready to go.

Did you change your 75/80-90 synthetic gear oil goop? It can be done on the bike, but it's easier when off. Do not twist off the chrome pumpkin vent cap, it's not made to come off (staked).

Also, it's not uncommon to get some spline grease throw up/out around the rear end and on the wheel the first couple rides after lube service. Esp if you overdo the grease like I do.

The other thing that is a real good idea is to start a log book. Write down the month and year and mileage, and what you did and what parts you used (cars and trucks too). I have a pretty good memory, but it's always good to be able to check your book next year, and know for sure.

So the rear wheel damper comes as a set of 5 and not as one unit? Yes five pieces. No they don’t connect together as a unit they each have their own little pocket to rest in  |

|

|

|

« Last Edit: July 27, 2020, 02:33:53 PM by Chrisj CMA »

|

Logged

Logged

|

|

|

|

|

Jess from VA

|

|

« Reply #29 on: July 27, 2020, 02:38:08 PM » |

|

|

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #30 on: July 27, 2020, 04:41:49 PM » |

|

Thanks for that. I had an older Triumph and it had a one unit five sectioned damper. Partzilla seems to have some good pricing for oem parts. Damper, shock bushings and thrust washer are in the cart any other items I should consider? I'd like to find the air cut off tubes maybe an email to Redeye will do that.

|

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Chrisj CMA

|

|

« Reply #31 on: July 27, 2020, 04:48:22 PM » |

|

Thanks for that. I had an older Triumph and it had a one unit five sectioned damper. Partzilla seems to have some good pricing for oem parts. Damper, shock bushings and thrust washer are in the cart any other items I should consider? I'd like to find the air cut off tubes maybe an email to Redeye will do that.

If buying OEM shock bushings, word on the street is the VTX 1800 ones work in the Valkyrie and are better. You also might want to get a couple each of the three Orings for the rear wheel project |

|

|

|

|

Logged

Logged

|

|

|

|

|

yrunvs

|

|

« Reply #32 on: July 27, 2020, 04:56:37 PM » |

|

Thanks for that. I had an older Triumph and it had a one unit five sectioned damper. Partzilla seems to have some good pricing for oem parts. Damper, shock bushings and thrust washer are in the cart any other items I should consider? I'd like to find the air cut off tubes maybe an email to Redeye will do that.

If buying OEM shock bushings, word on the street is the VTX 1800 ones work in the Valkyrie and are better. You also might want to get a couple each of the three Orings for the rear wheel project Yup I've got these in the cart https://www.partzilla.com/product/honda/52489-HN0-671the other stuff is oem. I'll probably put in an order to Redeye for the o rings and some other carb items. Am seriously considering this https://jerseymcproducts.bigcartel.com/product/jersey-bracket as shifting these beasties seems to be a physical endeavor and I dont want to wear the shifter bracket and or seals out. |

|

|

|

« Last Edit: July 27, 2020, 05:08:44 PM by yrunvs »

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

|

|

yrunvs

|

|

« Reply #34 on: July 27, 2020, 06:06:46 PM » |

|

Will the Jersey Bracket help wear and tear on that seal.

|

|

|

|

|

Logged

Logged

|

I'm no gynecologist but hey I'll take a look!

|

|

|

|

Jess from VA

|

|

« Reply #35 on: July 27, 2020, 06:11:32 PM » |

|

Perhaps, but rubber always wears out eventually.

Mine leaked a few drops every few months, so it didn't worry me any.

|

|

|

|

|

Logged

Logged

|

|

|

|

gordonv

Member

Posts: 5766

VRCC # 31419

Richmond BC

|

|

« Reply #36 on: July 27, 2020, 06:54:08 PM » |

|

Chrisj, is that your rim? An air pressure indicator? FYI I bought a set of them, 32 psi, had the one the bike for a year. I took them off to add dyna beads, checked my tire pressure, and one was 15 psi and the other was 20 psi. Both of the indicatiors where showing green for good pressure. Threw them away and went to a TPMS for $65 instead. After 2 blown rear tires, with the wife on the bike with me each time, I wanted a more reliable indicator of my tire pressure. |

|

|

|

|

Logged

Logged

|

1999 Black with custom paint IS   |

|

|

|

CoreyP

|

|

« Reply #37 on: July 27, 2020, 07:47:57 PM » |

|

Question?

How often should you replace wheel dampers? Mine looked fine when I took the wheel off, no cracking, etc. I'm just wonder if like all rubber pieces the performance drops with time or is it something you don't worry about until they fail?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #38 on: July 27, 2020, 08:14:38 PM » |

|

You can shim them instead.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #39 on: July 27, 2020, 08:59:33 PM » |

|

Will the Jersey Bracket help wear and tear on that seal.

most definitely |

|

|

|

|

Logged

Logged

|

|

|

|

|