|

99ISrdr

|

|

« on: November 04, 2020, 08:26:04 PM » |

|

I've got a 99 IS and the dealer rebuilt the carbs and checked the belts, said they looked like new but did tighten them. Well...the bike's running great, but after about 100 miles in I started noticing a soft squeak under the belt cover. I took the bike in to get a front tire installed and they checked the belt tensions and said they were fine. From what I've read on here it's pretty common for them to get noisy if they're the least bit tight, sometimes even on the tight end of spec. When I told the service manager I'd probably try to adjust them if the squeak continues....as he was walking off he said... good luck with cover. I don't get too mechanical except to change the oil, gap and install plugs etc...don't get involved with timing belts and such, but having read the shop manual a couple times it doesn't seem like a big deal, as long as I don't move the cam pulley marks off the cc marks. So my questions are...

1) Is there anything I need to be aware of when taking the cover off? I know it helps to warm it up first and I need to put a thread sealer on that one bolt, but he caught me off guard so I'm just making sure I'm not missing something that might be a royal PITA. Don't want to bust any of those bolts.

2) Anyone not using a locking agent on the tensioner bolts. I'd prefer not to if I don't have to.

Thanks in advance for any info.

Greg

|

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

|

RonW

|

|

« Reply #1 on: November 04, 2020, 09:38:42 PM » |

|

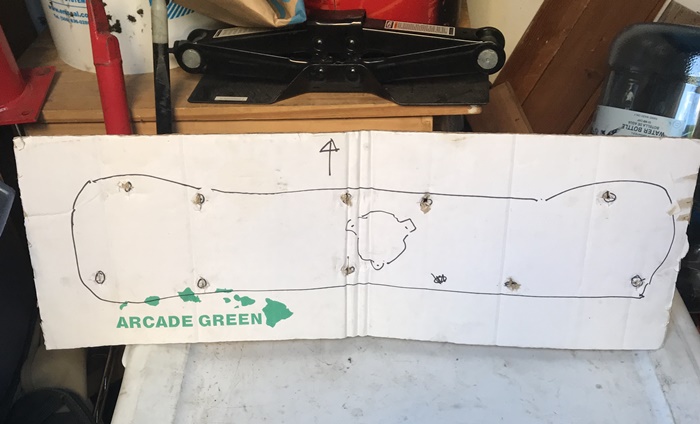

Many owners let the spring set the belt tension which seems scary but apparently the method is sound (somebody will chime in, elaborate). I would get a piece of cardboard the same dimension as the timing belt cover and stick the removed bolts in the cardboard in the same orientation since the bolts are different lengths.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

Bagger John - #3785

|

|

« Reply #2 on: November 05, 2020, 06:57:20 AM » |

|

I did the belts on my '99 Tourer a few thousand miles ago, and set the tension by the book.

Last season I noticed a bit of a squeak if I rolled the throttle on in 4th or 5th with the motor below 2500RPM. This season, all gone. Could be the belts wearing in. Of course, I bought new tensioners just in case...

|

|

|

|

|

Logged

Logged

|

|

|

|

|

jnicks01

|

|

« Reply #3 on: November 05, 2020, 08:09:46 AM » |

|

Many owners let the spring set the belt tension which seems scary but apparently the method is sound (somebody will chime in, elaborate). I would get a piece of cardboard the same dimension as the timing belt cover and stick the removed bolts in the cardboard in the same orientation since the bolts are different lengths.

That was my method. 5,000 miles later, no issues or noises. |

|

|

|

|

Logged

Logged

|

I want to scoop out your brains and eat your knowledge.  |

|

|

|

MotoBob

|

|

« Reply #4 on: November 05, 2020, 10:44:48 AM » |

|

1) Is there anything I need to be aware of when taking the cover off? I know it helps to warm it up first and I need to put a thread sealer on that one bolt, but he caught me off guard so I'm just making sure I'm not missing something that might be a royal PITA. Don't want to bust any of those bolts.

2) Anyone not using a locking agent on the tensioner bolts. I'd prefer not to if I don't have to. I just pulled my timing belt cover off my new/old 2000. And apparently the previous owner when attempting to pull the bolt with the thread sealer on it destroyed the Allen inset. As it turned out I had to use an easy out to pull it. I don't know what brand of sealer was initially used but it still required a considerable amount of leverage to remove it. On my previous Valk (150K/miles ) I never used sealer on the cover's bolt/bolts. And what's the point anyhow. You'd have to lose all the others before the cover came off. Just make sure they're all good and snug, check them periodically. I did use a single drop of blue on my tensioners' bolts though. |

|

|

|

« Last Edit: November 05, 2020, 10:53:38 AM by MotoBob »

|

Logged

Logged

|

|

|

|

|

SCain

|

|

« Reply #5 on: November 05, 2020, 12:00:01 PM » |

|

Only one bolt requires a sealant, that bolt is through to an oil passage. I believe it is the upper left second one in from the outer edge, check the book.

|

|

|

|

|

Logged

Logged

|

Steve  |

|

|

|

99ISrdr

|

|

« Reply #6 on: November 05, 2020, 05:18:31 PM » |

|

I appreciate the info. Great idea using the cardboard cover for the bolts.Hopefully the shop didn't apply loctite to the one cover bolt. Still wondering if anyone has tightened the tensioner bolt(s) without using a locking agent.

|

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

|

Chrisj CMA

|

|

« Reply #7 on: November 05, 2020, 05:44:44 PM » |

|

I appreciate the info. Great idea using the cardboard cover for the bolts.Hopefully the shop didn't apply loctite to the one cover bolt. Still wondering if anyone has tightened the tensioner bolt(s) without using a locking agent.

Almost 19 years and over 170,000 miles changed belts twice never used locking agents |

|

|

|

|

Logged

Logged

|

|

|

|

|

98valk

|

|

« Reply #8 on: November 05, 2020, 05:48:34 PM » |

|

follow the tech manual.

the pulley can have grease added to them. the back of the bracket has holes aligned with the seal. insert a needle tip and one pump of grease. there are many sites showing how to grease a sealed bearing.

|

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

|

F6Dave

|

|

« Reply #9 on: November 05, 2020, 05:59:18 PM » |

|

Warm the engine up before trying to loosen the bolts that hold the timing cover on. It will reduce the chance of breaking one when you remove them, especially the one with the sealant.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #10 on: November 05, 2020, 06:05:46 PM » |

|

"....as he was walking off he said... good luck with cover."  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

99ISrdr

|

|

« Reply #11 on: November 05, 2020, 09:21:40 PM » |

|

Lots of great info, much appreciated. Thanks guys.

|

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

John Schmidt

Member

Posts: 15347

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #12 on: November 05, 2020, 10:00:28 PM » |

|

Re. bolts in their proper place, keep in mind there are and always have been those that actually leave the front cover off. I've seen any number of old Wings running that way....rain or shine, and with tons of miles on them. Plus, I've seen a handful of Valks running the same way although I wouldn't do so.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

99ISrdr

|

|

« Reply #13 on: November 20, 2020, 08:46:45 AM » |

|

Well....finally getting around to adjusting the belt(s) tension. The right side is measuring 3/8"(9.5mm) the left is tight at 3/16"(4.7mm). I know specs read 5-7mm but I read here somewhere where someone runs them a little loose at 3/8". From what I've read, running them a little loose runs quiet and doesn't cause a problem vs tight. I'm thinking of keeping the right at 3/8" and setting the left at 3/8". Anyone else running a little loose at around 3/8? Any suggestions as to setting them to 3/8" or adjusting them both to around 7mm? I will try letting the spring adjust the left and see what that measures though.

|

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

|

98valk

|

|

« Reply #14 on: November 20, 2020, 09:03:19 AM » |

|

Well....finally getting around to adjusting the belt(s) tension. The right side is measuring 3/8"(9.5mm) the left is tight at 3/16"(4.7mm). I know specs read 5-7mm but I read here somewhere where someone runs them a little loose at 3/8". From what I've read, running them a little loose runs quiet and doesn't cause a problem vs tight. I'm thinking of keeping the right at 3/8" and setting the left at 3/8". Anyone else running a little loose at around 3/8? Any suggestions as to setting them to 3/8" or adjusting them both to around 7mm? I will try letting the spring adjust the left and see what that measures though.

do what the tech manual states. The Honda engineers that designed and built the engine have it right and used the Gates design manual for belts. |

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

|

Ricky-D

|

|

« Reply #15 on: November 20, 2020, 09:39:27 AM » |

|

When adjusting the cam belts

You should turn the crankshaft so as to take up any slack on the tension side of the belt.

And then let the spring move the idler pulley to take up the slack on the slack side of the belt.

There is no need to help the spring and doing so could have unintended consequences.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|

99ISrdr

|

|

« Reply #16 on: November 20, 2020, 05:45:21 PM » |

|

When adjusting the cam belts

You should turn the crankshaft so as to take up any slack on the tension side of the belt.

And then let the spring move the idler pulley to take up the slack on the slack side of the belt.

There is no need to help the spring and doing so could have unintended consequences.

***

When I turned the crankshaft to remove the slack, this time I got about 1/4"(6.3mm) on both, therefore didn't adjust anything. I'm thinking now it might be a tensioner bearing. Also, it doesn't start making noise until it's been running a few miles. Was hoping a little adjusting would take care of it. Oh well... |

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

|

98valk

|

|

« Reply #17 on: November 20, 2020, 06:08:26 PM » |

|

When adjusting the cam belts

You should turn the crankshaft so as to take up any slack on the tension side of the belt.

And then let the spring move the idler pulley to take up the slack on the slack side of the belt.

There is no need to help the spring and doing so could have unintended consequences.

***

When I turned the crankshaft to remove the slack, this time I got about 1/4"(6.3mm) on both, therefore didn't adjust anything. I'm thinking now it might be a tensioner bearing. Also, it doesn't start making noise until it's been running a few miles. Was hoping a little adjusting would take care of it. Oh well... how many miles on pulleys? there are holes on the back plate providing access with a grease needle fitting to add a little more additional grease pass the seal. |

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

|

99ISrdr

|

|

« Reply #18 on: November 20, 2020, 06:25:46 PM » |

|

When adjusting the cam belts

You should turn the crankshaft so as to take up any slack on the tension side of the belt.

And then let the spring move the idler pulley to take up the slack on the slack side of the belt.

There is no need to help the spring and doing so could have unintended consequences.

***

When I turned the crankshaft to remove the slack, this time I got about 1/4"(6.3mm) on both, therefore didn't adjust anything. I'm thinking now it might be a tensioner bearing. Also, it doesn't start making noise until it's been running a few miles. Was hoping a little adjusting would take care of it. Oh well... how many miles on pulleys? there are holes on the back plate providing access with a grease needle fitting to add a little more additional grease pass the seal. About 40,000. Just bought the bike a cpl months ago and pretty sure the po never changed them. Maybe a shot of grease might help. |

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

|

98valk

|

|

« Reply #19 on: November 20, 2020, 06:32:49 PM » |

|

When adjusting the cam belts

You should turn the crankshaft so as to take up any slack on the tension side of the belt.

And then let the spring move the idler pulley to take up the slack on the slack side of the belt.

There is no need to help the spring and doing so could have unintended consequences.

***

When I turned the crankshaft to remove the slack, this time I got about 1/4"(6.3mm) on both, therefore didn't adjust anything. I'm thinking now it might be a tensioner bearing. Also, it doesn't start making noise until it's been running a few miles. Was hoping a little adjusting would take care of it. Oh well... how many miles on pulleys? there are holes on the back plate providing access with a grease needle fitting to add a little more additional grease pass the seal. About 40,000. Just bought the bike a cpl months ago and pretty sure the po never changed them. low miles they should not be a problem. at 55k the pulleys were perfect on my bike. now at 52k miles the rear bearing on the alternator was not how it should be, so I replaced it with a better one from Napa. |

|

|

|

|

Logged

Logged

|

1998 Std/Tourer, 2007 DR200SE, 1981 CB900C 10speed

1973 Duster 340 4-speed rare A/C, 2001 F250 4x4 7.3L, 6sp

"Our Constitution was made only for a Moral and Religious people. It is wholly inadequate to the goverment of any other."

John Adams 10/11/1798

|

|

|

|

99ISrdr

|

|

« Reply #20 on: November 20, 2020, 08:08:51 PM » |

|

When adjusting the cam belts

You should turn the crankshaft so as to take up any slack on the tension side of the belt.

And then let the spring move the idler pulley to take up the slack on the slack side of the belt.

There is no need to help the spring and doing so could have unintended consequences.

***

When I turned the crankshaft to remove the slack, this time I got about 1/4"(6.3mm) on both, therefore didn't adjust anything. I'm thinking now it might be a tensioner bearing. Also, it doesn't start making noise until it's been running a few miles. Was hoping a little adjusting would take care of it. Oh well... how many miles on pulleys? there are holes on the back plate providing access with a grease needle fitting to add a little more additional grease pass the seal. About 40,000. Just bought the bike a cpl months ago and pretty sure the po never changed them. low miles they should not be a problem. at 55k the pulleys were perfect on my bike. now at 52k miles the rear bearing on the alternator was not how it should be, so I replaced it with a better one from Napa. I'm going to let the springs set the pulleys tomorrow. If it's still making noise I think I'm just going to get the gates belts and pulleys and do a rebuild and be done with it. The pulley rebuild looks easy enough and pretty reassuring. Just saw a great post with pics on it. |

|

|

|

|

Logged

Logged

|

99 Interstate

09 Kawasaki Concours 14

|

|

|

|