|

valk2128

|

|

« on: May 24, 2010, 02:25:26 PM » |

|

Took the front-end apart and removed the steering stem this past weekend.

The bearing races were indexed, so I might have found my wobble/vibration issue.

Today I took the steering stem to a local private Motor Cycle shop to get the lower bearing removed and the new bearing installed.

The guy pried the old bearing off .

He then put the steering stem in ice and heated the bearing on an electric heating plate to between 250 - 300 degrees.

The bearing dropped right on, he then sprayed it with something to cool down.

Would the heating of the bearing hurt the bearing, cause it to fail prematurely , or should it be okay??

Thanks

|

|

|

|

« Last Edit: May 24, 2010, 03:39:40 PM by valk2128 »

|

Logged

Logged

|

|

|

|

Daniel Meyer

Member

Posts: 5493

Author. Adventurer. Electrician.

The State of confusion.

|

|

« Reply #1 on: May 24, 2010, 02:44:01 PM » |

|

If it was to 300 degrees (and not higher...like glowing or something) it will be fine.

|

|

|

|

|

Logged

Logged

|

CUAgain, Daniel Meyer  |

|

|

|

valk2128

|

|

« Reply #2 on: May 24, 2010, 03:00:35 PM » |

|

It was not glowing, but it is a little discolored now.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Ricky-D

|

|

« Reply #3 on: May 24, 2010, 04:51:54 PM » |

|

It is the quick cooling that will affect the crystalline structure of the steel.

He shouldn't have done that. It was stupid!

See if some polishing compound will remove the discoloration.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|

RP#62

|

|

« Reply #4 on: May 24, 2010, 05:54:43 PM » |

|

If it changed color, it changed the temper. When you heat treat medium and high carbon steels, you heat them to a cherry red then quench. The steel is now at it hardest (and most brittle). To temper, or remove some of the hardness, you polish a portion of the surface then slowly heat it until it starts to change color. Once it gets to the color you're looking for, you quench it to halt the tempering process. Heated to a straw color removes the least amount of hardness. This is the temper that stone cutting tools are heated to. A peacock blue removes the most amount of hardness, but provides the most flexibility. This is what springs are usually heated to. If you go beyond peacock blue, you've removed all the hardness and have to start over. This is greatly simplified and gets complicated with alloy steels, but you get the idea.

-RP

|

|

|

|

|

Logged

Logged

|

|

|

|

|

valk2128

|

|

« Reply #5 on: May 24, 2010, 08:39:16 PM » |

|

The center of the bearing touching the center steering stem, shaft has a slight silver blueness to it, the tapered bearings and housing are just a little darker than normal with a slight browning.

So, should I get a new bearing and start over, or will this bearing be okay.

Thanks

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Blackduck

|

|

« Reply #6 on: May 25, 2010, 05:42:48 AM » |

|

+1 on Daniels view.

Heating bearings is a tried and true way to install without pressing.

I would not even try to guess how many I have installed by heating in far move demanding enviroments than steering head bearings.

The brown look may just be from the lube on the bearings.

Cheers Steve

|

|

|

|

|

Logged

Logged

|

2001 Standard, 78 Goldwing, VRCC 21411

|

|

|

|

RP#62

|

|

« Reply #7 on: May 25, 2010, 06:07:28 AM » |

|

If it truely was 300°, that shouldn't have been enough to change the temper, and I'd agree it probably just cooked the preservative oil. If it was a deep blue, though, I wouldn't use them.

-RP

|

|

|

|

|

Logged

Logged

|

|

|

|

Skinhead

Member

Posts: 8752

J. A. B. O. A.

Troy, MI

|

|

« Reply #8 on: May 25, 2010, 09:52:01 AM » |

|

It is the quick cooling that will affect the crystalline structure of the steel.

He shouldn't have done that. It was stupid!

See if some polishing compound will remove the discoloration.

***

As a metallurgical engineer, I can assure you that 300 degrees is not a high enough temperature to cause a phase change or affect the microstructure of the steel. There is also a time at temperature required for a transformation to take place. They will be fine, just be sure to pack them with grease. |

|

|

|

« Last Edit: May 25, 2010, 09:53:51 AM by Skinhead »

|

Logged

Logged

|

Troy, MI |

|

|

Daniel Meyer

Member

Posts: 5493

Author. Adventurer. Electrician.

The State of confusion.

|

|

« Reply #9 on: May 25, 2010, 03:48:29 PM » |

|

Yeah, I think they'd have to approach 700 F to start any kind of change in the state of the steel...that's glowing red temps there...

|

|

|

|

|

Logged

Logged

|

CUAgain, Daniel Meyer  |

|

|

|

Mr.BubblesVRCCDS0008

|

|

« Reply #10 on: May 25, 2010, 04:17:44 PM » |

|

Do it all the time at work.We have and old pizza oven (small one) heat bearing to 250-275 and tap into place with brass flatnose punch. We just allow it to cool by it's self. The shaft will start to pull the heat out of it on contact.  |

|

|

|

|

Logged

Logged

|

|

|

|

Skinhead

Member

Posts: 8752

J. A. B. O. A.

Troy, MI

|

|

« Reply #11 on: May 25, 2010, 04:23:24 PM » |

|

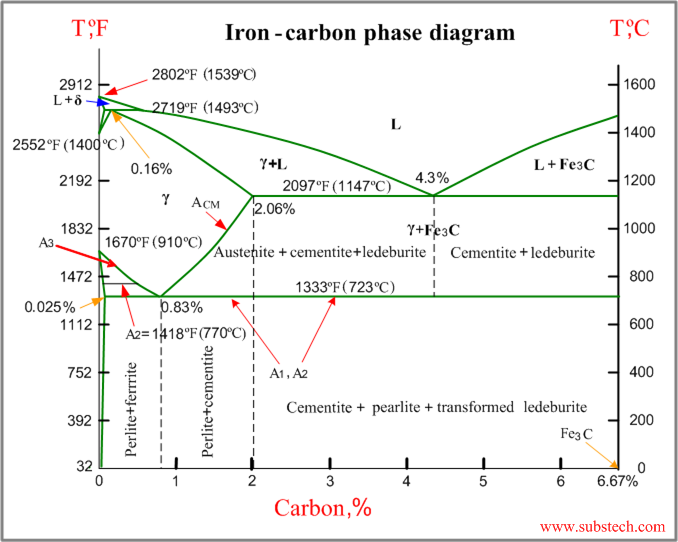

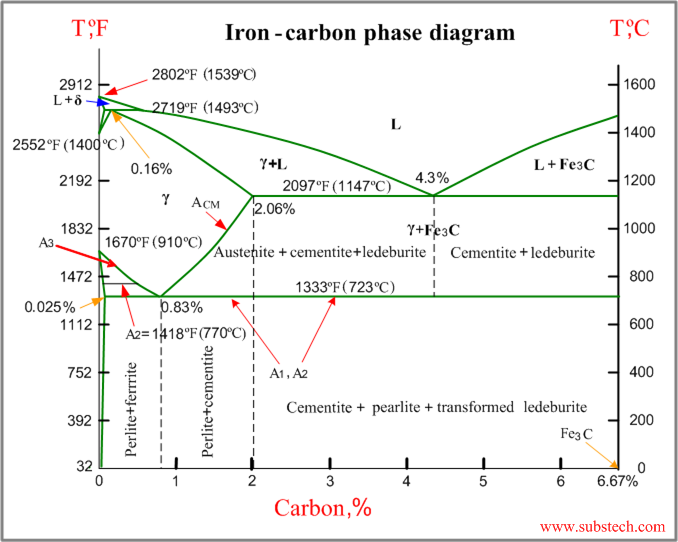

Check it out for yourself:  |

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

fudgie

Member

Posts: 10651

Better to be judged by 12, then carried by 6.

Huntington Indiana

|

|

« Reply #12 on: May 25, 2010, 04:28:46 PM » |

|

Check it out for yourself:  Oh this makes sence!  Just kidding, not sure how to read it.  |

|

|

|

|

Logged

Logged

|

Now you're in the world of the wolves... And we welcome all you sheep... VRCC-#7196 VRCCDS-#0175 DTR PGR |

|

|

Skinhead

Member

Posts: 8752

J. A. B. O. A.

Troy, MI

|

|

« Reply #13 on: May 25, 2010, 04:43:46 PM » |

|

It shows the different Phases or microstructures that will result in Iron and steel depending on carbon content and heat treatment. I went to the University of Pittsburgh to learn how to read it. That was over 30 years ago, so I'm not much better at reading it than you are anymore.

|

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|