|

YoungPUP

|

|

« on: March 18, 2012, 05:51:31 PM » |

|

In the process of hooking up the stop/tail/turn on my valk, I managed to break one of the hot terminals off in the socket. It was crimped on, and was wondering if there was a way to make/solder the original one back into place?

|

|

|

|

|

Logged

Logged

|

Yea though I ride through the valley of the Shadow of Death I shall fear no evil. For I ride the Baddest Mother F$#^er In that valley!

99 STD (Under construction)

|

|

|

|

3W-lonerider

|

|

« Reply #1 on: March 18, 2012, 05:53:23 PM » |

|

you might be better off going to a junk yard and getting a nub from an old tailight from a car.

or you can buy a trailer light at napa ot auto store cheap and just take the nub and wire from it.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

YoungPUP

|

|

« Reply #2 on: March 18, 2012, 05:58:01 PM » |

|

Thats on the back-up list, but soldering is on my Cheap-a$$ list...

|

|

|

|

|

Logged

Logged

|

Yea though I ride through the valley of the Shadow of Death I shall fear no evil. For I ride the Baddest Mother F$#^er In that valley!

99 STD (Under construction)

|

|

|

|

RonW

|

|

« Reply #3 on: March 18, 2012, 06:44:42 PM » |

|

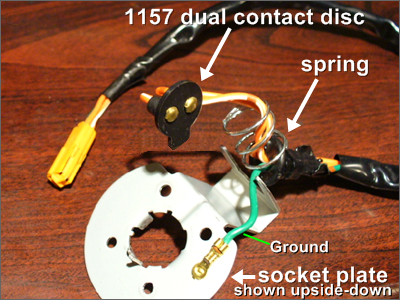

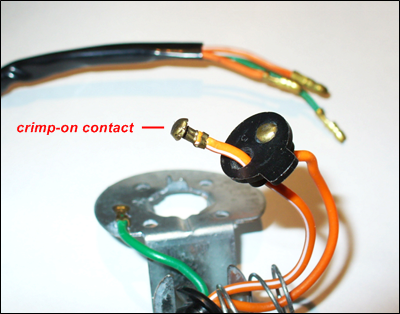

are those the type of turn signals that have 2-screws on the lens? The reason that I ask is that the single-screw lens (00'+ on Valks) have a different assembly inside the abs shells and I'm assuming the sockets are different too. Inside view of 2-screw turn signals here. Versus single-screw turn signals here. The socket knobs on a single-screw seems solder-able if not re-crimpable. If the 2-screw signals have the same 'contact disk' as a single-screw signal (pictured below), the knob probably can be resoldered back to the socket.    |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

YoungPUP

|

|

« Reply #4 on: March 18, 2012, 06:49:55 PM » |

|

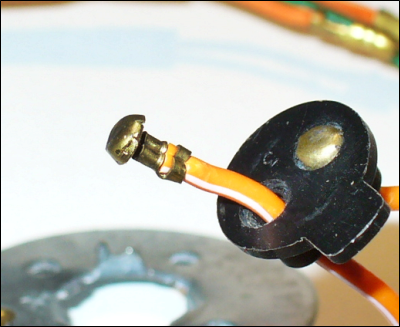

Newer style with the single screw and the crimp on type like in the bottom pic. Was looking at drilling a hole in the center of the head( just big enough for the wire and soldering it in place.)

|

|

|

|

|

Logged

Logged

|

Yea though I ride through the valley of the Shadow of Death I shall fear no evil. For I ride the Baddest Mother F$#^er In that valley!

99 STD (Under construction)

|

|

|

|

|

|

RonW

|

|

« Reply #6 on: March 19, 2012, 04:44:09 AM » |

|

oh, wow! Then you could use your stock 1156 rear signals and just rewire in 1157 sockets from Grote®.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

Blackduck

|

|

« Reply #7 on: March 19, 2012, 05:35:02 AM » |

|

If the piece is as in the other photos then it should be do-able, file off the folded over crimp until you can remove the old wire and insulation then just solder the wire back onto the place where the old wire was crimped.

Cheers Steve

|

|

|

|

|

Logged

Logged

|

2001 Standard, 78 Goldwing, VRCC 21411

|

|

|

R J

Member

Posts: 13380

DS-0009 ...... # 173

Des Moines, IA

|

|

« Reply #8 on: March 19, 2012, 10:03:45 AM » |

|

If I am reading your problem correctly. However let me ask a question.

Did the nubbon break off?

If so, go to Auto Zone, O'Reilly's or your favorite auto store and just buy the crimp on nubbon. Cut the old one off the wire, strip the wire about 1/2" put it on the nubbon and crimp it. Now solder that connection. PS: Make sure the wire is in the fiber disk where it belongs.

If the nubbon is still in full size, cut the wire up close to the nubbon, trim the wire, wind it up good and solder to the nubbon. Oh yes, be sure and have a little piece of shrink tube on the line also so as to keep it from shorting out on the other one.

Now, if I was doing it, I'd head over to my nearest salvage yard. I'd walk in, tell Rich what I need and that I have a pair of side cutters in my pocket. He'd say, you know the way around the yard, go get what ya need. I'd find a dual post taillight, turn signal, or what have ya. Take it off the car, pull the fiber disk and the wires up out of the light socket. When I got about 6" of wire, I'd cut it and go back to the office. Sometimes he charges me and other times he says I'll get ya next time.

Go back to the shop, pull the fiber disk and wires up out of the taillight. cut one 1, and cut the other one a couple of inches longer. Cut the new holder wires to match the ones on the vehicle. Put a couple of heat shrink tubes on the wires, twist the wires in line, make a connection about the same size as the wire, solder and heat shrink it. Duplicate the same on the other wire.

Your solder points should not be able to touch each other in case a heat shrink should come off, that is the reason for the offset cut.

Button it up and off down the road ya go.

Also, these little fiber disks and 2 wires can be bought in a Auto Parts store. I know O'Rielly has them.

|

|

|

|

« Last Edit: March 19, 2012, 10:06:12 AM by R J »

|

Logged

Logged

|

44 Harley ServiCar   |

|

|

|

YoungPUP

|

|

« Reply #9 on: March 19, 2012, 05:05:15 PM » |

|

Thanks all. Went and drilled a hole in the mushroom end of the terminal just big enough for the wire, and soldered it back in. I know it may seem like a silly thing, but have been trying very hard to save pennies so momma can be a stay at home momma for our twins. Every little bit counts. Thanks.

|

|

|

|

|

Logged

Logged

|

Yea though I ride through the valley of the Shadow of Death I shall fear no evil. For I ride the Baddest Mother F$#^er In that valley!

99 STD (Under construction)

|

|

|

|