|

jimmytee

|

|

« on: April 11, 2013, 06:49:19 PM » |

|

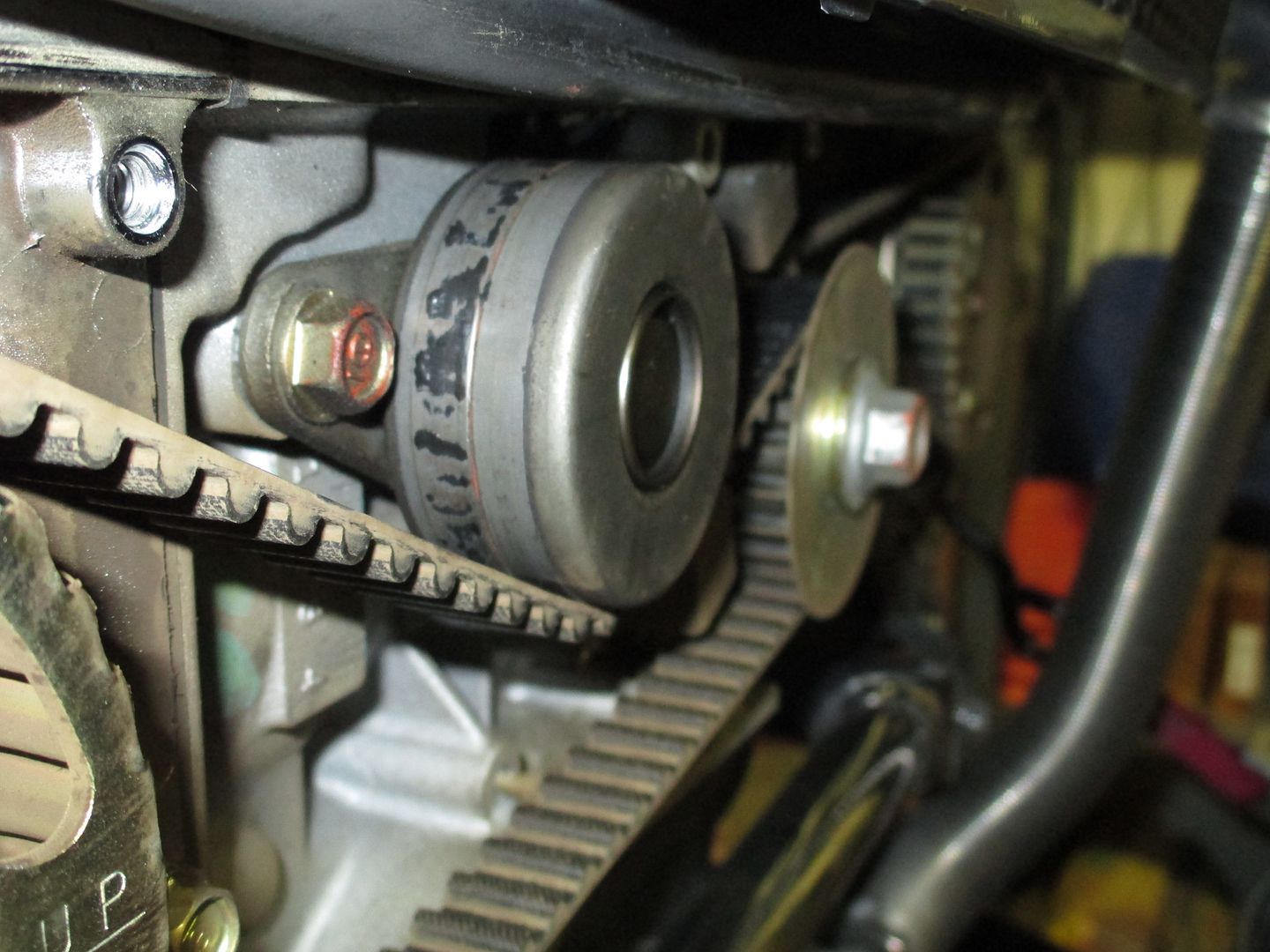

Well my timing belts didn't look bad at 69,000 miles, but because their 13 years old I decided it was cheap insurance. One of my tensioner pulleys also gave me some concern. No noticeable noise when running, but when I grasped the pulley firmly I could feel a very subtle amount of play. Once I had removed the tensioner, if you gave it a spin and listened very closely up to your ear, you could hear the roughness as it spun down. The other tensioner sounded smooth. I replaced both. Taking some advice and after getting some info, thanks Brian, I ordered the Gates T275 belts and the GatesT42015 tensioner pulleys. There are several methods to choose from when attaching the gates pulleys to the old tensioner mounting plates. I ended up, after returning from Fastenal with several options, using my own version of the common methods.    I used a 3/8" stainless flush mount allen head bolt. |

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

BonS

|

|

« Reply #1 on: April 11, 2013, 08:53:24 PM » |

|

I like what I see. That 3/8" stainless flush mount allen head bolt is perfect! My closest Fastenal Google's to a mobile home park; not good. I wonder if I can hope to find this at my local hardware store?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

jimmytee

|

|

« Reply #2 on: April 12, 2013, 04:04:19 AM » |

|

I suppose it would depend on your hardware store. I came home with grade 5 and grade 8 options plus a couple of stainless options. I wasn't sure which I was going to use. Didn't want to get home and into it and think "I should've got this or that". The bolt or screw I used is a 3/8" -16 x 1.5" Stainless Steal Flat Socket Cap Screw. That is how it's described on the invoice.

|

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

|

|

Westsider

|

|

« Reply #4 on: April 12, 2013, 08:47:01 AM » |

|

|

|

|

|

|

Logged

Logged

|

we'll be there when we get there - Valkless,, on lookout....

|

|

|

|

jimmytee

|

|

« Reply #5 on: April 12, 2013, 10:19:00 AM » |

|

Nice job!

Thanks, there is a PDF file available that describes these options. I had first went to an auto parts store seeking a couple of wheel studs and was told I'd have to order the ones I asked about. So I boogied on down to Fastenal before they closed,knowing that finding grade 5 or 8 and even some stainless would be limited at places like Lowes. It's worth mentioning that I was between using a 7/16" hex head grade 8 bolt and the one I chose. The 7/16" choice would work, there is plenty of room behind the plate for the head. It's not as if having something flush or near flush is required. The 7/16" option would have require drilling out the mounting hole in the gates bearing. You could do the same with a 3/8" hex head bolt. The tapered cone of the flat top screw I used just seemed like it was made for it. It went together very nicely. I used a lock washer and blue lock- tite then torqued the nut to 35 ft lbs. I believe my total outlay in $ was around $65 for everything give or take a dollar or two. The oem tensioner pulleys will set you back that for one.  |

|

|

|

« Last Edit: April 12, 2013, 10:23:18 AM by jimmytee »

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

NEHI

|

|

« Reply #6 on: April 12, 2013, 01:33:05 PM » |

|

It probably wouldn't be a problem with this application, but most stanless fasteners are about a grade 2. I would have gone for a grade 5. Very nice job though!

|

|

|

|

|

Logged

Logged

|

|

|

|

|

jimmytee

|

|

« Reply #7 on: April 12, 2013, 07:20:30 PM » |

|

It probably wouldn't be a problem with this application, but most stanless fasteners are about a grade 2. I would have gone for a grade 5. Very nice job though!

From what I've read by downloading a couple of PDF files, I believe you are right about that. There is a lot of misunderstanding out there about stainless bolts. I had never really gave them much thought as far as strength until it was one of the preferred materials in a pdf concerning the pulley modification. It spoke of stainless as if it were a stronger bolt. Having read a few charts with the psi ratings and maximum torque ratings I've come to the conclusion that while the stainless might be fine , I believe I've over torqued them and thereby have possibly weakened the bolts.  So any input would be nice, but I might go ahead and pull the tensioners and swap out the mounting bolt for the 7/16" grade 8 bolts I have.

|

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

pancho

|

|

« Reply #8 on: April 12, 2013, 08:22:29 PM » |

|

If they didn't feel like they were stretching as you torqued them,, you are probably fine,,, there is not a whole bunch of side pressure from the belts. Still, 35lbs was a bit much for that fastener.

|

|

|

|

|

Logged

Logged

|

The most expensive things you will purchase, are those things you would not have needed if you had listened and obeyed.

|

|

|

|

jimmytee

|

|

« Reply #9 on: April 13, 2013, 02:39:27 AM » |

|

I didn't notice any stretching. It felt solid, but I've seen on a chart the maximum suggested torque for stainless 18-8 / 304 , 3/8"dia-16 tpi is 259 inch lbs. I applied 35 ft. Lbs. Should've only used like 19 or 20.  . So I guess if I want peace at this point, I'm pulling the tensioners and replacing the bolt. |

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

James III

|

|

« Reply #10 on: April 13, 2013, 03:20:48 AM » |

|

Good writeup Jimmytee! Looks like you did your homework. I've been pushing a pdf of a couple of tensioner options across my desk; your route looks much better. The Honda tensioners do have a gold price tag on them.

|

|

|

|

|

Logged

Logged

|

James

|

|

|

|

pancho

|

|

« Reply #11 on: April 13, 2013, 07:34:28 AM » |

|

Im with you,,, that way you will never need to think about them again.

|

|

|

|

|

Logged

Logged

|

The most expensive things you will purchase, are those things you would not have needed if you had listened and obeyed.

|

|

|

|

jimmytee

|

|

« Reply #12 on: April 13, 2013, 08:06:03 AM » |

|

well did it. I ended up replacing the nice, like they're made for it, flat top socket screws for a set of 3/8" grade 8 hex head bolts. If fastenal was open today, I would've simply gone and got two more of the flat top screws, and not over torqued them. They probably would've been fine, but I would always wonder.  I wanna ride tomorrow, so I swapped them..

|

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

Brian

|

|

« Reply #13 on: April 14, 2013, 05:18:09 AM » |

|

Jimmy,

I am glad you had a good result with the info I sent ya. Was the $65 dollars the total including new belts or just for the rebuilt tensioner? With the pulley only costing around $17 that was expensive stainless steel hardware if you did. I tried stainless steel nuts and bolts for my windshield and had trouble with the threads stripping so I stayed with the black steel for this application and did not over tighten it.

Now you see why I went the flat head route. My hardware store bolt didn't fit that flush. Did you change the countersink on the mounting plate to match the bolt to get that fit? I wasn't concerned about that as I figured I only needed it to keep the bolt centered in the hole.

Awesome job and pictures Jimmy. Maybe we can get others to share their method if they do this easy rebuild.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

jimmytee

|

|

« Reply #14 on: April 14, 2013, 06:31:27 AM » |

|

The flat head bolts fit near perfectly. I, however decided that I over torqued them, and so I didn't have to worry, replaced them with 3/8" grade 8 hex head bolts. Not the perfect fit like the flat screws, but Fastenal not open on the weekends  It worked out though. The $65 is total for belts tensioners and hardware. $70 or so if you count the extra harware I also bought to be prepared for said eventualities.  |

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

Big Tom 10628

|

|

« Reply #15 on: May 15, 2015, 06:13:10 AM » |

|

Question on this old thread as I am getting ready to do this job. Does the Old Stud pop out or is drilling necessary?

|

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

Big Tom 10628

|

|

« Reply #16 on: May 15, 2015, 11:16:24 AM » |

|

OK I'll answer my own question. What size drill Bit should I use?

|

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

Bambam650

|

|

« Reply #17 on: May 15, 2015, 11:22:28 AM » |

|

|

|

|

|

|

Logged

Logged

|

1997 Standard (Black) original owner, bought new in August 1996

|

|

|

|

Big Tom 10628

|

|

« Reply #18 on: May 15, 2015, 12:09:34 PM » |

|

Thank you... I found this when I opened the bike up   |

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

Pappy!

|

|

« Reply #19 on: May 15, 2015, 04:46:39 PM » |

|

A rule of thumb on torques for common SAE sizes is:

1/4" - 5-7ft. lbs

5/16" - 10-12ft. lbs.

3/8" - 18-20ft.lbs.

Unless otherwise written these are good "go to" values.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Big Tom 10628

|

|

« Reply #20 on: May 15, 2015, 06:08:25 PM » |

|

Here's the culprit. Pulleys were slinging grease...  |

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

$ Ball

|

|

« Reply #21 on: May 15, 2015, 07:06:19 PM » |

|

Where was the grease coming from

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Bighead

|

|

« Reply #22 on: May 15, 2015, 07:28:26 PM » |

|

I would say from the bearing.

|

|

|

|

|

Logged

Logged

|

1997 Bumble Bee

1999 Interstate (sold)

2016 Wing

|

|

|

|

Big Tom 10628

|

|

« Reply #23 on: May 15, 2015, 08:28:27 PM » |

|

Where was the grease coming from

Grease was coming from the bearing. |

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

jimmytee

|

|

« Reply #24 on: May 16, 2015, 04:07:10 AM » |

|

Have had no issues for 2 years and approx 8-9 K miles, not that I expected to have. Just chiming in.  |

|

|

|

|

Logged

Logged

|

"Go sell crazy somewhere else,we're all stocked up"

|

|

|

|

Brian

|

|

« Reply #25 on: May 16, 2015, 05:22:19 AM » |

|

My rebuild using the gates pulley is still working just fine. Remember these are only applying little pressure on the belt to keep the slack to a minimum so heavy tightening of the bolt and nut is not necessary. If I were to do it again I think I would go with nylon locking nut.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Big Tom 10628

|

|

« Reply #26 on: May 16, 2015, 06:48:16 AM » |

|

My rebuild using the gates pulley is still working just fine. Remember these are only applying little pressure on the belt to keep the slack to a minimum so heavy tightening of the bolt and nut is not necessary. If I were to do it again I think I would go with nylon locking nut.

Torque value required for the tensioner mounting bolts is 19 Ft. Lbs. |

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

Brian

|

|

« Reply #27 on: May 17, 2015, 04:27:21 AM » |

|

I like what I see. That 3/8" stainless flush mount allen head bolt is perfect! My closest Fastenal Google's to a mobile home park; not good. I wonder if I can hope to find this at my local hardware store?

BonS, My local hardware store had the flathead bolt I required and in metric too. Fastenal is expensive. Not too mention I like to shop the local guy to keep him here and the floor help are knowledgeable. Google gates idler pulley as it should bring up the Honda article that talks about all the options to make this change. |

|

|

|

|

Logged

Logged

|

|

|

|

|

bikerboy1951

|

|

« Reply #28 on: May 18, 2015, 01:42:01 PM » |

|

I have read the different methods of using the Gates pulleys, but am confused, In the preferred method it states to use a 3/8" hex bolt but further down it says to use a spacer on the head of the carriage bolt. So which bolt are they actually using. Is the enough space behind the pulley mounting plate to use a hex bolt without interference with the front of the engine. It also mentions doing some grinding, but what is being ground.

Of course, any and all help is always greatly appreciated.

Thanks.

Brad

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Big Tom 10628

|

|

« Reply #29 on: May 18, 2015, 04:30:52 PM » |

|

I have read the different methods of using the Gates pulleys, but am confused, In the preferred method it states to use a 3/8" hex bolt but further down it says to use a spacer on the head of the carriage bolt. So which bolt are they actually using. Is the enough space behind the pulley mounting plate to use a hex bolt without interference with the front of the engine. It also mentions doing some grinding, but what is being ground.

Of course, any and all help is always greatly appreciated.

Thanks.

Brad

I just did this Mod. The spacer referred to is required if the bolt that you use has a shoulder that would prevent the pulley from contacting the mounting bracket. Likewise the grinding refers to removing the shoulder so that a spacer is not needed. At least that's how I read it. I just used a bolt that did not have a shoulder. |

|

|

|

|

Logged

Logged

|

1999 Valkyrie Interstate

2006 Gold Wing

|

|

|

|

DK

|

|

« Reply #30 on: May 19, 2015, 09:29:04 AM » |

|

|

|

|

|

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|

Bambam650

|

|

« Reply #31 on: May 19, 2015, 10:02:44 AM » |

|

I like Method 1 using the T42015 bearing. The SS hardware can be purchased loose from the parts bins at Home Depot. Not sure why anyone would want to use any of the other methods.

|

|

|

|

|

Logged

Logged

|

1997 Standard (Black) original owner, bought new in August 1996

|

|

|

Skinhead

Member

Posts: 8732

J. A. B. O. A.

Troy, MI

|

|

« Reply #32 on: October 25, 2015, 02:18:59 PM » |

|

T42016 is available at Rock Auto Parts $16.32 ea + shipping. Just ordered 2.

|

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|