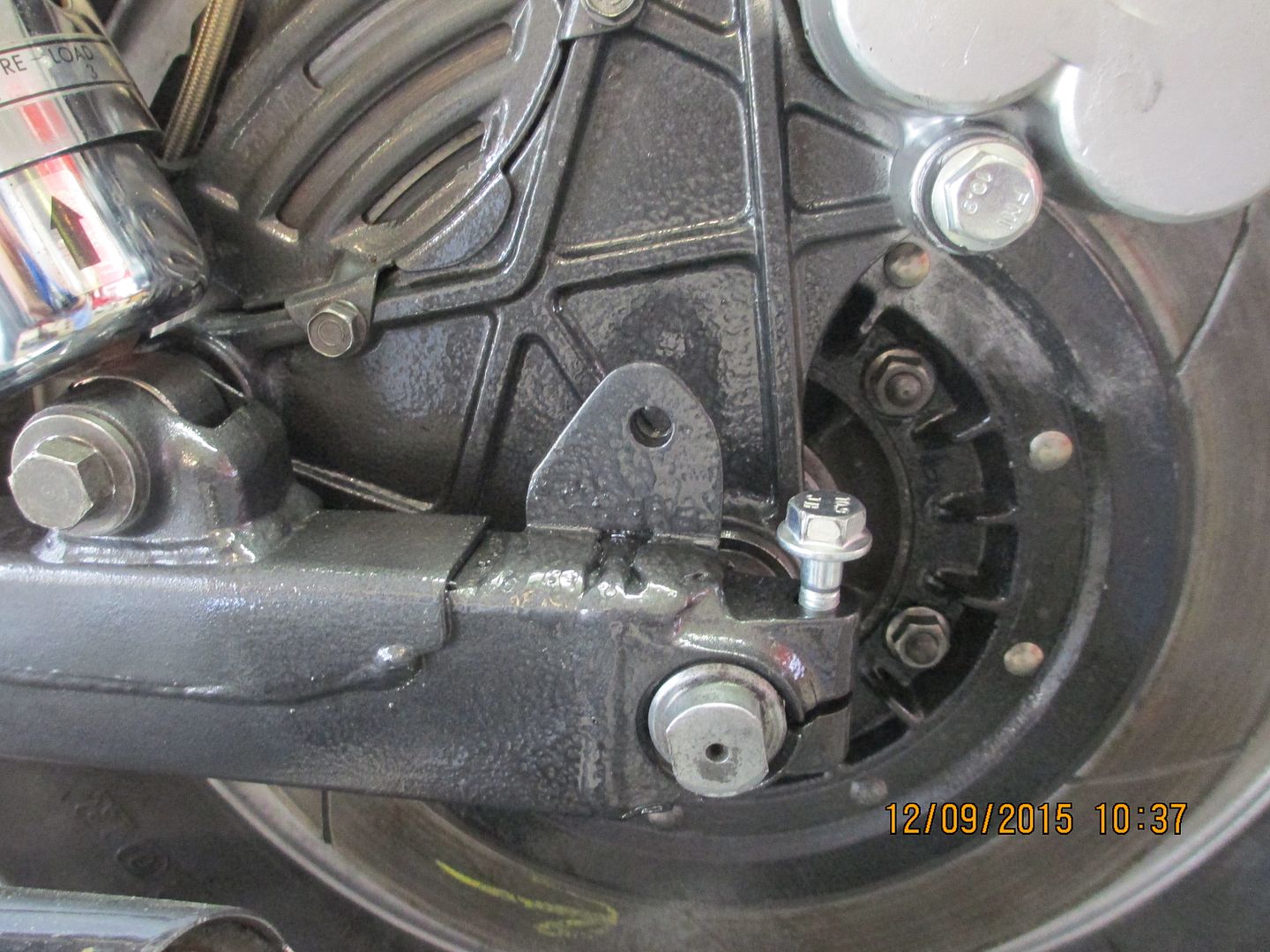

The first picture is how I mounted a bobber fender on my GL1200 project bike. I drilled through the swingarm, cut a piece of rubber for shock absorption and bolted it down as you see here. I cut a piece out of the end of each side of the fender and simply bent it back 90 deg. as shown.

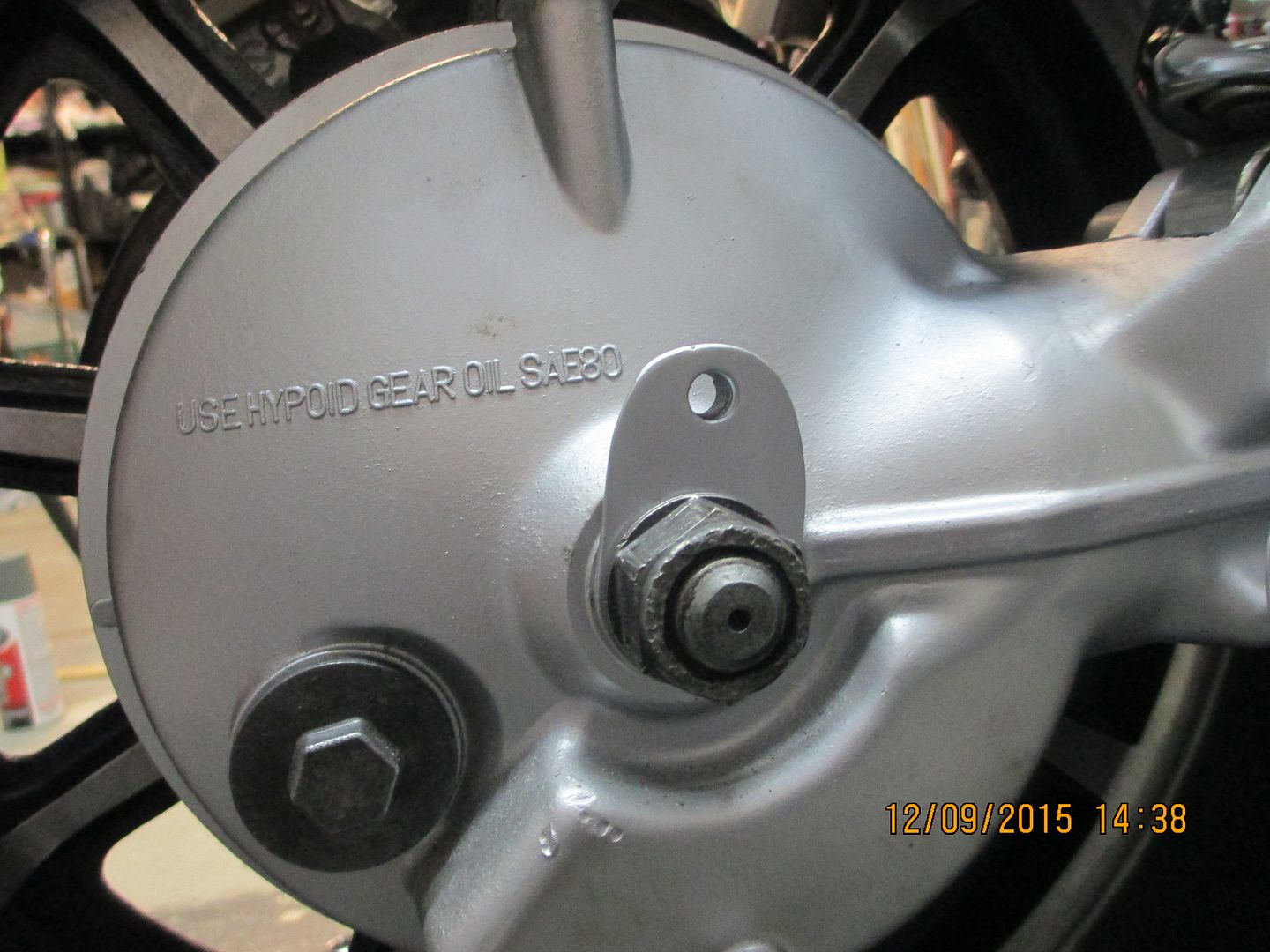

I shaped a piece as you see here, welded a nut on the back for the brace, then welded it all in place. Ground it down a bit so it didn't look quite so amateur then painted it. You can see by the fresh paint how much I cleaned off before welding. That let me attach the ground close to the weld spot to prevent spikes passing through the systems wiring harness. The axle for the 1200 goes in from the opposite direction as the Valkyrie.

For the brace on the other side, I merely cut a piece large enough to go over the axle after cutting a hole in it. I also welded a nut on the backside of this piece.

This is how the brace worked out for me, I've since reshaped the piece riveted to the fender so it matches the width of the brace. Also had to put a 45 deg. fitting in so the brake line would run behind the brace.

It appears on your picture you won't be able to go straight up from the swingarm on the left side. By cutting a piece such as I have under the axle nut, then run it up at a slight rearward angle, you should be able to bypass the brake line and caliper. Then attach the right side in a similar manner as I did with a piece welded to the s/a. My braces are SS so I'll not be painting them, just a good sanding and polishing and be done with it. Hope this at least gives you some ideas. My only problem now is I'll have to cut the frame off at the very back end because the fender hits it. Only about 2" on each side, looks you wouldn't have to on the Valk, the frame doesn't go back that far. I plan to cut each side off at a sharp angle so I can weld a nut on the inside after drilling a hole to run a bolt through. That way I can mount turn signals in there and run the wires inside the frame. Once done I can cover the ends of the frame tubing, maybe by shaping some thick rubber and gluing in place.