|

pago cruiser

|

|

« on: May 31, 2017, 06:21:33 AM » |

|

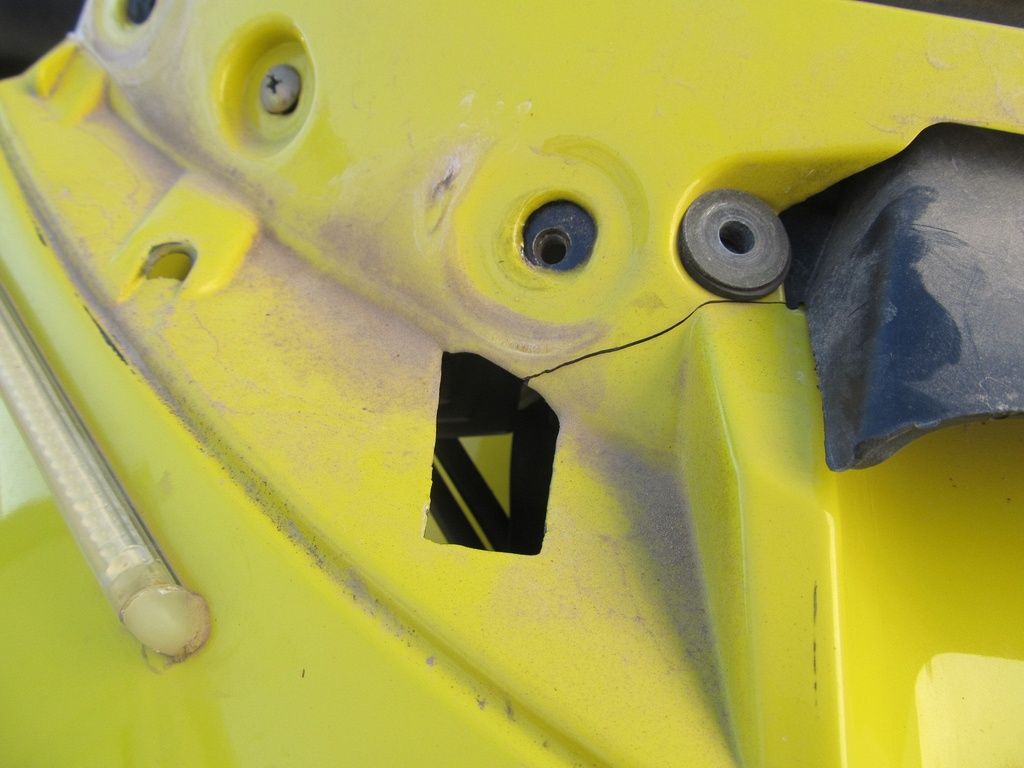

Have not been on the site in awhile - life and work... sigh. Still enjoying the solo and the hack Valks though  However... took apart the hack forks this weekend prepping to install the WASP leading link forks. We have maybe 5,000 miles on this since I built and painted. Note that the fairing was in as-new condition when installed.   Have had no impacts or accidents on the bike. This is vibration/mounting stress only. I think the cause is our driveway. 3 miles of dirt washboard, which generally is best handled by speed. The choice to traverse is either really slow (like walking speed) and loose your fillings, or about 40-45, slightly faster than the forks are capable of responding, which generally smooths things out. The question now is how to repair? Since this is all under the windscreen mount shield, I'm thinking to sand down the paint, rough up the abs, and use epoxy and fiberglass matt, front and back. Doing a google, others have simply used abs glue with a patch to bridge the crack. As can be seen by the pics, it would be hard to bridge these cracks with solid pieces of abs due to the (3) mounting holes directly adjacent. Comments welcome. |

|

|

|

|

Logged

Logged

|

Just because you are not paranoid doesn't mean they're not out to get you

|

|

|

dalai-lama

Member

Posts: 402

Wish I was out riding...

Watertown CT

|

|

« Reply #1 on: May 31, 2017, 06:52:48 AM » |

|

Get a piece of black ABS pipe from Home Depot and a can of MEK. Cut/grind down some of the pipe into small pieces. Put in a jar with the MEK covering it and let it set. This will produce an ABS slurry the consistency of peanut butter. Fill the cracked area with this and add some more for support. This will bind to the existing ABS like nothing else and basically become one piece again.

Then sand and paint. I have fixed quite a few things using just this technique. A crack in a saddle bag, the bolt loop in the center cover, a piece of the I/S pod, etc.

|

|

|

|

|

Logged

Logged

|

the dalai

|

|

|

pocket aces

Member

Posts: 630

2001 Standard / Well not so Standard anymore.

Tampa, Fl

|

|

« Reply #2 on: May 31, 2017, 07:17:06 AM » |

|

Get a piece of black ABS pipe from Home Depot and a can of MEK. Cut/grind down some of the pipe into small pieces. Put in a jar with the MEK covering it and let it set. This will produce an ABS slurry the consistency of peanut butter. Fill the cracked area with this and add some more for support. This will bind to the existing ABS like nothing else and basically become one piece again.

Then sand and paint. I have fixed quite a few things using just this technique. A crack in a saddle bag, the bolt loop in the center cover, a piece of the I/S pod, etc.

Great idea! I need to remember that. Does it have to be black ABS pipe? |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bagger John - #3785

|

|

« Reply #3 on: May 31, 2017, 07:38:10 AM » |

|

Get a piece of black ABS pipe from Home Depot and a can of MEK. Cut/grind down some of the pipe into small pieces. Put in a jar with the MEK covering it and let it set. This will produce an ABS slurry the consistency of peanut butter. Fill the cracked area with this and add some more for support. This will bind to the existing ABS like nothing else and basically become one piece again.

Then sand and paint. I have fixed quite a few things using just this technique. A crack in a saddle bag, the bolt loop in the center cover, a piece of the I/S pod, etc.

Great idea! I need to remember that. Does it have to be black ABS pipe? No, but it has to be ABS. Another alternative: Buy a hot-air plastic welder and use it along with ABS filler rod. I've successfully employed both methods to fix bike bodywork. |

|

|

|

|

Logged

Logged

|

|

|

|

|

old2soon

|

|

« Reply #4 on: May 31, 2017, 08:01:36 AM » |

|

Not much room inside for patches and the top-well that needs to remain close to what it is for reinstall. I was able to use a flat A B S plastic sheet and black A B S hardening glue to repair my saddle bags from the inside and fill the exposed cracks with the black A B S hardening glue as filler. The M E K and black A B S pipe pieces to create a slurry sounds like one of those-Why In the heck didn't I Think of that!  IF you can get smaller pieces inside to cover the crack and reinforce the area Maybe a sacrificial A B S faring piece or a sacrificial A B S saddle bag piece? The sheet of flat A B S I got from Amazon was 1/8" thick. The MOST difficult part of repairing my bags was waiting the 24 hrs for the glue to set up PROPERLY. DO NOT rush it. I waited the 24 hrs because I was holding the cracks closed with wood working clamps and there was some tension trying to force the crack back open. 24 hrs allowed the glue to dry And cure. As you only want-not really-to do the repair ONCE don't rush it. RIDE SAFE. |

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

Steel cowboy

Member

Posts: 1291

Moving ahead so life won’t pass me by.

Spring Hill, Fl.

|

|

« Reply #5 on: May 31, 2017, 08:39:42 AM » |

|

I would add some fiber glass chop strand to the repair. I have made repairs on my R/C aircraft cowlings adding this "slurry and glass" combo with no repeat repairs in the same locations.

|

|

|

|

|

Logged

Logged

|

2001 black interstate

2003 Jupiter Orange wing

|

|

|

|

pago cruiser

|

|

« Reply #6 on: May 31, 2017, 09:32:30 PM » |

|

Thanks all.

Think I'll try the MEK/abs route; certainly sounds like it would work. One question; I have done epoxy/fiberglass with mixed results in the past; the glass held up, but the epoxy came loose from the abs. As the MEK is basically making new material, would it be possible to add a layer of fiberglass? I'm not sure how the MEK would react with it; it the fiberglass did not absorb the MEK, it would probably be useless.

|

|

|

|

|

Logged

Logged

|

Just because you are not paranoid doesn't mean they're not out to get you

|

|

|

|

Bagger John - #3785

|

|

« Reply #7 on: June 01, 2017, 05:14:38 AM » |

|

MEK is a solvent. It's not making the new material; the ABS which you dissolve in it will.

And...you cannot bond fiberglass straight to ABS without using some kind of intermediary. This is why the poster above mentioned adding shredded-up matting to your slurry.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

old2soon

|

|

« Reply #8 on: June 01, 2017, 08:01:04 AM » |

|

The WHY of me suggesting the THIN pieces of A B S over the cracks.  RIDE SAFE. |

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

|

pago cruiser

|

|

« Reply #9 on: June 01, 2017, 09:49:50 PM » |

|

Thanks again guys.

Yes, I got the MEK dissolving the abs pieces for "new material".

What I was questioning is if fiberglass matt would be of benefit.

Fiberglass matt actually absorbs epoxy, which when hardens makes the fiberglass/epoxy much stronger than the epoxy itself.

If the fiberglass does not absorb the MEK, I'm thinking it would probably be useless.

|

|

|

|

|

Logged

Logged

|

Just because you are not paranoid doesn't mean they're not out to get you

|

|

|

|

Bagger John - #3785

|

|

« Reply #10 on: June 02, 2017, 06:37:46 AM » |

|

If the fiberglass does not absorb the MEK, I'm thinking it would probably be useless.

It'll add a little structural rigidity by virtue of being enmeshed in the ABS and increase its shear strength somewhat. Not by a huge factor, mind you, but possibly enough to prevent recurrence of the cracking. I'd also look into ways to mechanically isolate that area of the fairing from the mount, so it's not rigidly connected and subject to stress transmission. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Jess from VA

|

|

« Reply #11 on: June 02, 2017, 06:52:32 AM » |

|

I fiberglassed (mat and resin) a set of ABS HOG lowers years ago (long cracks). It was strong and held very well for several years (say 5), but it finally did start letting go (separating, slowly, not all at once). I thought to add more resin and glue them down again, but I had stopped running them as they were too hot in summer, and a PITA to take on and off, and just left them off.  I did not know that fiberglass and ABS were supposed to be incompatible at the time, but believe my problem was mostly because of failing to really rough up the surfaces before application. Other than a good cleaning, I just laid mine in on smooth ABS. But I used a lot of glass and resin (on the inside of these, vertically at the inside big bends). |

|

|

|

« Last Edit: June 02, 2017, 06:58:51 AM by Jess from VA »

|

Logged

Logged

|

|

|

|

|

Bagger John - #3785

|

|

« Reply #12 on: June 02, 2017, 07:50:14 AM » |

|

ABS - for that matter, any petroleum-based plastic - is difficult to bond to with regular ol' epoxy because of its oily composition. May not seem "slippery" to humans but to glues it's a different proposition. Roughing up the surfaces gives a little more 'tooth' (area) for the epoxy to bond to but in the end it's the chemicals which get ya.

There are adhesives which are specifically designed to join dissimilar materials without solvent action. My former employer used them in their products. Would need to check with the polymer engineering gang to see what they recommend for an ABS to fiberglass joint.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

pago cruiser

|

|

« Reply #13 on: May 27, 2018, 07:39:22 PM » |

|

Time to resurrect my old thread...  Was having some odd noises from my IS Fairing on my ADV driveway... finally got it apart today: Dangit.    While the earlier "grind up abs material into dust and mix with MEK and apply to the cleaned area" worked relatively well ( I think - guess I need to check the fairing on that bike soon - but it has not been making strange noises) it does take a bit of time to grind up the abs, mix, and then wait the 12 hours for it to fully harden. Anybody ever tried the Harbor Freight welder routine? Had another project where a friend used some ABS welding to great success, but his equipment was way different.  Reviews on the HF site are...mixed.  What I was thinking was to clean off the paint, open the cracks a bit, weld the cracks on both sides, and then span the "top" half of the rectangular opening (that is used for a recess for the mating trim piece) with some slightly bent ABS flat stock. I could span and weld an ABS piece in from above the black line I marked. The mating trim alignment piece does not go past that line. TIA. |

|

|

|

|

Logged

Logged

|

Just because you are not paranoid doesn't mean they're not out to get you

|

|

|

|

da prez

|

|

« Reply #14 on: May 28, 2018, 06:23:09 AM » |

|

I have just started experimenting with a soldering iron with a flat blade. A wood burner (if still around) should work. clean and rough up the surfaces. I get the pieces together and run the hot blade in the crack. Then do the solvent weld. The mek method in going to be used on the next bike I bought. Over fill the patch on the inside. After cured , grind to shape. I use abs black plastic glue like bondo for a finish. On the outside , if no holes , use the abs to build up the surface and sand smooth when cured. Prime and paint.

da prez

|

|

|

|

« Last Edit: May 29, 2018, 07:25:51 PM by da prez »

|

Logged

Logged

|

|

|

|

|

¿spoom

|

|

« Reply #15 on: May 29, 2018, 12:01:50 PM » |

|

FWIW in a fiberglass procedure, the polyester resin is catalyzed with a peroxide MEK-P not unlike with Bondo. Bondo is a Polyester product, also. The fiberglass is actually very thin strands of actual glass, which makes it inert. Cured resin alone would be very brittle, and break like well, peanut brittle. The same applies with Bondo, which is why anything thicker than around ¼" needs reinforcing material (glass) like in the "tiger hair" variety Bondo. By encapsulating the flexible fiberglass strands in the more rigid Polyester media, they have a combined flexible strength but they DON'T actually combine their makeup any more than nails do when driven into wood. Fiberglass cloth stays in mat form because of a binder that's sprayed on it to hold it together, and this binder is dissolved by the resin when you wet down the mat/cloth/roving. This may make it look like the mat is dissolving but it isn't. Without the binder to temporarily hold glass mat together, it'd be like trying to build something with a wet drain's hair clog. Unless polyester will stick to ABS, it won't really work with ABS except as a surface bond, so yeah, you'd REALLY need to rough the surface with maybe 80 grit (or even more coarse) dry paper so there'd be a chance of the resin hanging on to it like a bunch of teeny Velcro hooks. To reinforce with strands of glass, I'd use a length of chopper gun strand. It'd just glass strand with no binders which looks just like the cheap white poly twine used at lumber yards, except it's actually glass. Cut it into maybe ½" lengths and it'll be easily separated into individual hairs to mix into the ABS slurry. I'd go sparingly and try it on scraps of ABS to see how much/little to mix in, and how strong it is afterwards.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Paladin528

|

|

« Reply #16 on: May 30, 2018, 10:08:00 AM » |

|

One thing I have tried with some success is to use ABS glue to chemically bond the broken pieces togerther. Then follow up with some form of re-enforcement. I use an ABS product that comes with a mesh screen to re-enforce the area.

Be very careful using ABS glue as it will melt any ABS it touches.

I have also used acetone to melt ABS pellets into a slurry. when used for a repair it will chemically bond with the ABS being repaired and after a LONG curing process will have similar strength to the original material but will require sanding and painting when complete.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

john_berry

|

|

« Reply #17 on: May 30, 2018, 12:57:06 PM » |

|

I would use SEM Quickset 50. It's a two part structural adhesive that works perfectly in a situation like this. You can find it on ebay. It dries to the touch in about 3 minutes and dries completely in about an hour. You can use it to bond what ever reinforcement you desire over the cracks. The only drawback is you'll need to find an applicator to dispense it.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

pago cruiser

|

|

« Reply #18 on: May 30, 2018, 09:13:44 PM » |

|

Thanks all, While I was going to buy the welder, this stuff all has a learning curve; and right now I am just out of time. Took it to my painter, and he: 1. Patched half the opening with an abs filler piece using a soldering iron type of welder. 2. Applied a light SMS adhesive to the joints - it was called "Door Skin and SMC Adhesive"; he was not aware of the Quickset 50 - but once he finds something that works he just rolls with it - makes sense I guess. 3. He then cut some plastic mesh that has proven to work good with the SMS stuff, and applied it to a larger area - covering the patched piece as well. 4. Then more SMS adhesive over the mesh, working it into the mesh with his fingers. 5. We decided to patch half the "hole" just below the windshield mounts - there is no reason for these to be so big, and the opening ends up being the weak point/highest stress point in the system. Hence where all cracks start. Looks like it ought to work: Left outside:  Left inside:  Right outside:  Right inside:  Now what I really wish for is that the guy grading our communal 3 long mole driveway would do it a little more often... this road is hell on vehicles  But I guess it also keeps the place isoplated, which is good...  |

|

|

|

|

Logged

Logged

|

Just because you are not paranoid doesn't mean they're not out to get you

|

|

|

|

Paladin528

|

|

« Reply #19 on: May 31, 2018, 04:18:53 AM » |

|

This looks exactly like what the Body shop did for me. They use this on plastic bumpers and such. works awesome.

|

|

|

|

|

Logged

Logged

|

|

|

|

|