John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« on: December 10, 2015, 05:22:40 PM » |

|

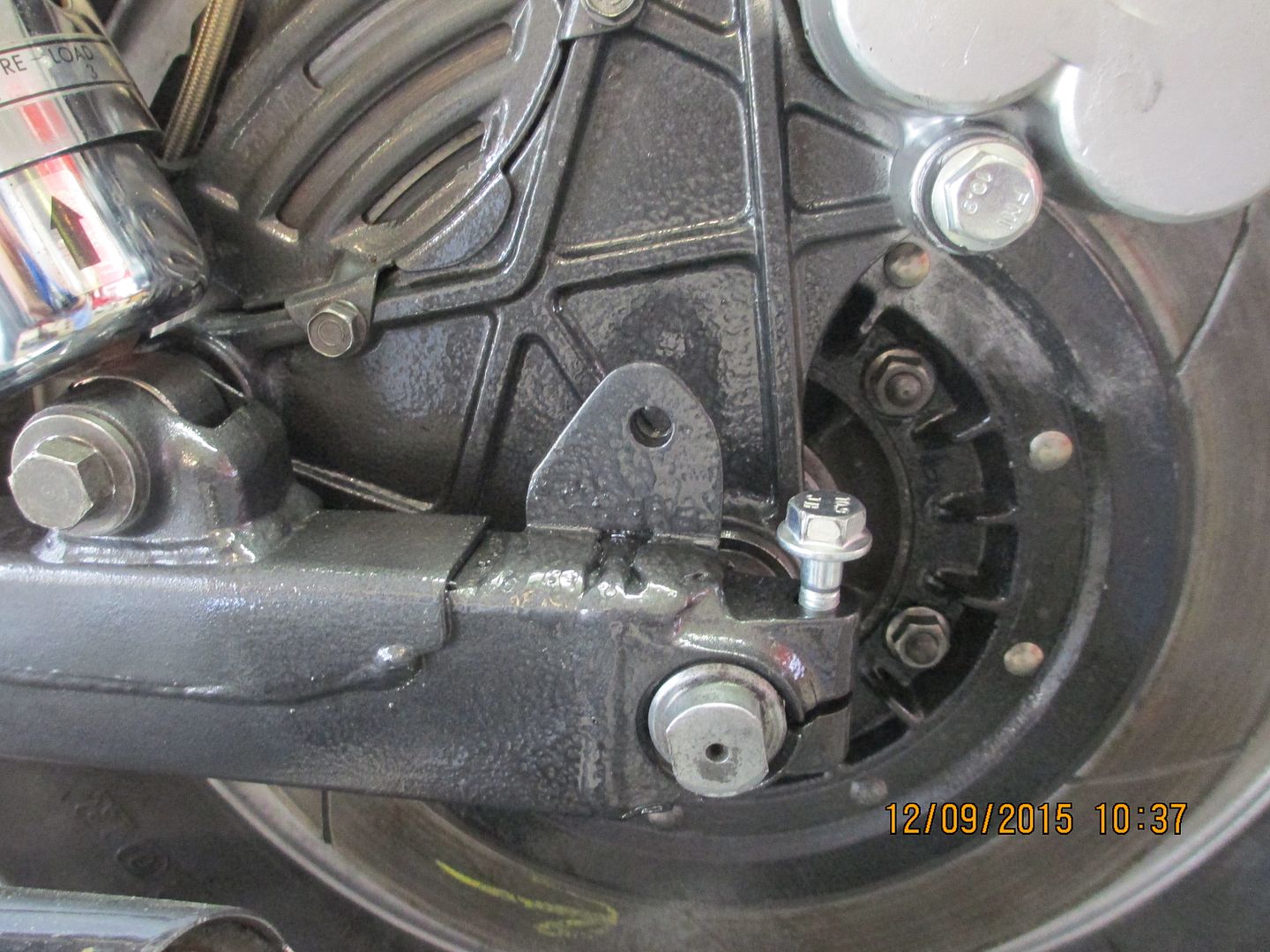

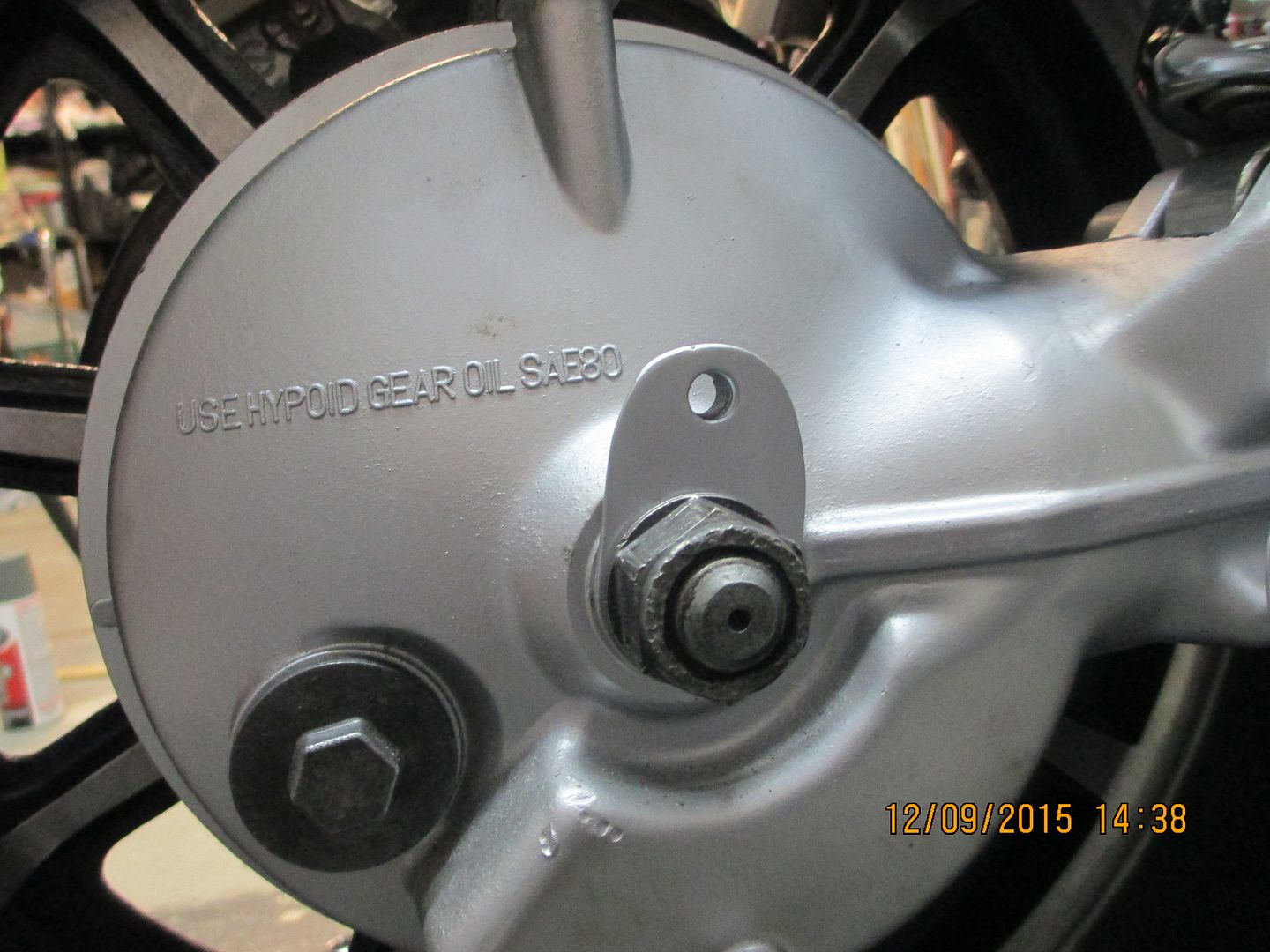

Does anyone know if the 304 or 316L type SS flat bar can be polished? I'm looking at a piece of 1/8" x 3/4" x 72" of 304, but I want to be able to sand it down and polish it so need to know if it's possible with that grade or whatever the numbers mean. I'm using it to make braces for each side of the rear fender I'm mounting on my 1200 project. I've welded a mount to the swingarm on the left side and fabbed a mount to go on the axle on the right side under the axle nut. Next step is to fab up some braces to go from the mounts up to the fender. I'm mounting the fender to move with the s/a instead of mounting it solid. The frame and s/a are painted a hammered black, so used the same stuff on the left bracket after I welded it to the left side. I also welded a nut on the back of each bracket so fumble fingers like myself wouldn't have a hard time bolting a brace on. The fender will be black and silver to match the tank off a '99 Valk, and the OEM silver front fender. Just thought the addition of a polished SS bracket on each side would look kinda nice. Left side bracket for fender brace.  Right side.  I stuck the ruler up there to give an idea of what I'm wanting to do.  Front fender mount. Doing this due to a large gap between the tire and fender if I mount it solid to the frame. This way I can have the fender ride just a half inch or so above the tire and have it move with it.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

NEHI

|

|

« Reply #1 on: December 10, 2015, 05:43:52 PM » |

|

304 is your best SS for polishing. Most SS mirrors are 304.

|

|

|

|

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #2 on: December 10, 2015, 05:51:22 PM » |

|

Thanks, that's what I needed to know.  |

|

|

|

|

Logged

Logged

|

|

|

|

RDKLL

Member

Posts: 1222

VRCC #1231 VRCCDS #271

Mesa, AZ

|

|

« Reply #3 on: December 10, 2015, 06:01:06 PM » |

|

I am going to eventually doing something like that too on my Valk bobber....found out fenders are not required in AZ...but will still want to do something eventually...probably more towards a half diameter, just to keep the water off  |

|

|

|

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #4 on: December 10, 2015, 06:55:01 PM » |

|

If you get your tires a little wet then run through some dirt or fine, loose gravel, you'll be thankful for a rear fender. Your back will feel like Dick Chaney took a pot shot at you.  On the fender I'm working with, I want to cut 6" off the back end and bring it to more of a point. I just need to get it mounted solid first so I can experiment with a grease pencil and some tape to outline different shapes for the back edge. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Karen

|

|

« Reply #5 on: December 10, 2015, 07:01:31 PM » |

|

Nice work, John!

|

|

|

|

|

Logged

Logged

|

|

|

|

RDKLL

Member

Posts: 1222

VRCC #1231 VRCCDS #271

Mesa, AZ

|

|

« Reply #6 on: December 10, 2015, 07:04:46 PM » |

|

I am considering a 215/50 or /55 car tire and then a close hugging fender....

|

|

|

|

|

Logged

Logged

|

|

|

|

|

dreamaker

|

|

« Reply #7 on: December 10, 2015, 07:05:10 PM » |

|

I don't know if you do know, but when you drill or saw stainless you have the run it at a slower speed with some pressure, then regular steel. If not, then you will wipe out the bit or blade. Also, kind of rule of thumb, if a magnet don't stick to the stainless, usually good for polishing, the "L" stands for low carbon, the stainless they use in kitchen I believe is 700 series and is magnetic, it grains nice. 304, 306, 316, can look like chrome. Also harbor freight has polish for stainless, I think it is the white stuff.

|

|

|

|

« Last Edit: December 10, 2015, 07:12:12 PM by dreamaker »

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #8 on: December 11, 2015, 07:49:54 AM » |

|

I don't know if you do know, but when you drill or saw stainless you have the run it at a slower speed with some pressure, then regular steel. If not, then you will wipe out the bit or blade. Also, kind of rule of thumb, if a magnet don't stick to the stainless, usually good for polishing, the "L" stands for low carbon, the stainless they use in kitchen I believe is 700 series and is magnetic, it grains nice. 304, 306, 316, can look like chrome. Also harbor freight has polish for stainless, I think it is the white stuff.

Yes, I found that out the hard way years ago, thanks for the reminder. Had one highly irritated father until I replaced some bits and blades.  I've used the various polishing stuff on SS, if it's rough I usually will start out with some fine sandpaper then move to wet sand with 1000 or 1500. Finish off with the buffing wheel. It does come out looking like chrome. I plan to leave the braces unfinished until I have everything cut, bent, shaped, & drilled....ready to put in place. Then I'll polish. |

|

|

|

|

Logged

Logged

|

|

|

|

|

da prez

|

|

« Reply #9 on: December 11, 2015, 08:26:11 AM » |

|

Magnetic stainless is also known as chrome metal. It can be worked just about the same but should be a lot cheaper.

da prez

|

|

|

|

|

Logged

Logged

|

|

|

|

|

dreamaker

|

|

« Reply #10 on: December 11, 2015, 10:49:30 AM » |

|

I don't know if you do know, but when you drill or saw stainless you have the run it at a slower speed with some pressure, then regular steel. If not, then you will wipe out the bit or blade. Also, kind of rule of thumb, if a magnet don't stick to the stainless, usually good for polishing, the "L" stands for low carbon, the stainless they use in kitchen I believe is 700 series and is magnetic, it grains nice. 304, 306, 316, can look like chrome. Also harbor freight has polish for stainless, I think it is the white stuff.

Yes, I found that out the hard way years ago, thanks for the reminder. Had one highly irritated father until I replaced some bits and blades.  I've used the various polishing stuff on SS, if it's rough I usually will start out with some fine sandpaper then move to wet sand with 1000 or 1500. Finish off with the buffing wheel. It does come out looking like chrome. I plan to leave the braces unfinished until I have everything cut, bent, shaped, & drilled....ready to put in place. Then I'll polish. Back in my Fab. days I worked allot with stainless steel, drill, cut, weld and so on. This is very important, if you polish your own stainless. Any buffing or sanding wheels or anything you have used on steel, never use it on stainless or any non rusting metals. If you have doubt about the buffing pads, don't use them. The reason is if there is the slightest or micro particles in the buffing or polishing material of iron, your stainless, brass, copper or aluminum, it may rust on you, because it can get impregnated into what you are polishing. So when in doubt, don't use it! HF has what you need. Just FYI! |

|

|

|

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #11 on: December 11, 2015, 10:55:12 AM » |

|

Dreamaker, never thought of that but makes sense. I'll pick up a different wheel and keep it with my SS stuff. I found a 6' piece of 304, it's 1/8" x 3/4", less than $30 with free shipping. Figure a couple 3/16" rivets should be plenty strong enough to hold the fender on the top of the brace.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

dreamaker

|

|

« Reply #12 on: December 13, 2015, 07:19:09 AM » |

|

Let me pass on one more little thing. It is Aluminum vs. Bare Steel, they don't like each other. Often we make parts out of aluminum, its cheap, easy to work with, probably the most attractive thing, it buffs up like chrome. When you attach aluminum to bare steel, as in bolts brackets, or just contact, the aluminum will corrode into a white like powder. And from my experiences I have seen bolt to appear to like weld themselves to the aluminum.(boat outdrives for example) So I guess the simple answer and solution is don't let bare steel come in contact with aluminum. Aluminum is compatible with nickel, such as chrome, stainless various nonferrous metals,and so on. If for some reason you need to attach aluminum to steel, you need a barrier, like a form of a gasket. A gasket can be considered as a coating like paint, plating, or some type of material, but if the barrier degrades, it will corrode. I have even noticed an aluminum part that was polished, the polish itself on the aluminum part became a barrier for a period of time. So if you use bolts, use chrome or some form of plated or coated, stainless, nonferrous metals, should be the ticket. If you noticed on your bile the bolts appear to have a coating or plating on them, sort of remind me of military hardware bolts. Myself every time I go to the marine supply store, I pickup a couple of stainless bolts and replace the ones on my bike with stainless and they buff up real nice. Just something I learned and wanted to pass it on, so one day you don't have to use a breaker bar to remove a bolt on your bike. THINK SUMMER!!!!

|

|

|

|

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #13 on: December 13, 2015, 09:12:09 AM » |

|

Dreamaker, I know all too well of what you're talking about....past experience was a good teacher. As for the fender, it's rolled steel, to be held in place with SS braces and SS rivets. The brackets the braces will be bolted to are also steel and will be with SS bolts. Yesterday I cranked up my compressor and with the die grinder and cutting wheel, I removed 6" from the back end of the fender. I like the looks much better.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

dreamaker

|

|

« Reply #14 on: December 13, 2015, 09:33:07 AM » |

|

I figured you being a creative person you are, you probably already knew, but just in case, and to share with others wouldn't hurt!

|

|

|

|

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15325

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #15 on: December 13, 2015, 09:46:46 AM » |

|

I figured you being a creative person you are, you probably already knew, but just in case, and to share with others wouldn't hurt!

Agreed.  |

|

|

|

|

Logged

Logged

|

|

|

|

RDKLL

Member

Posts: 1222

VRCC #1231 VRCCDS #271

Mesa, AZ

|

|

« Reply #16 on: December 13, 2015, 11:05:31 AM » |

|

Looks good John, I am going to be going in very similar direction except the the swing arm side mounts will be a little forward so that both sides will be mounted to the swing arm and not the final drive. I will be going to a car tire eventually, probably a 215 and then a hugger fender. Since it does not rain in AZ too much, been lucky and in 3 weeks not got caught by the reain once

|

|

|

|

|

Logged

Logged

|

|

|

|

|