|

RonW

|

|

« on: August 04, 2020, 04:05:24 PM » |

|

Complete duck head systems are sold for $500 after shipping costs. The duck head itself is available on ebay for $20. As soon as the parts arrive, the plan is to fabricate a duck head mount/demount tire changer. It's used on top of the Harbor Freight base. If you have previous experience with this, please clue me in.    To dismount a tire, pry the bead over the duck bill and rotate the duck head. There's a notch for your tire iron. The rotation is always counter-clockwise for dismounting or mounting such that the duck's head is the trailing edge. It works like this and this and this.   To mount a tire, position the bead under the duck head and use a clamp, etc. It works like this and this.  |

|

|

|

« Last Edit: August 05, 2020, 08:19:50 AM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #1 on: August 05, 2020, 09:03:15 AM » |

|

I haven't. But it sure looks interesting. Looking forward to the review.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

wingrider02

|

|

« Reply #2 on: August 08, 2020, 06:54:46 AM » |

|

It will be interesting to hear how it works for you....might be just what is needed!

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #3 on: August 09, 2020, 04:17:21 AM » |

|

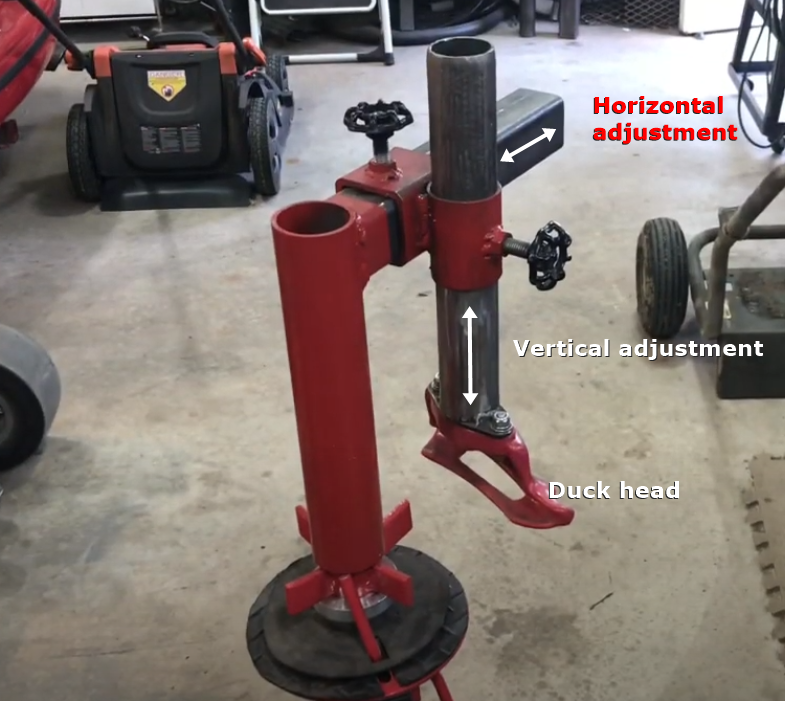

I just report, wingrider and Meathead. You decide. I'm retiring this year and I don't want to wrestle with tires nomore. Until I came across the duck head thingie on ebay, I wasn't aware that duck heads have been used on professional tire changers for a while. The main difference with the diy versions, is that professional tire changers hold the duck head stationary and rotate the wheel, while diy versions hold the wheel stationary and the operator rotates the duck head to mount or demount the tire, like here. Most diyers include a vertical adjustment and a horizontal adjustment to align the duck head to the rim. The horizontal adjustment is to match the radius of the wheel.    The simplest design (and my beta) is bolting a heavy duty bar to the duck head which is then used like the No-mar bar or the Harbor Freight bar. However, it doesn't have vertical and horizontal adjusters, but it seems to work, here.  Most diy versions have a vertical offset to clear the brake rotor etc.  The way the duck head is designed, it has a 2¾-inch vertical offset which might provide sufficient clearance for the beta design above, here.   Btw, most of the diy versions seen on YouTube aren't designed for motorbike wheels as the center post won't fit in axle hole.  |

|

|

|

« Last Edit: September 06, 2020, 07:05:33 PM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #4 on: August 10, 2020, 04:58:04 PM » |

|

I'm going to order one and try it on a simple bar. Thanks for the post.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #5 on: August 10, 2020, 09:27:38 PM » |

|

You might review the video below, here, which I advanced however you might find it beneficial to review the video from the start.  Notes: for my beta design, I prefer a flat surface (rectangle) which is more ideal to bolt on a flat plate. A heavy gauge lever then is welded to the flat plate, so on.  The stainless steel version is designed to a attach a vertical pipe. It has rim protectors.  This version is recessed to seat a metal plate designed to hold a vertical post.  ..... or like this.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #6 on: August 11, 2020, 08:53:44 AM » |

|

Thanks, I already have the red one coming from Amazon. If it doesn't work with the simple bar, I'll weld up the mount system you posted.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #7 on: August 11, 2020, 06:55:56 PM » |

|

Meathead, you'll probably start on your duck head before I do. I'm changing over my mig welder to flux core (FCAW) since the argon gas to run mig is too expensive. To do this I need to replace the drive wheel in the mig. The flux core drive wheel is on its way but it might take a month to get here. The local welding stores are out of the drive wheel I need and it'll take just as long for the local welding stores to restock. I'll be posting another post after this post which will be the final post on this thread just boiler plate notes on building the duck head of interest. Thusly, I'm officially handing off the topic of duck heads to you since you'll start on it before I do and you minus well start your on thread on the subject if you like ofcourse. |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #8 on: August 11, 2020, 07:05:12 PM » |

|

Meathead, you'll probably start on your duck head before I do. I'm changing over my mig welder to flux core (FCAW) since the argon gas to run mig is too expensive. To do this I need to replace the drive wheel in the mig. The flux core drive wheel is on its way but it might take a month to get here. The local welding stores are out of the drive wheel I need and it'll take just as long for the local welding stores to restock. I'll be posting another post after this post which will be the final post on this thread just boiler plate notes on building the duck head of interest. Thusly, I'm officially handing off the topic of duck heads to you since you'll start on it before I do and you minus well start your on thread on the subject if you like ofcourse. Well.....I've been known to procrastinate before  But, once I get it done, I'll post back here with some pics. I don't need tires yet, but I have an extra rear wheel that I'll likely use it on. |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #9 on: August 14, 2020, 11:15:27 AM » |

|

Welding a lever to a mounting plate is the easiest way to make the duck head tire changer .....  .....however, things can get sloppy rotating the lever around the center post (x). This might lead to an issue mounting the last 12-inches of a stiff Valk tire to the rim.   Might be better off drilling a hole in the lever so the center post can be used as an axle for the lever. This also keeps the duck head level rotating it around the rim. This requires a horizontal adjuster to match up the rim radius, like below and here.   Harbor Freight motorbike tire attachment.  The duck head has a curve molded into it. The lever should be welded square to the mounting plate to keep the curve in the duck head concentric to the wheel radius.  Or, you could slot one of the two holes in the mounting plate (arrow).  Random notes. In the rendition below, a round pipe is used for the vertical adjustment. Maybe the fabricator ran out of square tubing, however a round pipe allows the duck head to be adjusted concentric with the wheel radius.  At A, if the arc on the duck head extends from 2 o'clock to 4 o'clock centered on the lever, the same arc transposed on the offset vertical adjuster at B won't be concentric with the wheel radius at its offset position. The correct arc is instead from 2.5 to 4.5, so on. Is this level of precision even necessary? IDK.  Motorbike tire changers available in Europe. $280 plus shipping and vat.  |

|

|

|

« Last Edit: September 06, 2020, 10:49:03 AM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #10 on: August 14, 2020, 12:43:49 PM » |

|

RonW, first off, thanks for all the top notch pics, diagrams, explanations. You always provide good stuff.  After looking at some of the pics I have rethought my plan for a simple straight bar. I never take off my discs when changing tires. The straight bar looks to pose too much of a chance to damage them. I could just put a dogleg in it. But then I might as well complete the center pivot for it. |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #11 on: August 14, 2020, 02:36:33 PM » |

|

I might as well complete the center pivot for it.

Let us know how you do it when you get around to it. This is all she wrote for my thread on the topic. All my material hasn't arrived in the mail yet. Them ducks in a row. Meanwhile, thinkin ain't doing. |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #12 on: September 03, 2020, 12:47:47 PM » |

|

I might as well complete the center pivot for it.

Let us know how you do it when you get around to it. This is all she wrote for my thread on the topic. All my material hasn't arrived in the mail yet. Them ducks in a row. Meanwhile, thinkin ain't doing. I told you I would likely procrastinate.  I finally got around to doing something, and after checking measurements, it looked like simpler would be better. If it doesn’t work I will modify for a center pivot. For now it looks like I can just use my threaded rod as a leverage point.   |

|

|

|

« Last Edit: September 03, 2020, 01:34:39 PM by meathead »

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #13 on: September 04, 2020, 01:20:31 AM » |

|

Incredible idea using angle iron for the lever! Wouldn't have occurred to me even if I tripped over the same piece of angle iron. Anyways, I guess that answers the question if the duckhead's own vertical offset is high enough to keep the lever from banging into the rotor, etc.

..... If it doesn’t work I will modify for a center pivot.

If a pivot is necessary, a pivot is easily done by grinding off a section of the angle iron. If that weakens that section of the angle iron, simply reinforce the proximity with a flat plate etc. An advantage of a pivot is it keeps the duckhead/lever level during the rotation. Perhaps important getting the final section of the tire on the rim. Another option is to notch the edge of the angle iron to get a positive purchase on the pivot rod ..... again if that's even necessary, like this.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #14 on: September 04, 2020, 05:54:16 AM » |

|

Honestly, I can't take much (if any) credit for coming up with the angle iron idea. I had in my mind to use square tubing like in the examples. But when I went out to start on it, I didn't have any long enough. And I was too lazy and cheap to run to Home Depot for some. I looked at my pile of scrap metal and saw some old bed frame angle iron, and thought it might work. But, I couldn't figure out how to make it adjustable. After measuring, and setting the wheel in place, I think it will work. My plan is to slip a piece of pvc over the threaded rod for the leverage. I use that rod with a plate and nut for clamping the wheel down from moving. The issue of a center pivot becomes a problem with the angle iron, because of the difference in the front and rear wheel diameters. I will take some pics and maybe a short video when I use the tool. Thanks for originally posting up this idea.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #15 on: September 04, 2020, 03:11:30 PM » |

|

The cost of square tubing is astronomical and they're not readily available in thick wall. Absolutely, post a video and/or pics, moreso if the ducky actually works on a Valk's tire. So far it's only, it's only conjecture. As R-D would state, it's all conjecture. Thus, you must slay the conjecture. So, forth. A bonus with the ducky which is nylon is that rim protectors aren't necessary anymore, I think.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #16 on: September 04, 2020, 03:13:26 PM » |

|

So, I have a report on the duckhead. The short version is it worked well on the dismount. I didn’t do a mount yet. But I expect it to work well. For the extended version, here goes. I thought I’d start off with showing my red neck bead breaker.  I got started on the dismount.  But ran into a problem. As I was using the bar the wheel kept slipping, I tightened it up and tried again. Still slipped. Then I realized the duckhead was catching the corners of my plywood. It’s not been an issue when using tire irons. But they stuck out just enough to catch with the bar.  After sawing off the corners, all was well. It worked well. The duck head doesn’t fit good on the Valkyrie rims though. They are shallower than a car rim. But, I could get the dismount portion of the head to match up.  I believe for mounting I can get the other side to match up well also. You just can’t get the whole duck head to go in at once.  So in total, I believe it to be a success and well worth the time to do.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

The emperor has no clothes

|

|

« Reply #17 on: September 04, 2020, 03:20:15 PM » |

|

The cost of square tubing is astronomical and they're not readily available in thick wall. Absolutely, post a video and/or pics, moreso if the ducky actually works on a Valk's tire. So far it's only, it's only conjecture. As R-D would state, it's all conjecture. Thus, you must slay the conjecture. So, forth. A bonus with the ducky which is nylon is that rim protectors aren't necessary anymore, I think.

Yes, absolutely no rim protector is needed. Maybe when using a tire iron to get the second bead over the duck head would be a good idea. I didn’t as I wasn’t really going to be prying on it. Just lifting it over the end of the head. I’m thinking maybe of grinding the bottom lip of the duck head down, so that it fits more flush with the Valkyrie wheels. I’ll wait and see how a mount goes first. The dismount worked just fine though. |

|

|

|

« Last Edit: September 04, 2020, 03:22:44 PM by meathead »

|

Logged

Logged

|

|

|

|

|

|

|

RonW

|

|

« Reply #19 on: September 04, 2020, 07:08:49 PM » |

|

nada, this video instead. Read my next post.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

RonW

|

|

« Reply #20 on: September 04, 2020, 09:33:31 PM » |

|

The duck head doesn’t fit good on the Valkyrie rims though. They are shallower than a car rim. But, I could get the dismount portion of the head to match up.

I was expecting better of the ducky, but what do I know. From your pic, the issue is the lip (A) which goes under the rim is too long preventing the ducky from flushing up with the circumference of the wheel.  And you can't grind down the lip (A) because in the same motion you'd grind off the reinforcement strip (B), next two pics. I dunno if the ducky would be sturdy enough altered that way and you can't put back the pieces you ground off.   The black version of the ducky (arrow) doesn't have the same issue.  ..... it's simpler L-shape profile (A) doesn't have the problematic lip that goes under the rim (B). [edit] The lip (B) if the proper size and shape is a plus.  ..... but it does have a recess for a metal plate. Even a piece of plywood would fill the void though.  Another disadvantage of the black duck head is the vertical offset isn't as high as the red ducky (arrow). Spacers would gain you more vertical offset up to a point.  It seems that the ducky's own vertical offset is high enough to keep the lever from bumping into the brake disc, etc. This was a major question for me, so thanks goes out to meathead.  Beware of these duckies which have the same problem profile as the red ducky (next two pics).   |

|

|

|

« Last Edit: September 06, 2020, 02:17:42 AM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

JimC

|

|

« Reply #21 on: September 04, 2020, 09:54:31 PM » |

|

Ron,

Can you let us know where you bought the black one that works well?

Thanks, Jim

|

|

|

|

|

Logged

Logged

|

Jim Callaghan SE Wisconsin

|

|

|

|

RonW

|

|

« Reply #22 on: September 04, 2020, 10:05:12 PM » |

|

Oh, I only bought the red ducky due to its flat top unaware of said issue. The video in Post 19 discusses the main ducky versions. They're sold on ebay, etc. Btw, I haven't fabricated any ducky lever yet just posted the options.  |

|

|

|

« Last Edit: September 04, 2020, 10:06:54 PM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #23 on: September 05, 2020, 12:00:57 AM » |

|

All good info Ron  For me, the duckhead worked well in the dismount position even though the alignment wasn't what I'd hoped for. It's hard to tell from the pic, but I was able to align the opposite end of the unit up close to the rim. Which cocked out the end in the pic, making the alignment appear worse than it actually was. If the mount end can be "pulled" in and work as well, I'll consider it a success. |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #24 on: September 05, 2020, 12:47:35 AM » |

|

Good job, meathead!

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

pancho

|

|

« Reply #25 on: September 07, 2020, 04:58:04 PM » |

|

Well, you guys have me convinced. I just bought a nylon duckhead to make a mount/dismount bar. I have been doing all my tires (car, truck, bike) for several years now (since I discovered balance beads)

with just an assortment of tire tools and the harbor freight machine. I wanted a good bar for a long time, but just never took the time to search one out. You can use the harbor freight bar on steel rims, but no good for alloy wheels, it would tear them up so it's been all manual with tire tools on the alloy wheels. Looking forward to getting the duckhead.

ANy reason you did not try your bar to mount a tire meathead?

|

|

|

|

|

Logged

Logged

|

The most expensive things you will purchase, are those things you would not have needed if you had listened and obeyed.

|

|

|

|

The emperor has no clothes

|

|

« Reply #26 on: September 07, 2020, 05:06:36 PM » |

|

Well, you guys have me convinced. I just bought a nylon duckhead to make a mount/dismount bar. I have been doing all my tires (car, truck, bike) for several years now (since I discovered balance beads)

with just an assortment of tire tools and the harbor freight machine. I wanted a good bar for a long time, but just never took the time to search one out. You can use the harbor freight bar on steel rims, but no good for alloy wheels, it would tear them up so it's been all manual with tire tools on the alloy wheels. Looking forward to getting the duckhead.

ANy reason you did not try your bar to mount a tire meathead?

I didn't have (or need) a new tire yet. That rear rim is an extra I bought some time back. I could have mounted the old tire back on, but I didn't think about it. |

|

|

|

|

Logged

Logged

|

|

|

|

Skinhead

Member

Posts: 8748

J. A. B. O. A.

Troy, MI

|

|

« Reply #27 on: September 08, 2020, 09:22:49 AM » |

|

I think your issue with the duckbill not seating flush on the room could be solved by having a pivot on the end of the bar where the duckbill mounts. This would allow it to rotate rather than be at a fixed orientation. It should work for the bar on either side of the center bar.

|

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

The emperor has no clothes

|

|

« Reply #28 on: September 08, 2020, 09:27:16 AM » |

|

I think your issue with the duckbill not seating flush on the room could be solved by having a pivot on the end of the bar where the duckbill mounts. This would allow it to rotate rather than be at a fixed orientation. It should work for the bar on either side of the center bar.

I'm not sure I understand. How would you be able to apply leverage on it if it was able to pivot ? |

|

|

|

|

Logged

Logged

|

|

|

|

|

pancho

|

|

« Reply #29 on: September 08, 2020, 11:18:04 AM » |

|

I see what your saying, if the pivot point is directly over the duckhead it seems as if it should work just fine. The head only needs to pivot a few degrees to go to either side, and the tire itself will pull the duckhead against the rim. I will try that out as I build a bar... trouble is all tires on all vehicles are good right now,, even the spare wheels.

Not a problem,, I remember a time when that wasn't the case and it was a problem... I can probably find a wheel to break down to try it out.

|

|

|

|

« Last Edit: September 08, 2020, 11:25:08 AM by pancho »

|

Logged

Logged

|

The most expensive things you will purchase, are those things you would not have needed if you had listened and obeyed.

|

|

|

Skinhead

Member

Posts: 8748

J. A. B. O. A.

Troy, MI

|

|

« Reply #30 on: September 08, 2020, 02:16:54 PM » |

|

I think your issue with the duckbill not seating flush on the room could be solved by having a pivot on the end of the bar where the duckbill mounts. This would allow it to rotate rather than be at a fixed orientation. It should work for the bar on either side of the center bar.

I'm not sure I understand. How would you be able to apply leverage on it if it was able to pivot ? Pancho gets it. |

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

RonW

|

|

« Reply #31 on: September 09, 2020, 12:27:38 AM » |

|

I think your issue with the duckbill not seating flush on the room could be solved by having a pivot on the end of the bar where the duckbill mounts. This would allow it to rotate rather than be at a fixed orientation. It should work for the bar on either side of the center bar.

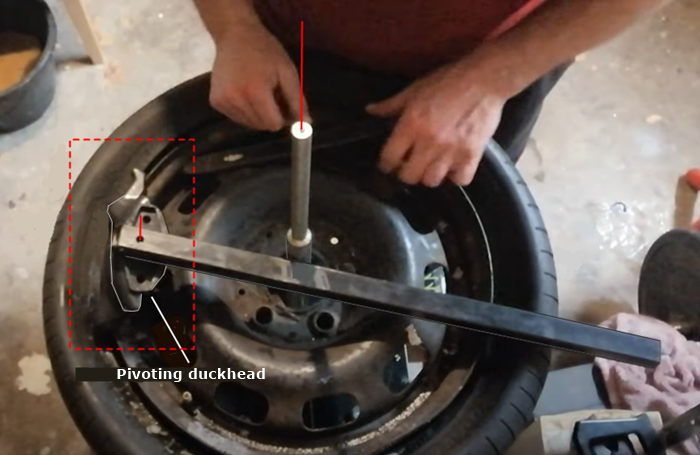

The author of this YouTube video made a pivoting duck head, so judge for yourself (screenshots, below). Btw, the duck head is only rotated counter-clockwise so the lever only sits on that side of the center post. Below, note the duck head isn't square to the lever in their length wise axis. Explains the author here, the angled duck head is to compensate for the lever being rotated around the side of the center post as opposed to the center post being used as an axle for the lever where the duck head would be square to the lever. Of course, that's to make the curve in the duck head concentric to the wheel's circumference.  Only a middle bolt is used giving the duck head a pivot point.  In this situation the black ducky above has the same shape as a red ducky .....  ..... with a bottom lip (A), just that its top isn't flat.  |

|

|

|

« Last Edit: September 09, 2020, 12:10:22 PM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

Mikerthebiker

|

|

« Reply #32 on: September 09, 2020, 09:23:01 PM » |

|

Or......you could remove the pvc pipe, drill a hole in the Center of the angle iron to allow it to fit over the threaded rod. This way, your duck head would be centred and aligned with the rim.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

The emperor has no clothes

|

|

« Reply #33 on: September 09, 2020, 09:37:24 PM » |

|

Or......you could remove the pvc pipe, drill a hole in the Center of the angle iron to allow it to fit over the threaded rod. This way, your duck head would be centred and aligned with the rim.

2 problems with that. Well, actually maybe 3. 1) with the front and rear being 17 and 16 inches, you'd only get it to work on one rim. 2) I think it would weaken the bar significantly. 3) it's the duck head itself that is preventing alignment. The bottom of the duck head bottoms out on the rim before you can align it correctly. 4) the thread rod is used for clamping down the wheel to keep it from turning. I suppose a different clamp system could be configured. It worked very well in the dismount. If it works as well in the mount, it will be a huge step up from using irons. I've thought about grinding down the bottom lip some. But I think Ron is right, it would weaken it too much. |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #34 on: September 10, 2020, 12:18:17 PM » |

|

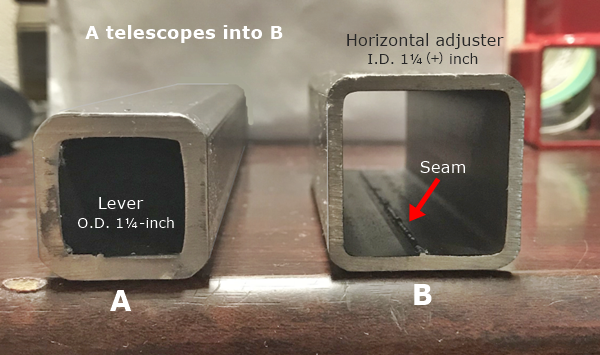

I'm thinkin about going with the design that uses the center post as an axle for the duck head lever. I have another bike with a 19 front and 15 rear, and since the axle design requires a horizontal adjuster, the adjustability would allow the ducky to be used on my other bike as well as the Valk's 16-R and 17-F rims.  Below, the lever telescopes into the horizontal adjuster. The lever is 1¼-inch square tubing (OD) while the ID for the horizontal adjuster is a hair larger than 1¼-inch which should make the lever fit like a glove. I said should because there is an internal seam in the larger square tubing. By chance if you're aware of a method to get rid of the seam, please clue me in. This is my solution or failing that, I'd run a kerf lengthwise on the mating surface.  |

|

|

|

« Last Edit: September 15, 2020, 10:07:03 AM by RonW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The emperor has no clothes

|

|

« Reply #35 on: September 10, 2020, 05:27:44 PM » |

|

If you designed it similar to the pic with the black duck, it would be short enough to get a Dremel in there. I think your idea of adjustability and a centered axle lever is going to work well. I'm really looking forward to seeing it !  |

|

|

|

|

Logged

Logged

|

|

|

|

|