|

old2soon

|

|

« on: January 19, 2012, 11:39:17 AM » |

|

Got mine on the lift for a rear caliper rebuild and lubing the splines. I'm ready to reinstall the wheel and it DO NOT want to seat correctly. It appears to not to be going in all the way. Transmission is in first gear and the 4 bolts for the drive shaft are loose. Wiggled pushed learned a new word or 3 and it still will not go where it belongs. I've searched the board and the answer i need eludes me. Got the 3 new O rings and the thrust washer installed and she be sitting there laughing at me. I hope i'm not the first with this problem. Last march it almost fell together. Any ideas or hints would be appreciated. T I A. RIDE SAFE.

|

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

Daniel Meyer

Member

Posts: 5493

Author. Adventurer. Electrician.

The State of confusion.

|

|

« Reply #1 on: January 19, 2012, 12:03:29 PM » |

|

You sure it's not in all the way? If you are looking at the wheel compared to the black plastic ring on the rear end it will look like it's not in all the way. Basically, if you can get the caliper and spacer in it's in.

Otherwise the only think I can think of is one of your o-rings is too fat (the big one on the star can do this).

|

|

|

|

|

Logged

Logged

|

CUAgain, Daniel Meyer  |

|

|

|

old2soon

|

|

« Reply #2 on: January 19, 2012, 02:05:15 PM » |

|

There in lies the problem Daniel. I can get the spacer or the caliper mount in but NOT both at this point in time. I will check on the O ring you mentioned. Last years was a Carolina Cycle parts and this years is a Honda O E M O ring. When i go out there after our family dinner in about an hour i'll put a Carolina O ring on and see if thats the difference. The rubber flange on the differential is not going or covering the groove. I'll let you know either tonight or tommorrow what i find out. 42 degree weather and 80% humidity and arthritis is not a good combination.  Thanks Daniel-at least now i have something else to check out. RIDE SAFE. |

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

|

SCain

|

|

« Reply #3 on: January 19, 2012, 02:22:04 PM » |

|

Try putting the axle in all the way without the spacer and caliper mount, this might help align everything on the Diff side.

|

|

|

|

|

Logged

Logged

|

Steve  |

|

|

Skinhead

Member

Posts: 8753

J. A. B. O. A.

Troy, MI

|

|

« Reply #4 on: January 19, 2012, 02:25:56 PM » |

|

Check the long spacer that goes into the final drive, make sure it is seated properly.

|

|

|

|

|

Logged

Logged

|

Troy, MI |

|

|

|

RonW

|

|

« Reply #5 on: January 19, 2012, 02:59:34 PM » |

|

If you are looking at the wheel compared to the black plastic ring on the rear end it will look like it's not in all the way.

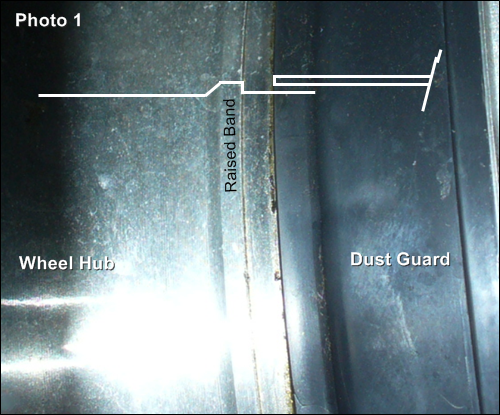

I know this for a fact because one night I spent 2-hours trying to get the dust shield flush with the 'raised band' on the aluminum hub. Fortunately, at some point, I remembered that I had pics taken earlier of the wheel which I was able to reference of. I was thinking the metal collar was crooked.   The rubber flange on the differential is not going or covering the groove.

See pics above .... my dust guard doesn't cover the groove either. It sits a little less than a ¼-inch shy of the 'raised band' on the aluminum hub. I believe this is right. Mr. Meyers?? |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

old2soon

|

|

« Reply #6 on: January 19, 2012, 04:03:45 PM » |

|

Check the long spacer that goes into the final drive, make sure it is seated properly.

I'll look at that other spacer tommorrow and get a better handle on what i'm dealing with. Thanks for the suggestion. RIDE SAFE. |

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

|

old2soon

|

|

« Reply #7 on: January 19, 2012, 04:09:28 PM » |

|

RONW thanks for the pics. Mine are a little further out than your photo. I've got a few things to follow up on now. Like i said in my first post on this subject-last year it almost fell together.  This year it decided to kick my butt.  With all these fine suggestions i should be able to kick its butt tommorrow.  This be one damn fine board.  Thanks to all for the help.  RIDE SAFE. |

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

|

|

|

RonW

|

|

« Reply #9 on: January 19, 2012, 09:36:01 PM » |

|

old2soon .... this must be part of the rites of passage.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

Hook#3287

|

|

« Reply #10 on: January 19, 2012, 09:48:10 PM » |

|

old2soon .... this must be part of the rites of passage. Ain't that the truth! Been there a couple of times. Problem is, it's always months between times of having the wheel off, that I havta relearn the whole dang process again. Old2soon, make sure the flange set is seated correctly. That hung me up once. Putting the axle in as far as the spacer helps to line everything up. I use a car jack to hold the wheel up into position. It gets heavy when it don't want to go together. You'll get it. Good luck. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Ricky-D

|

|

« Reply #11 on: January 20, 2012, 07:48:40 AM » |

|

Using the axle is a time tested help in getting the wheel all lined up and properly seated into the pumpkin.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|

Rio Wil

|

|

« Reply #12 on: January 20, 2012, 08:32:32 AM » |

|

Try installing the drive flange into the final drive splines by its self. See if the big o ring allows the flange to seat properly.....and perhaps you have too much lube in the splines and the o rings won't let enough squeeze out...

|

|

|

|

|

Logged

Logged

|

|

|

|

|

FryeVRCCDS0067

|

|

« Reply #13 on: January 20, 2012, 06:09:40 PM » |

|

You've probably already done this but just in case, you might try putting the bike in gear and rotating the wheel slightly one way or the other in case the splines are not quite lined up.

|

|

|

|

|

Logged

Logged

|

"Extremism in the defense of liberty is no vice. And... moderation in the pursuit of justice is no virtue.'' -- Barry Goldwater, Acceptance Speech at the Republican Convention; 1964  |

|

|

MarkT

Member

Posts: 5196

VRCC #437 "Form follows Function"

Colorado Front Range - elevation 2.005 km

|

|

« Reply #14 on: January 22, 2012, 08:03:18 AM » |

|

You've probably already done this but just in case, you might try putting the bike in gear and rotating the wheel slightly one way or the other in case the splines are not quite lined up.

Just wrestled with this again a couple days ago. A problem was holding the wheel / swingarm up to get the axle high enough to clear the exhaust with out holding it with a jack under the tire, so I could move the wheel around to get the splines inside to line up, and be able to move the axle in & out - I found as others have mentioned, it helps to get the axle inserted all the way to the other swingarm axle hole without the spacer in, so the axle will be properly aligned, so the bearings don't bind and the wheel is free to move laterally. So I lifted the tire with the floor jack, then used a bar clamp spanning the left side swingarm and the upper shock mount, to hold the swingarm up, then lowered the floor jack then I could manipulate the wheel and axle to get them lined up and the wheel fully seated. I convinced the wheel to move right with the help if a large lever - which was a large tire iron I had picked up at Harbor Freight. Worked like a charm. |

|

|

|

|

Logged

Logged

|

|

|

|

|

old2soon

|

|

« Reply #15 on: January 31, 2012, 05:33:19 PM » |

|

You've probably already done this but just in case, you might try putting the bike in gear and rotating the wheel slightly one way or the other in case the splines are not quite lined up.

Just wrestled with this again a couple days ago. A problem was holding the wheel / swingarm up to get the axle high enough to clear the exhaust with out holding it with a jack under the tire, so I could move the wheel around to get the splines inside to line up, and be able to move the axle in & out - I found as others have mentioned, it helps to get the axle inserted all the way to the other swingarm axle hole without the spacer in, so the axle will be properly aligned, so the bearings don't bind and the wheel is free to move laterally. So I lifted the tire with the floor jack, then used a bar clamp spanning the left side swingarm and the upper shock mount, to hold the swingarm up, then lowered the floor jack then I could manipulate the wheel and axle to get them lined up and the wheel fully seated. I convinced the wheel to move right with the help if a large lever - which was a large tire iron I had picked up at Harbor Freight. Worked like a charm. To any and all that replied with the wisdom gained from been there done that.  Suspending the swing arm was/is the trick.  Getting the jack out from under the tire and coming up with another third hand is key.  My solution to the problem was to take a 1 inch rartchet strap to both sides of the swingarm.  I have some old padded fender covers that protected the rear fender rather nicely. The hooks on the ratchet straps are covered in heavy duty vinyl. On the differential side i put a hook into the lower shock bolt hole. On the brake side i hooked the strap back to itself with the hook around the swingarm. With the wheel up in the fender draw tension on the ratchet strap lower jack and stabbed the wheel in EXACTLY where it needed to be.  Only reason i'm just getting done-arthritis and cold damp weather NOT a good combination.  Again-thanks to everbody that helped and B T W this board ROCKS.  RIDE SAFE. |

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

|