|

dr.danh

|

|

« on: July 01, 2015, 07:09:28 PM » |

|

My front brakes are wore and will be replacing them. Ques. Once the brake calipers are applied what relieves the pads off the disc. Just the lack of the hydr. pressure? If caliper pistons are sticking then the pads wouldn't go back into place. And cause excessive pad wear. Correct? Any easy way to pull the pistons and sand then with seals?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

matt

|

|

« Reply #1 on: July 01, 2015, 07:58:02 PM » |

|

Yup when you release brake tgere is a square cut seal that will bring piston back just a little so brakes release. If you use search you will find answers for rebuilding. Things needed compressor, block of wood, new seals and brake fluid

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #2 on: July 01, 2015, 11:12:41 PM » |

|

Ques. Once the brake calipers are applied what relieves the pads off the disc. Just the lack of the hydr. pressure?

Affirmative, after the hydraulic pressure is released, the spinning rotor nudges the pads a mm away from the rotor's surface. Not like drum brakes which have a return spring to retract the brake shoe away from the drum. If caliper pistons are sticking then the pads wouldn't go back into place. And cause excessive pad wear. Correct? - Any easy way to pull the pistons and sand then with seals?

I'd stay away from pulling them pistons fully out from their bores .... just to clean them up. A better option is to place a paint stick etc. between the old pads and apply the brakes. This should push the pistons just enough out of their bores to expose any hidden grit that needs cleaning. You can clean the ring around the collar on the pistons with a strip of cloth or strip of fine sandpaper wrapped around the pistons. |

|

|

|

« Last Edit: July 01, 2015, 11:37:25 PM by RONW »

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

hubcapsc

Member

Posts: 16816

upstate

South Carolina

|

|

« Reply #3 on: July 02, 2015, 03:00:01 AM » |

|

Ques. Once the brake calipers are applied what relieves the pads off the disc. Just the lack of the hydr. pressure?

Affirmative, after the hydraulic pressure is released, the spinning rotor nudges the pads a mm away from the rotor's surface. Not like drum brakes which have a return spring to retract the brake shoe away from the drum. If caliper pistons are sticking then the pads wouldn't go back into place. And cause excessive pad wear. Correct? - Any easy way to pull the pistons and sand then with seals?

I'd stay away from pulling them pistons fully out from their bores .... just to clean them up. A better option is to place a paint stick etc. between the old pads and apply the brakes. This should push the pistons just enough out of their bores to expose any hidden grit that needs cleaning. You can clean the ring around the collar on the pistons with a strip of cloth or strip of fine sandpaper wrapped around the pistons. I've taken my calipers apart any number of times. The brakes are real nice with the calipers/pistons all cleaned up, pins greased, new pads... I've thought about Ronw's short cut several times, and I bet it would pretty much get you the same thing... as long as you can push the pistons out far enough to get to the entire "ring around the collar"... I think this picture would be "not far enough"...  -Mike |

|

|

|

|

Logged

Logged

|

|

|

|

|

Hook#3287

|

|

« Reply #4 on: July 02, 2015, 03:42:24 AM » |

|

I would do as Ronw suggested now and rebuild them completely this winter.

Nothing like freshly rebuilt calipers, makes you realize how bad they were.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #5 on: July 02, 2015, 01:47:32 PM » |

|

hubcapsc, if memory serves I got the paint stick idea from an earlier post of yours. I think was yours was accompanied with a pic. Also, I'm thinking about using an internal plumbing wrench to rotate the pistons. If I ever find where I put it, but I do have it somewhere. I ain't buying another one. *Pulling the piston is definitely the better way to go, but I have nightmares big time about getting all the bubbles out of the brake line. Probably take longer than putting back the bolts on the rear fender siderails, until you know the trick of course accordingly.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

Cliff

|

|

« Reply #6 on: July 03, 2015, 05:54:43 AM » |

|

hubcapsc, if memory serves I got the paint stick idea from an earlier post of yours. I think was yours was accompanied with a pic. Also, I'm thinking about using an internal plumbing wrench to rotate the pistons. If I ever find where I put it, but I do have it somewhere. I ain't buying another one. *Pulling the piston is definitely the better way to go, but I have nightmares big time about getting all the bubbles out of the brake line. Probably take longer than putting back the bolts on the rear fender siderails, until you know the trick of course accordingly.  What is the diameter of internal plumbing wrench needed? |

|

|

|

|

Logged

Logged

|

VRCC # 29680

|

|

|

|

WintrSol

|

|

« Reply #7 on: July 03, 2015, 07:34:23 AM » |

|

I wouldn't use any grit of sandpaper - not only does it remove the polish from the surface, those fine scratches are a good place to start a leak. A strip of denim soaked in brake fluid or brake system cleaner works well enough for me.

|

|

|

|

|

Logged

Logged

|

98 Honda Valkyrie GL1500CT Tourer

Photo of my FIL Jack, in honor of his WWII service

|

|

|

|

Dorkman

|

|

« Reply #8 on: July 09, 2015, 10:45:29 PM » |

|

Another method: Soak a shoelace in brake cleaner, then buff around the piston like you're doin' your shoes. I would also stay away from fine sandpaper . . . you may take off a bit too much.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #9 on: July 10, 2015, 02:38:55 AM » |

|

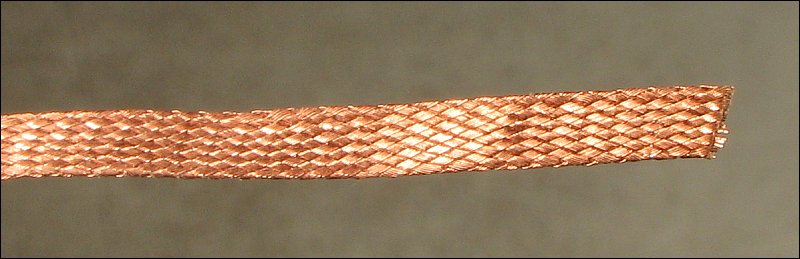

Excellent idea! The strips of cloth that I've been using worked better if the fabric material does not have a tendency to stretch a lot. As the material stretches the width becomes too narrow and the flat strips start to become round like a cord, same with the flat shoelaces if they're the elastic type, I would think. And, okay then, sandpaper isn't the best material. Many years of repeated sanding is bound to undersize the OD of the piston and so on & replacement Oem pistons are $20 each yikes. Any thoughts on using braided de-soldering wicks.   What is the diameter of internal plumbing wrench needed?  I don't know. I was merely thinking out loud but thanks the same for listening. |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

BigBod

|

|

« Reply #10 on: July 10, 2015, 02:54:51 AM » |

|

Go ahead and pull the pistons out completely. Replace both seals in the calliper. Most importantly, clean the recess where the seals sit. 9 times out of 10 it is the corrosion in the recess that forces the seals out of place and make the piston stick.

Best thing I have found to clean the recess is a dremmel with the small wire brush wheel attached, works a treat.

As for the pistons, polish them up on a polishing wheel. Don't know if you can get them over there, but here we can buy aftermarket pistons in stainless steel.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #11 on: July 10, 2015, 03:01:56 AM » |

|

How difficult is it to get all the bubbles outta the brake lines? (after complete disassembly)

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

Jess from VA

|

|

« Reply #12 on: July 10, 2015, 08:32:15 AM » |

|

I get the pistons almost but not completely out. I then use a pistol cleaning rod with brass/stainless brushes and bore solvents ( Hoppes, Shooter's Choice). You can access every nook and cranny, and my brakes are spotless when done. Blow crud out with brake cleaner spray.   |

|

|

|

|

Logged

Logged

|

|

|

|

gordonv

Member

Posts: 5766

VRCC # 31419

Richmond BC

|

|

« Reply #13 on: July 10, 2015, 10:44:47 PM » |

|

Wow, I would hate to see how/what you do to clean your guns!  |

|

|

|

|

Logged

Logged

|

1999 Black with custom paint IS   |

|

|

|

RonW

|

|

« Reply #14 on: July 11, 2015, 05:14:48 PM » |

|

hmmmm, I always thought of a bike as being a loaded gun.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

BigBod

|

|

« Reply #15 on: July 15, 2015, 07:45:06 AM » |

|

How difficult is it to get all the bubbles outta the brake lines? (after complete disassembly)

It really isn't that bad, much easier with 2 people. If you get to a point where it's almost done but still a bit soft...if it's the front brake, tie the lever hard against the bars and turn the bars so the fluid reservoir is at it's highest point, chances are all the bubble will rise up over night...when you untie the next day will probably be perfect.. You can do the same with the rear to a certain extent, jam a bit of wood on the brake pedal and under the bars... |

|

|

|

|

Logged

Logged

|

|

|

|

|

BigBod

|

|

« Reply #16 on: July 15, 2015, 07:46:54 AM » |

|

I get the pistons almost but not completely out. I then use a pistol cleaning rod with brass/stainless brushes and bore solvents ( Hoppes, Shooter's Choice). You can access every nook and cranny, and my brakes are spotless when done. Blow crud out with brake cleaner spray.   Waste of time if you've got crud behind the seals. The only way to do it properly is to remove the pistons completely. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Paladin528

|

|

« Reply #17 on: July 15, 2015, 08:09:50 AM » |

|

If you pull the pistons out you should get a brake bore hone and hone the bores out. This will make sure the bore is clean and allow the seals to do their job.

The piston itself has no sealing or contact properties to the bore, it is the rubber that is doing all the work.

I would say break em down, clean the crap out of them, Hone the bores, new seals, grease the pins, put new pads on and reinstall em.

Then the fun of bleeding them. Pressure bleeder or speed bleeders are your friend here.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Jess from VA

|

|

« Reply #18 on: July 15, 2015, 09:29:51 AM » |

|

Waste of time if you've got crud behind the seals.

I guess I don't because my brakes are perfect and responsive.... and squeaky clean.

|

|

|

|

|

Logged

Logged

|

|

|

|

|