|

..

|

|

« on: November 10, 2015, 12:14:18 PM » |

|

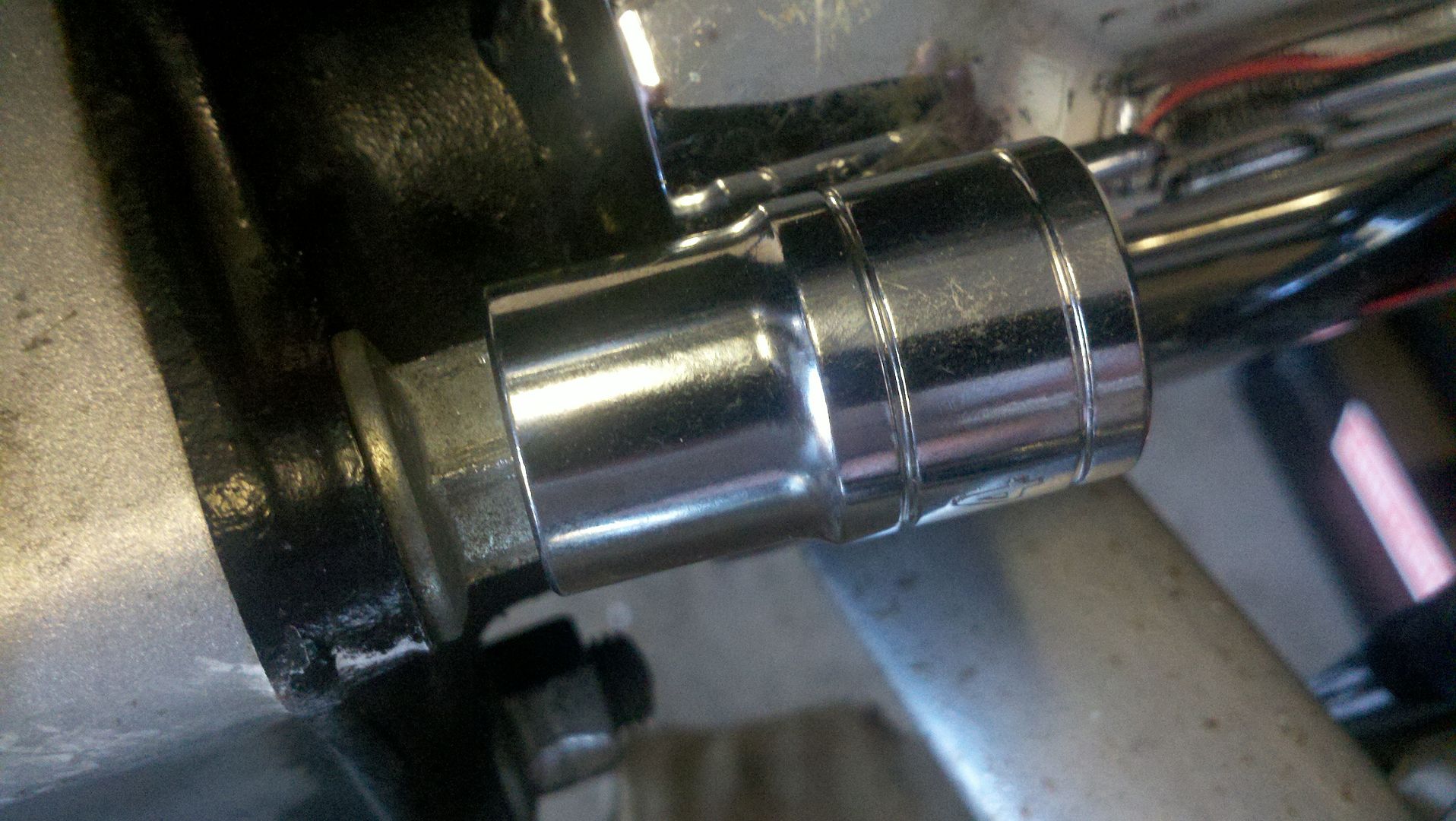

Final drive That's just really - insert choice curse word - stupid.  Add the width of the ratchet and it's even more ridiculous. |

|

|

|

|

Logged

Logged

|

|

|

|

|

six2go #152

|

|

« Reply #1 on: November 10, 2015, 12:20:02 PM » |

|

Box end wrench?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

..

|

|

« Reply #2 on: November 10, 2015, 12:25:13 PM » |

|

Had house fire don't have one to hand.

Off to Pepboys again.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

..

|

|

« Reply #3 on: November 10, 2015, 12:28:48 PM » |

|

Box end wrench?

PS How do I get a f'in torque wrench on the darn thing??? |

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #4 on: November 10, 2015, 12:42:51 PM » |

|

You must remove the chrome swingarm cover, then all will be gravey

|

|

|

|

|

Logged

Logged

|

|

|

|

|

old2soon

|

|

« Reply #5 on: November 10, 2015, 12:44:34 PM » |

|

H/F has a handy dandy selection of extensions the call a wobble extension or some such. The set I bought had varying lengths in 1/4 3/8 and 1/2 inch drive. Really quite helpful in your particular situation. RIDE SAFE.

|

|

|

|

|

Logged

Logged

|

Today is the tommorow you worried about yesterday. If at first you don't succeed screw it-save it for nite check. 1964 1968 U S Navy. Two cruises off Nam.

VRCCDS0240 2012 GL1800 Gold Wing Motor Trike conversion

|

|

|

Gavin_Sons

Member

Posts: 7109

VRCC# 32796

columbus indiana

|

|

« Reply #6 on: November 10, 2015, 01:31:41 PM » |

|

Yep wobble sockets, who uses a torque wrench? A 4 foot pipe on the end of your ratchet is all you need  |

|

|

|

|

Logged

Logged

|

|

|

|

|

|

|

..

|

|

« Reply #8 on: November 10, 2015, 01:36:20 PM » |

|

You must remove the chrome swingarm cover, then all will be gravey

Really? How the blistering barnacles does that come off?  I've finagled the pumpkin off. All is well at this end of the drive. Now to work out how to get at the end tucked away out of sight. Oh joy. Previous owner had chewed up one of the nut heads as well.  Back to the parts fiche. Once I put the drive shaft back in the pumpkin. I followed BIGBF's easy technique. Should there be a little in and out play? |

|

|

|

|

Logged

Logged

|

|

|

|

Gavin_Sons

Member

Posts: 7109

VRCC# 32796

columbus indiana

|

|

« Reply #9 on: November 10, 2015, 01:55:13 PM » |

|

Yes, maybe a 1/16" of play is normal

|

|

|

|

|

Logged

Logged

|

|

|

|

fudgie

Member

Posts: 10652

Better to be judged by 12, then carried by 6.

Huntington Indiana

|

|

« Reply #10 on: November 10, 2015, 02:12:56 PM » |

|

Yes, maybe a 1/16" of play is normal

Is that what you tell Kelli?  |

|

|

|

|

Logged

Logged

|

Now you're in the world of the wolves... And we welcome all you sheep... VRCC-#7196 VRCCDS-#0175 DTR PGR |

|

|

|

..

|

|

« Reply #11 on: November 10, 2015, 03:10:05 PM » |

|

Yes, maybe a 1/16" of play is normal

BIGBF confirmed as well. Thanks. |

|

|

|

|

Logged

Logged

|

|

|

|

|

The emperor has no clothes

|

|

« Reply #12 on: November 10, 2015, 04:43:05 PM » |

|

You must remove the chrome swingarm cover, then all will be gravey

Do you mean the chrome driveshaft cover ? I don't have one and there are still 2 of the nuts I can't get my ratchet & socket on. I've just been using a box end on those 2. |

|

|

|

|

Logged

Logged

|

|

|

|

|

..

|

|

« Reply #13 on: November 10, 2015, 06:05:20 PM » |

|

You must remove the chrome swingarm cover, then all will be gravey

Do you mean the chrome driveshaft cover ? I don't have one and there are still 2 of the nuts I can't get my ratchet & socket on. I've just been using a box end on those 2. Yep. So much for a torque wrench. |

|

|

|

|

Logged

Logged

|

|

|

|

|

mark81

|

|

« Reply #14 on: November 10, 2015, 06:05:28 PM » |

|

|

|

|

|

|

Logged

Logged

|

1997 Honda Valkyrie 1981 Honda CB750 Custom  |

|

|

|

Bagger John - #3785

|

|

« Reply #15 on: November 11, 2015, 07:25:28 AM » |

|

You must remove the chrome swingarm cover, then all will be gravey Do you mean the chrome driveshaft cover ? Really? How the blistering barnacles does that come off?  It's held on by a couple of 5/16" wide zip ties. Look underneath the swingarm and they will be visible. Cut them and off the cover will come. I don't have one and there are still 2 of the nuts I can't get my ratchet & socket on. I've just been using a box end on those 2.

My favorite tool for those nuts is a mid-depth 6pt Crasftsman 3/8"dr x 14mm socket. The two hard-to-get-at ones are accessed with a box end wrench for loosening then a set of extensions, the socket and a torque wrench for tightening. Sadly, Craftsman discontinued those sockets but they can be found used. Most of the tool truck brands still list new sets, however. |

|

|

|

|

Logged

Logged

|

|

|

|

Gryphon Rider

Member

Posts: 5234

2000 Tourer

Calgary, Alberta

|

|

« Reply #16 on: November 11, 2015, 10:48:30 AM » |

|

I use a click-type torque wrench on the nuts that it can be used for. I think I use a U-joint with it. I don't use the proper handle, but place my hand on the shaft at the same distance from the drive end as the length of my box-end wrench. This gives me a feel for the proper pressure to use on the end of the wrench when I need to use it for the back 1 or 2 nuts.

|

|

|

|

|

Logged

Logged

|

|

|

|

MarkT

Member

Posts: 5196

VRCC #437 "Form follows Function"

Colorado Front Range - elevation 2.005 km

|

|

« Reply #17 on: November 11, 2015, 04:56:33 PM » |

|

In your pic - looks like 1/2" drive socket. Both my 1/2" drive and 3/8" drive sockets fit on those 14mm nuts. Yours must be really thickwall sockets. Go to a 3/8 drive, you should get enough clearance. Also, if your torque wrench is too big, get a reducer down to 3/8 or 1/4 drive and use extensions to back it off a little. As for me - I use 1/4 drive most of the time - fits in smaller places, and my 1/4 drive sockets go up to 14mm. +1 on the wobble drive extensions - use them frequently in tight spots.

|

|

|

|

« Last Edit: November 11, 2015, 05:06:51 PM by MarkT »

|

Logged

Logged

|

|

|

|

|

DK

|

|

« Reply #18 on: November 11, 2015, 05:58:21 PM » |

|

You must remove the chrome swingarm cover, then all will be gravey

Do you mean the chrome driveshaft cover ? I don't have one and there are still 2 of the nuts I can't get my ratchet & socket on. I've just been using a box end on those 2. Yep. So much for a torque wrench. Get a crowfoot to use with the torque wrench. Dan |

|

|

|

|

Logged

Logged

|

Machinery has a mysterious soul and a mind of its own.

|

|

|

|

Bigwolf

|

|

« Reply #19 on: November 11, 2015, 10:35:51 PM » |

|

You must remove the chrome swingarm cover, then all will be gravey

Do you mean the chrome driveshaft cover ? I don't have one and there are still 2 of the nuts I can't get my ratchet & socket on. I've just been using a box end on those 2. Yep. So much for a torque wrench. I do not have a chrome swing arm cover so maybe that is the difference. I use a Proto click style 1/2 inch drive torque wrench on 3 of those 4 bolts and I do so without using an extension. It is tedious work. Also, since I use a 6 point socket, I do have to take the socket off the wrench turn it 90 degrees and put it back on the wrench several times before I finish. For taking those nuts off and for snugging them down I use a ratcheting box end wrench. I believe, as others have said, a wobble extension would be a good way to get the job done. |

|

|

|

|

Logged

Logged

|

|

|

|

O-B-1

Member

Posts: 222

Show ain't over until the Fat Lady sings

Vancouver, WA

|

|

« Reply #20 on: November 16, 2015, 12:17:46 PM » |

|

Yes, maybe a 1/16" of play is normal

Is that what you tell Kelli?  Check it out on Snopes, it's not the LENGTH, it's the girth that counts... Bwahahahahaha |

|

|

|

|

Logged

Logged

|

David W. Mitchell

1999 Honda Valkyrie GL1500C

|

|

|

|

Carl

|

|

« Reply #21 on: November 16, 2015, 09:58:22 PM » |

|

I often use the crowfeet extensions when torquing different fasteners. Be sure to calculate the proper torque setting for the extension.

Torque Setting = Desired Torque X Wrench Length / (Wrench Length + Extension Length). An extension will decrease the torque setting.

I occasionally have customers come in asking why our bolts keep snapping. First thing I do is ask what torque they are applying and by what method.

It may not make a lot of difference on most of the fasteners on our bikes, but better safe than sorry.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

indybobm

|

|

« Reply #22 on: November 17, 2015, 04:50:31 AM » |

|

Correct me if I am wrong, (cannot imagine that on this site), but I think that it is best to use the smallest torque wrench that will handle the torque required.

For example, if you have a nut that requires 16 ftlbs and you use a 1/2" torques wrench that is capable of 150 ftlbs, it will not be as accurate at 16 ftlbs as a smaller torque wrench that has a capacity of 80 ftlbs.

Use the smallest one that will get the job done. I have three torque wrenches, 1/2", 3/8", and 1/4".

Also, when you are through using the torque wrench, always run the setting back down to zero. If left at 67 ftlbs for example, the accuracy will degrade over time.

|

|

|

|

« Last Edit: November 17, 2015, 05:13:29 AM by indybobm »

|

Logged

Logged

|

So many roads, so little time

VRCC # 5258

|

|

|

|

Carl

|

|

« Reply #23 on: November 17, 2015, 07:52:01 AM » |

|

Indybobm, you are correct, but I would add that you need to use the smallest units possible. In/lbs vs. ft/lbs. Always use the smallest unit available. The problems we've seen are at the lower end of the scale. Accuracy is not as good when using the minimum measures.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Paladin528

|

|

« Reply #24 on: November 17, 2015, 10:12:53 AM » |

|

The lower 10% of the torque wrench is not very accurate at all. Always use a wrench that puts the torque setting near the middle or upper end of the scale.

As for which one to use. As long as the above condition is met, Torque is torque.

|

|

|

|

|

Logged

Logged

|

|

|

|

|