|

Bronxboy

|

|

« on: July 26, 2016, 04:08:23 PM » |

|

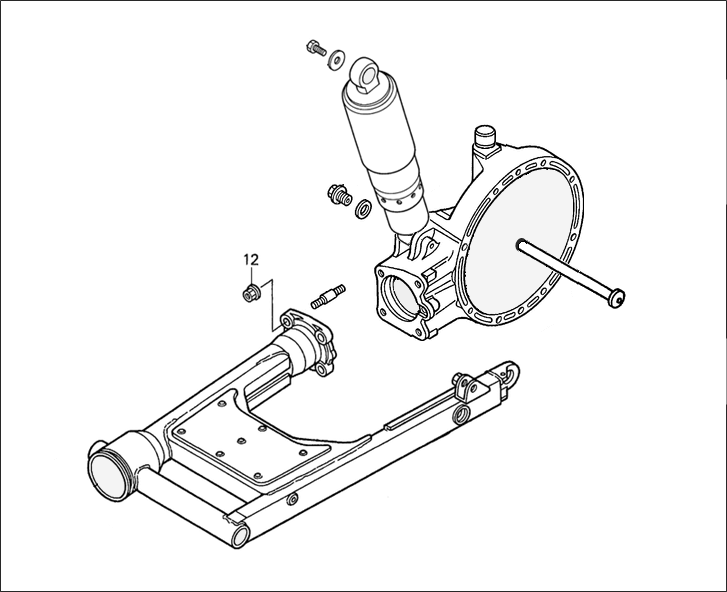

Got everything out and ready for grease. I have 72,000 miles on the bike and me and my buddy Gil think they are about 50% worn, Putting a few pictures up for the Guru's out there for there opinion. Someone also said that the Moly Paste I have been using may have contributed to premature wear? The funny thing was that when I went to Honda for my Orings and Thrust Washers I was going to pick up more grease. The guy at the parts counter said that they discontinued carrying the Moly and they recommend a different grease now? So there may be something to it?     |

|

|

|

|

Logged

Logged

|

|

|

|

|

Grumpy

|

|

« Reply #1 on: July 26, 2016, 04:56:57 PM » |

|

I cannot say any thing bad about the moly from honda, these are my splines at 76,000   I agree also, yours are on the down hill side. Quite a lot of wear there. |

|

|

|

|

Logged

Logged

|

Life is like a hot bath. It feels good while you’re in it, but the longer you stay in, the more wrinkled you get. |

|

|

|

Bronxboy

|

|

« Reply #2 on: July 26, 2016, 05:25:29 PM » |

|

Hey Grumpy, keep an eye out for me on a new set of splines, actually a whole drivetrain is probably needed soon. Gil said that they can press a New Goldwing spline into the case?

|

|

|

|

|

Logged

Logged

|

|

|

|

John Schmidt

Member

Posts: 15372

a/k/a Stuffy. '99 I/S Valk Roadsmith Trike

De Pere, WI (Green Bay)

|

|

« Reply #3 on: July 26, 2016, 05:34:56 PM » |

|

Yup, sure can. Bill did it for me so I'd have a spare final drive. The Goldwing final I picked up off Ebay was something like $25, maybe a bit more but still cheaper than rebuilding with Honda parts. My splines look like Bill's, I use the Honda moly and mix with high pressure grease also with moly content. Just stir it up in my palm while wearing rubber gloves, then schmooie (technical term) it on the splines. So far so good.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #4 on: July 26, 2016, 05:45:47 PM » |

|

Bronxboy, I agree with the 50% warn assessment, you are smart to look for new, the second half will surely wear faster than the first. One question, why is there a nut missing from the flange? You never mess with them

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #5 on: July 26, 2016, 06:07:48 PM » |

|

Bronxboy, I agree with the 50% warn assessment, you are smart to look for new, the second half will surely wear faster than the first. One question, why is there a nut missing from the flange? You never mess with them

A couple of them were a little loose, so I am going to clean the threads and re apply some locktite Good eye, we are all Valkaholics  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #6 on: July 26, 2016, 06:14:12 PM » |

|

I should be good until the next service, so I will deal with it in 20K miles or so. The way we ride, that's just around the corner  |

|

|

|

|

Logged

Logged

|

|

|

|

h13man

Member

Posts: 1892

To everything there is an exception.

Indiana NW Central Flatlands

|

|

« Reply #7 on: July 26, 2016, 06:17:48 PM » |

|

Honda Moly 60 has been used for years w/o failure to my knowledge but... M77 is the replacement. Cost more and 3/8 oz. less. I recently bought up the last of Moly 60 from a dealer and shared with some other shaftie riders.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

F6Dave

|

|

« Reply #8 on: July 26, 2016, 07:15:33 PM » |

|

Your pinion gear looks great. That's where the lube really matters. In theory, it's supposed to be lubed by gear oil fed from the final drive by a tiny hole. That doesn't always work, so there's another school of thought I learned from a Honda service manager years ago: pack the pinion cup with as much grease as you can get in there. I've used that method and the pinion gears and cups have lasted 175K on one Valk and 97K on the other.

The drive splines are another story. On mine, I used some Valvoline multi purpose grease from a can I bought in the 70s until it ran out a few years ago. Now I use plain old wheel bearing grease, and the splines in the flange and drive still look like new on both bikes. You could probably get away with using WD-40.

What wears out the drive splines is misalignment. There's a lot of slop in the 4 holes in the driveshaft tube, so if you tighten those nuts first, it's likely that the wheel flange won't be perfectly parallel to the face of the final drive, which means the splines will not mate squarely. That essentially forces the splines to function like a U-joint, grinding away at each other with every turn of the wheel. When that happens they'll wear down quickly regardless of the grease you use.

The simple solution is to torque down the axle nut BEFORE tightening those 4 nuts. That aligns the splines, resulting in virtually no movement, and no wear. The grease doesn't matter that much. I've seen dry, rusty splines that showed no wear because they were aligned properly.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #9 on: July 26, 2016, 07:35:49 PM » |

|

Your pinion gear looks great. That's where the lube really matters. In theory, it's supposed to be lubed by gear oil fed from the final drive by a tiny hole. That doesn't always work, so there's another school of thought I learned from a Honda service manager years ago: pack the pinion cup with as much grease as you can get in there. I've used that method and the pinion gears and cups have lasted 175K on one Valk and 97K on the other.

The drive splines are another story. On mine, I used some Valvoline multi purpose grease from a can I bought in the 70s until it ran out a few years ago. Now I use plain old wheel bearing grease, and the splines in the flange and drive still look like new on both bikes. You could probably get away with using WD-40.

What wears out the drive splines is misalignment. There's a lot of slop in the 4 holes in the driveshaft tube, so if you tighten those nuts first, it's likely that the wheel flange won't be perfectly parallel to the face of the final drive, which means the splines will not mate squarely. That essentially forces the splines to function like a U-joint, grinding away at each other with every turn of the wheel. When that happens they'll wear down quickly regardless of the grease you use.

The simple solution is to torque down the axle nut BEFORE tightening those 4 nuts. That aligns the splines, resulting in virtually no movement, and no wear. The grease doesn't matter that much. I've seen dry, rusty splines that showed no wear because they were aligned properly.

U are right about the weap hole, I always use a lot of grease in those areas. And yes after having 4 valks over the years u learn all the tricks of this great forum. The last thing I tighten are the 4 bolts so that is a non issue. At this point I have no vibrations and she rides smooth as silk, I will deal with it at the next service. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #10 on: July 26, 2016, 08:16:01 PM » |

|

The last thing I tighten are the 4 bolts As long as last doest mean LAST like after the shocks get put back on and the bike gets lowered to the ground, that would severely interfere with final drive alignment. Last should mean IMMEDIATELY after torquing of the axle. |

|

|

|

|

Logged

Logged

|

|

|

|

|

The emperor has no clothes

|

|

« Reply #11 on: July 26, 2016, 08:55:37 PM » |

|

The last thing I tighten are the 4 bolts As long as last doest mean LAST like after the shocks get put back on and the bike gets lowered to the ground, that would severely interfere with final drive alignment. Last should mean IMMEDIATELY after torquing of the axle. I am a little confused. Once you tighten the axle how would the alignment get thrown off by mounting the shocks or lowering the wheel ? I always thought the important thing was to tighten the axle first before the 4 pumpkin nuts. |

|

|

|

|

Logged

Logged

|

|

|

|

|

RonW

|

|

« Reply #12 on: July 27, 2016, 03:06:11 AM » |

|

The pumpkin and swingarm was always meant to work as a single unit. If they're disjointed, the shock will tilt the pumpkin out of alignment to the swingarm. The rear shock will push or pull on the pumpkin causing the pumpkin to rotate around the axle (see graphic, below). The shocks might even keep the pumpkin from aligning with the swingarm, perhaps just a few degrees, but that's all it takes to screw up the internals. Yea, torquing the 4 bolts to specs should re-adjust things back in place. It's just a safer sequence tightening the 4 bolts immediately after the axle.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

indybobm

|

|

« Reply #13 on: July 27, 2016, 04:51:50 AM » |

|

I think the Final Drive Splines are serviceable if greased/maintained properly. The Drive Flange however is another story. I would look for a useable used Drive Flange to get me to the next maintenance cycle. You probably realize this but you do not/should not remove the nuts from the pins on the Drive Flange.

|

|

|

|

|

Logged

Logged

|

So many roads, so little time

VRCC # 5258

|

|

|

|

Chrisj CMA

|

|

« Reply #14 on: July 27, 2016, 05:03:55 AM » |

|

The last thing I tighten are the 4 bolts As long as last doest mean LAST like after the shocks get put back on and the bike gets lowered to the ground, that would severely interfere with final drive alignment. Last should mean IMMEDIATELY after torquing of the axle. I am a little confused. Once you tighten the axle how would the alignment get thrown off by mounting the shocks or lowering the wheel ? I always thought the important thing was to tighten the axle first before the 4 pumpkin nuts. It's all important, or plan on buying more drive train parts |

|

|

|

|

Logged

Logged

|

|

|

|

|

F6Dave

|

|

« Reply #15 on: July 27, 2016, 06:52:40 AM » |

|

I love my 2 Valkyries. They're some of the finest motorcycles ever built. I'll probably never sell them.

But reading all of this makes me like my new F6B even more. Pop off the rear fender (4 screws and a plug), slide out the audio amp (4 bolts and a plug), then remove 5 lug nuts and the wheel rolls out the back of the bike. Maybe a 10 minute job. I bought a brand new spare wheel and tire (for $200!) from a trike builder so now I can have a tire ready to go, and do the complete swap in less than a half hour. Leaves more time for riding!

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #16 on: July 27, 2016, 01:46:33 PM » |

|

I love my 2 Valkyries. They're some of the finest motorcycles ever built. I'll probably never sell them.

But reading all of this makes me like my new F6B even more. Pop off the rear fender (4 screws and a plug), slide out the audio amp (4 bolts and a plug), then remove 5 lug nuts and the wheel rolls out the back of the bike. Maybe a 10 minute job. I bought a brand new spare wheel and tire (for $200!) from a trike builder so now I can have a tire ready to go, and do the complete swap in less than a half hour. Leaves more time for riding!

What fun is that  I actually enjoy doing it, and knowing it was done right. It seems to get easier each time it is done. I spoke to the Honda Dealer and he said that the flange is still available for $200. So I already ordered New Dampners for the next service and If I don't find a good used one by the next service, I will buy a new one and have a new spline pressed into the pumpkin. |

|

|

|

« Last Edit: July 28, 2016, 06:07:12 AM by Bronxboy »

|

Logged

Logged

|

|

|

|

|

indybobm

|

|

« Reply #17 on: July 27, 2016, 06:46:42 PM » |

|

If you go the GW1500 drive spline route, make sure that the GW1500 final drive has good splines AND comes with the matching drive flange that it has spent it's life with (existing wear pattern). Also plan on using the Valk ring gear bearing and shim (between the ring gear and bearing). This helps keep the back lash proper.

|

|

|

|

« Last Edit: July 27, 2016, 07:16:33 PM by indybobm »

|

Logged

Logged

|

So many roads, so little time

VRCC # 5258

|

|

|

|

billyboy

|

|

« Reply #18 on: July 28, 2016, 03:34:42 PM » |

|

so should I tighten the 4 bolts when I let it down off the jack or on it

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #19 on: July 28, 2016, 04:40:31 PM » |

|

so should I tighten the 4 bolts when I let it down off the jack or on it

I tighten the axel bolt first while the wheel is down, then tighten the 4 bolts. Where the hell have u been stranger?  |

|

|

|

|

Logged

Logged

|

|

|

|

|

The emperor has no clothes

|

|

« Reply #20 on: July 28, 2016, 04:51:01 PM » |

|

so should I tighten the 4 bolts when I let it down off the jack or on it

I tighten the axel bolt first while the wheel is down, then tighten the 4 bolts. Where the hell have u been stranger?  I tighten the axle with it still up in the air. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #21 on: July 28, 2016, 08:39:37 PM » |

|

so should I tighten the 4 bolts when I let it down off the jack or on it

I tighten the axel bolt first while the wheel is down, then tighten the 4 bolts. Where the hell have u been stranger?  I tighten the axle with it still up in the air. I don't let it all the way down, just let the tire hit the floor |

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #22 on: July 29, 2016, 05:05:39 AM » |

|

so should I tighten the 4 bolts when I let it down off the jack or on it

I tighten the axel bolt first while the wheel is down, then tighten the 4 bolts. Where the hell have u been stranger?  I tighten the axle with it still up in the air. I don't let it all the way down, just let the tire hit the floor If you tightened the axle and the four bolts with the tire touching the ground you run the risk that true alignment of the wheel to the final drive may be prevented. |

|

|

|

« Last Edit: July 29, 2016, 05:08:18 AM by Chrisj CMA »

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #23 on: July 29, 2016, 07:00:27 AM » |

|

Well I ran her down the road at hwy speeds and above, all good in the hood. I also did brakes front and rear, new tires, clutch & brake fluid flush, oil change, new gear oil in the rear, it's like riding on a New Machine  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Chrisj CMA

|

|

« Reply #24 on: July 29, 2016, 07:40:50 AM » |

|

Well I ran her down the road at hwy speeds and above, all good in the hood. I also did brakes front and rear, new tires, clutch & brake fluid flush, oil change, new gear oil in the rear, it's like riding on a New Machine  The true test will be NEXT time you take it apart.......if it still looks the same then all was "good in the hood" |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bronxboy

|

|

« Reply #25 on: July 29, 2016, 12:45:57 PM » |

|

Well I ran her down the road at hwy speeds and above, all good in the hood. I also did brakes front and rear, new tires, clutch & brake fluid flush, oil change, new gear oil in the rear, it's like riding on a New Machine  The true test will be NEXT time you take it apart.......if it still looks the same then all was "good in the hood" She is coming apart again in about 15,000 miles and will get New Dampners, New Flange, New Spiral Gear, then I will be good for awhile. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bighead

|

|

« Reply #26 on: July 29, 2016, 04:41:18 PM » |

|

Pulled the rear from my Bee today and all looks great NO visible wear  120k+  did find a problem though  Dampners are toast but hey no spline problems anywhere  Dampners ordered will mount new tire while I wait for the Dampners. And put new pads on. Needless to say I was very pleased to see this. |

|

|

|

|

Logged

Logged

|

1997 Bumble Bee

1999 Interstate (sold)

2016 Wing

|

|

|

|

Chrisj CMA

|

|

« Reply #27 on: July 30, 2016, 05:05:05 AM » |

|

Pulled the rear from my Bee today and all looks great NO visible wear  120k+  did find a problem though  Dampners are toast but hey no spline problems anywhere  Dampners ordered will mount new tire while I wait for the Dampners. And put new pads on. Needless to say I was very pleased to see this. I hope you ordered the dampeners for the Interstate. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Bighead

|

|

« Reply #28 on: July 30, 2016, 08:17:57 AM » |

|

Pulled the rear from my Bee today and all looks great NO visible wear  120k+  did find a problem though  Dampners are toast but hey no spline problems anywhere  Dampners ordered will mount new tire while I wait for the Dampners. And put new pads on. Needless to say I was very pleased to see this. I hope you ordered the dampeners for the Interstate. Yep |

|

|

|

|

Logged

Logged

|

1997 Bumble Bee

1999 Interstate (sold)

2016 Wing

|

|

|

|