As you can see in the picture, the cable to the left is much longer and I want to dress/route it like the other one. The problem cable is the pull. I ordered new Motion Pro stock cables for the bike, using the Valkyrie handlebars and controls. Turned out the stock length for the "push" cable was just fine, but for the "pull" cable it was ~7" too long unless I routed it by way of the taillight and back around.

So, I started looking at what needed to be done to shorten it without having to special order a new one of a shorter length. I still had the old cable so decided to experiment with removing the various adjusters and other metal parts. Turned out to be quite easy so moved to the new one. In order to remove any portion of the cable housing you have to cut off the small lead nub on one end, creating a new problem....how to replace that lead nub. I shortened the cable by removing 2" from the lower portion and 5" from the upper section of the cable housing. There's an adjuster a short distance beyond the center, the lower portion is the section of housing below that adjuster. The upper portion is from the controls down to the adjuster. Before cutting anything(used a Dremel tool with a cutting disk), make sure you measure how much cable extends beyond the housing. Well, I got the housing shortened and tested the length before inserting the cable. Perfect! Now....about that lead nub. I devised a method of creating one that turned out just fine.

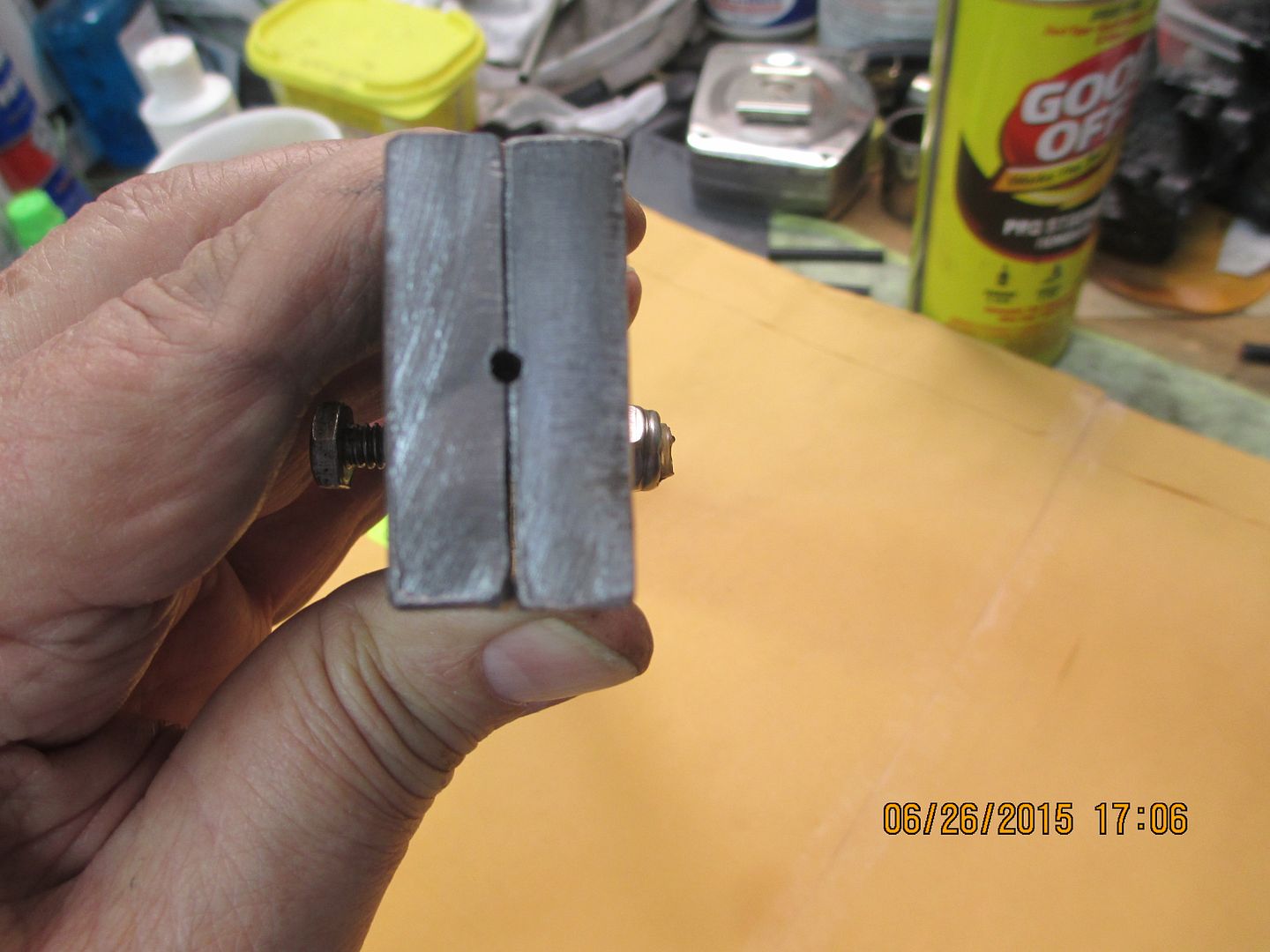

Using some scrap aluminum, I made a sandwish of two sections of it. Drilled all the way through for a bolt to clamp them together. Then when tightened, I drilled a second hole about 2/3 of the way through. That's where the solder will be placed to melt into the shape of the lead nub. Next, about a 3/32" diameter hole was drilled where the two pieces come together. That's where you insert the cable.

Hole in the end for the cable to be inserted.

I propped up a Bernz torch and put my device in the vise right above it. I first cleaned the end of the cable with some carb cleaner, then inserted it in the hole in the end as shown with a short piece in the picture. Next, with the cable in place, I used a jeweler's screwdriver to sorta fray out the wires in the cable while it's still visible in the larger hole where the lead will go. I then packed in some regular plumber's paste flux and fired up the torch. After the flux starts to boil and bubble, you know it's hot enough so I remove the heat from underneath and held the flame a bit farther back and started to feed the solder; 50% tin, 50% lead. It melts and fills the hole where you had packed in the flux. When it was full I used a knife to scrape away the excess on top, then removed the flame. I held the calbe in place so it wouldn't pull out while the lead was still melted, but it was only seconds before it was solid. I let it cool for a bit while cleaning up around the area.

Here's the completed project. On the left is from the Motion Pro factory, on the right is from the Schmidt factory. After a little filing, smoothing, sizing it to fit in the right hand grip/throttle tube, I assembled the right side throttle control and attached the other end to the carb bell crank. Works fine and I didn't have to buy a different cable. Love it when a plan comes together. Took me less than 1/2 hr. to make the lead nub, took me longer to actually dress it down to fit and work smoothly.

The pictures show the bolt as not being tightened down. You do need it really tight so the two pieces don't move. Once you're done melting the solder and it has cooled, just remove the bolt and you can pry the device apart. I found I still had to lay the smaller top section on a slightly open vise and tap the lead slug out with a punch. I was quite pleased with my apparatus, I could actually use smaller holes for the lead and cable but being my first venture of this nature...it worked great. Now I have to pull the carbs out part way to attach the choke cable. Not really looking forward to that.

By the way, in the first picture you can see one of the two coils. I replaced the original 1200 coils with coils off a Valkyrie. Works great, engine fires right up.