|

brillo1542

|

|

« on: July 22, 2011, 03:41:53 PM » |

|

I was working on the last caliper today changing my brake pads when I ran into a large problem. Unbeknownst to me, the hanger pin (holding the pads) had frozen. I inserted my allen socket and turned it to remove the pin. The allen socket rounded the inside of the pin!! Thinking I wasn't about to be beaten, I removed the caliper and locked a set of vice grips onto the pin shaft. No deal. It wouldn't budge. Now, what do I do? Of course, I am planning on going on a 1000 mile trip next weekend, so the timing of this problem couldn't be better.

I hope others have had the same problem and can give me their advice.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Thunderbolt

|

|

« Reply #1 on: July 22, 2011, 03:54:38 PM » |

|

on the threads and give it a couple of raps with a hammer. Let it sit over night and try the vise grips again.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

da prez

|

|

« Reply #2 on: July 22, 2011, 03:55:45 PM » |

|

Brillo, Since you have it out. a little wd and a small hammer , and tap on it. Do not beat it, you should hear a slight change in the sound. Then try to tighten, then loosen. If it starts to move, continue to loosen and tighten. Do not get in a hurry.If you feel it binding, go the opposite way, and keep it wet with wd40. I have used this method for many years.

good luck da prez

|

|

|

|

|

Logged

Logged

|

|

|

|

|

brillo1542

|

|

« Reply #3 on: July 22, 2011, 04:00:43 PM » |

|

Of course. Why didn't I think of that. I will be doing a tap dance on it and leave it overnight in WD40.

Thanks.

|

|

|

|

|

Logged

Logged

|

|

|

|

fudgie

Member

Posts: 10651

Better to be judged by 12, then carried by 6.

Huntington Indiana

|

|

« Reply #4 on: July 22, 2011, 06:42:06 PM » |

|

Anti seize it before you put another one in there.

I anti seize every bolt I take off. Makes it alot easier next time.

|

|

|

|

|

Logged

Logged

|

Now you're in the world of the wolves... And we welcome all you sheep... VRCC-#7196 VRCCDS-#0175 DTR PGR |

|

|

|

YoungPUP

|

|

« Reply #5 on: July 22, 2011, 06:44:41 PM » |

|

Had the same problem last spring. i was lucky enough to get the pin out, but make sure to be generous with the antiseize when it goes back together.  |

|

|

|

|

Logged

Logged

|

Yea though I ride through the valley of the Shadow of Death I shall fear no evil. For I ride the Baddest Mother F$#^er In that valley!

99 STD (Under construction)

|

|

|

|

Ricky-D

|

|

« Reply #6 on: July 23, 2011, 08:06:58 AM » |

|

I would suggest not returning that same bolt to the caliper.

With the ruined hex in the end of the bolt you would be asking for the same problem later on!

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

Gryphon Rider

Member

Posts: 5234

2000 Tourer

Calgary, Alberta

|

|

« Reply #7 on: July 24, 2011, 12:14:58 AM » |

|

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RP#62

|

|

« Reply #8 on: July 24, 2011, 01:25:09 PM » |

|

Anti-sieze everywhere? At first thought it seems good, because you don't want stuck hardware. You would think we use that all the time for military and aircraft applications. Nope.

Threaded fasteners need some friction. If you had a perfectly friction-free nut and bolt, you could torque it, and it would immediately unscrew. Adding a lubricant such as moly-sulfide paste will reduce the ability of fasteners to stay fastened.

Consider using anti-sieze only where specified. For military gear, we use the weaker grades of Loctite, as it seals out the causes of corrosion that make fasteners sieze. It adds a little vibration protection, too. The blue Loctite in a stick is a good choice for motorcycle hardware.

And, if there is no additional material specified for threaded fasteners, you may want to use nothing at all. If you have the unbeatable urge to add something to the threads, try medium strength or weaker Loctite like that blue stick.

Pluggy

Its not just friction. The bolt stretches when torqued and the elasticity of the bolt acts as a spring that keeps tension on the joint and keeps it from backing out. Lubing the threads with with either anti-seize or oil can result in an over-torque, that's why in aircraft applications anyway, the manual will either specify a "wet" torque value or a "dry" torque value or indicate that the given torque value is to be reduced by a given percent if lube-torqued. I've dealt with some applications where the book specifies a nominal torque, then tells you to continue to torque until the bolt has stretched .005". I will always put something on the threads to prevent corrosion. I only use loctite if it can't be properly torqued - i.e. where the proper torque for that size fastener results in too much clamping force for the particular applicaiton. If its something that I thought would kill me if it comes loose, I'd probably drill the head and safety-wire it. -RP |

|

|

|

|

Logged

Logged

|

|

|

|

|

YoungPUP

|

|

« Reply #9 on: July 24, 2011, 05:46:26 PM » |

|

Ok, since there are educated folk here, whats the plan for putting fasteners into dissimilar metals, (ie our steel alternator bolts into the aluminum block) antisieze? locktite? butter??? How do you keep them from welding themselves together without messing up the torquing ability of the bolt.

|

|

|

|

|

Logged

Logged

|

Yea though I ride through the valley of the Shadow of Death I shall fear no evil. For I ride the Baddest Mother F$#^er In that valley!

99 STD (Under construction)

|

|

|

|

RP#62

|

|

« Reply #10 on: July 25, 2011, 07:37:05 AM » |

|

Hey, RP. Yes, a bolt is like a spring, it has to be set to the right tension. If you want to see a really shake-proof vehicle, look at a Model T Ford. Every fastener on the chassis and suspension has a castelled nut and cotter pin. Our Model T may have a few body rattles, but the chassis is together solid. That's what 1910 roads required, I suppose.

The most I've seen is the prop bolts on a Piper Apache with the Doyne conversion. They have castellated nuts with fiber inserts, roll pins go through to secure the castellated nuts, then the roll pins are safety wired in place with .050" safety wire. It used to make me think holy crap, if they're that worried about it, should I be flying it. -RP |

|

|

|

|

Logged

Logged

|

|

|

|

|

RP#62

|

|

« Reply #11 on: July 25, 2011, 07:44:29 AM » |

|

Ok, since there are educated folk here, whats the plan for putting fasteners into dissimilar metals, (ie our steel alternator bolts into the aluminum block) antisieze? locktite? butter??? How do you keep them from welding themselves together without messing up the torquing ability of the bolt.

Just about anything to coat the threads - engine oil, anti-seize, a commercial corrosion preventative, or as Pluggy indicated, loctite. I tend to go with anti-seize (and reduce the torque accordingly), because I've had more trouble getting fasteners out than keeping them in. If its in a corrosion prone area, I'll put corrosion preventative on the shank of the bolt in addition to the anti-seize on the threads. -RP |

|

|

|

|

Logged

Logged

|

|

|

|

|

Ricky-D

|

|

« Reply #12 on: July 25, 2011, 08:19:22 AM » |

|

On the Valkyrie you also need to consider what type of wrenching system is needed to tighten/loosen the bolt/screw.

With phillips heads and socket heads you definitely do not want any trouble when trying to get them out, so an anti-seize is really important.

The consideration for Locktite and motorcycles is mostly related to vibration. This is not relevant to the Valkyrie for the most part.

***

|

|

|

|

|

Logged

Logged

|

2000_Valkyrie_Interstate

|

|

|

|

da prez

|

|

« Reply #13 on: July 25, 2011, 12:36:01 PM » |

|

In some cases I have used teflon paste. It seems to be kind of a neutral ,will not corrode and will loosen when needed. Also, pipe dope (thread sealer) and teflon tape work well in some situations.

It is always (or usually) best to follow manufacturer standards. With the VRCC, some one has usually found a better way or method to do the jobs at hand. Many years of practicle experience exists in this group.

da prez

|

|

|

|

|

Logged

Logged

|

|

|

|

|

The Anvil

|

|

« Reply #14 on: July 25, 2011, 01:17:29 PM » |

|

Ok, since there are educated folk here, whats the plan for putting fasteners into dissimilar metals, (ie our steel alternator bolts into the aluminum block) antisieze? locktite? butter??? How do you keep them from welding themselves together without messing up the torquing ability of the bolt.

I wouldn't use locktite. It will form a barrier but it can also gum up threads and repeated applications over time can cause problems. There are commercially available compounds like Noalox that do a pretty good job of minimizing dissimilar metal corrosion. In aviation we use a lot of mastinox, though I wouldn't recommend it. On brake parts I like to use moly disulfide for anti-seize because it stands up to heat and pressure so well. I'm unaware if it has specific dissimilar corrosion preventing properties but I've been using it for years and never had a problem with that. Also, the hangar pins are cadmium plated (for corrosion resistance) from the factory. When you take them out and reinsert them you wear a little cad plating off each time so it's not a bad idea to replace them once in a while if you can. Failing that, regular application of anti seize also helps keep the cad plating intact during removal and installation. |

|

|

|

|

Logged

Logged

|

Boxer rebellion, the Holy Child. They all pay their rent.

But none together can testify to the rhythm of a road well bent.

Saddles and zip codes, passports and gates, the Jones' keep.

In August the water is trickling, in April it's furious deep.

1997 Valk Standard, Red and White.

|

|

|

|

RonW

|

|

« Reply #15 on: July 25, 2011, 02:58:20 PM » |

|

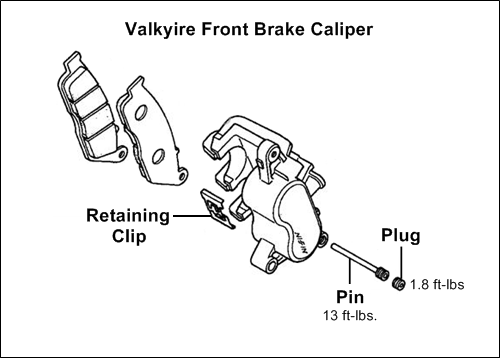

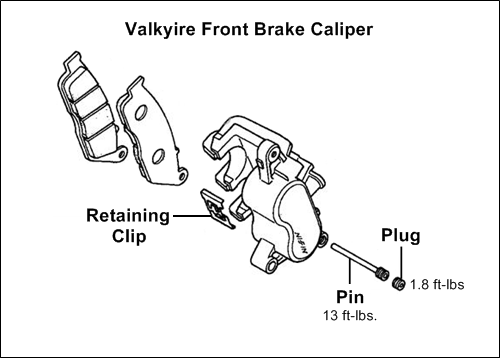

I heard it happens frequently, but it's always puzzled me why a hanger pin would seize up. I know the front calipers are bolted low to the road and susceptible to road grit, but on the other hand, the hanger pin's torque value is so low. I assume that high torque isn't necessary here because the pin doesn't clamp two metal parts together. Its shaft just provides a pivot for the brake pads. The pin is also backed up by a plug to keep it in place. Asides from the threads of the pin wearing out, I'm thinking (uh-oh) that the pin gradually fatigues and develops a sag on its shaft which stresses the thread on the pins, in turn, the stressed threads contributes to the seizing. By the same token, would new retaining clips prevent the weight of the brake pads from sagging the shaft of the hanger pin? (Diagram below for the benefit of new people whom might be following the discussion.)  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

The Anvil

|

|

« Reply #16 on: July 25, 2011, 03:12:51 PM » |

|

I heard it happens frequently, but it's always puzzled me why a hanger pin would seize up. I know the front calipers are bolted low to the road and susceptible to road grit, but on the other hand, the hanger pin's torque value is so low. I assume that high torque isn't necessary here because the pin doesn't clamp two metal parts together. Its shaft just provides a pivot for the brake pads. The pin is also backed up by a plug to keep it in place. Asides from the threads of the pin wearing out, I'm thinking (uh-oh) that the pin gradually fatigues and develops a sag on its shaft which stresses the thread on the pins, in turn, the stressed threads contributes to the seizing. By the same token, would new retaining clips prevent the weight of the brake pads from sagging the shaft of the hanger pin? (Diagram below for the benefit of new people whom might be following the discussion.)  Could be over torquing too, or dissimilar metal corrosion (aluminum caliper body, steel pin). |

|

|

|

|

Logged

Logged

|

Boxer rebellion, the Holy Child. They all pay their rent.

But none together can testify to the rhythm of a road well bent.

Saddles and zip codes, passports and gates, the Jones' keep.

In August the water is trickling, in April it's furious deep.

1997 Valk Standard, Red and White.

|

|

|

Valker

Member

Posts: 3049

Wahoo!!!!

Texas Panhandle

|

|

« Reply #17 on: July 25, 2011, 03:16:38 PM » |

|

I tried to order the pins and plugs. Local dealer told me they were no longer available. Anybody else get this? Maybe a generic replacement? Maybe a high school parts guy?  |

|

|

|

|

Logged

Logged

|

I ride a motorcycle because nothing transports me as quickly from where I am to who I am.

|

|

|

|

The Anvil

|

|

« Reply #18 on: July 25, 2011, 03:18:37 PM » |

|

I tried to order the pins and plugs. Local dealer told me they were no longer available. Anybody else get this? Maybe a generic replacement? Maybe a high school parts guy?  Well I think this caliper was used on a LOT of bikes, not just Hondas either. |

|

|

|

|

Logged

Logged

|

Boxer rebellion, the Holy Child. They all pay their rent.

But none together can testify to the rhythm of a road well bent.

Saddles and zip codes, passports and gates, the Jones' keep.

In August the water is trickling, in April it's furious deep.

1997 Valk Standard, Red and White.

|

|

|

|

RonW

|

|

« Reply #19 on: July 25, 2011, 04:02:08 PM » |

|

Could be over torquing too.....

Definitely. You could never rule out what the PO or the last mechanic did intentionally or unintentionally. |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|

RonW

|

|

« Reply #20 on: July 25, 2011, 04:16:56 PM » |

|

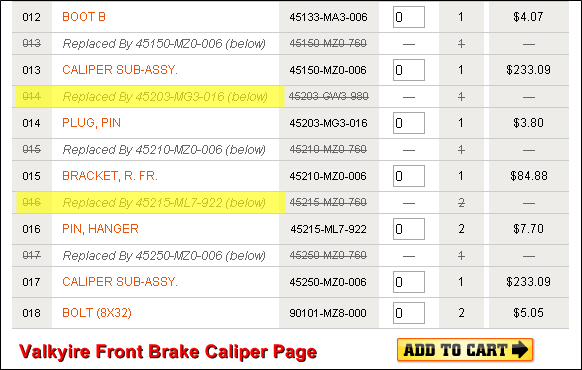

I tried to order the pins and plugs. Local dealer told me they were no longer available....

The counter person might have been thrown off by the " Replaced By...." note in the OEM screen shot below. The dummy. If you don't mind the suggestion, why don't you instead order the parts yourself. The size of the shipped package will fit in your mailbox. Same price as ordered from the dealership. However, be sure to double check shipping rates quoted by the online OEM parts retailer. I recommend that you request your items be shipped US postal service, or if that's not optional, then schedule a pickup at the nearest FedEx or UPS holding station to pickup at your own convenience.  |

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

Valker

Member

Posts: 3049

Wahoo!!!!

Texas Panhandle

|

|

« Reply #21 on: July 25, 2011, 04:28:29 PM » |

|

Thanks.

|

|

|

|

|

Logged

Logged

|

I ride a motorcycle because nothing transports me as quickly from where I am to who I am.

|

|

|

|

RonW

|

|

« Reply #22 on: July 25, 2011, 04:37:28 PM » |

|

Btw, if you do schedule a pickup at FedEx or UPS, the way it's done is you go to their website after the online retailer assigns your item a tracking number. Do the required navigation at the shipper's website and punch in your tracking number, etc. Disregard if you already knew this. It's just that when I posted that I only recently discovered that there was such a thing as pickup stations, I got laughed at. I'll never recover oh boy.

|

|

|

|

|

Logged

Logged

|

2000 Valkyrie Tourer

|

|

|

|